Top 5 Reasons Your Lingerie Samples Fail (And How to Fix Them)?

You've poured your heart into a new lingerie design. You send it off to the factory, buzzing with excitement. But when the first sample arrives, your heart sinks. The fit is wrong, the color is off, and it just looks... cheap. Now you're facing costly revisions, frustrating delays, and a communication breakdown with your manufacturer.

Lingerie samples typically fail for five preventable reasons: a vague tech pack, misunderstanding the fabric properties, inaccurate color and print specifications, ambiguous construction details, and overlooking the importance of trims. Fixing these requires obsessive detail in your documentation and a proactive manufacturing partner.

The sampling stage is where your vision meets reality. It's the single most critical phase in the entire production process. A successful sample is the product of two things: crystal-clear communication (from you) and professional execution (from your manufacturer). At HAVING (China) Ltd., we see ourselves as your co-creators. We believe a perfect sample starts with a perfect plan. I've seen too many brilliant ideas fail at this stage due to simple, avoidable mistakes. This guide breaks down the top 5 reasons samples fail and gives you the insider knowledge to get it right the first time.

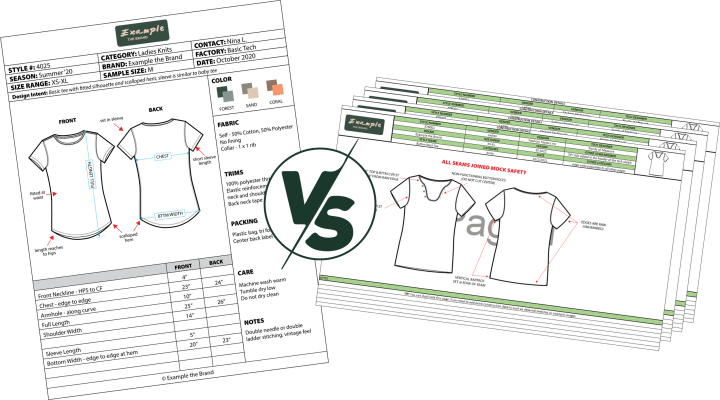

Failure #1: Is Your Tech Pack a Vague Wish List?

You send your manufacturer a beautiful sketch, a few inspirational photos, and a basic size chart. You expect them to fill in the blanks, but instead, you get a sample that reflects their guesswork, not your vision.

An incomplete or ambiguous tech pack is the #1 cause of sampling failure. If your size chart is missing key measurements, your stitch types aren't specified, or your material list is incomplete, the factory is forced to make assumptions. These assumptions are almost always different from your own, leading to immediate failure.

I cannot overstate this: your tech pack is the legal and technical blueprint for your product. Last month, a new brand sent us a tech pack for a bralette that listed the main material as "black lace." There are thousands of types of "black lace"—Chantilly, Leavers, Jacquard, stretch, non-stretch... which one did they mean? A less experienced factory might just grab the cheapest one. Our process, as part of our OEM/ODM services, is to stop and ask. We went back to the client and guided them to provide a specific reference swatch or supplier code. This proactive communication prevented a certain failure. Your tech pack must be so detailed that a stranger in another country could read it and create your exact product without asking a single question.

From Vague to Actionable: The Tech Pack Test

| Vague Instruction (Fails) | Specific Instruction (Succeeds) |

|---|---|

| **Size Chart:** "Size M" | **Size Chart:** "Size M: 1/2 Band (relaxed) = 35cm, Cup Depth = 15cm..." (with a full list of measurements) |

| **Materials:** "Pink elastic" | **Materials:** "12mm plush-back picot elastic, Supplier XYZ, Item #123, Pantone 14-1911 TCX" |

| **Construction:** "Sew together" | **Construction:** "Use 3-thread flatlock seam on all side seams, 14 SPI. Bar-tack at strap join." |

Failure #2: Did You Misunderstand the Fabric's Personality?

In your mind, you pictured a soft, drapey bralette. The sample you received is stiff and structured. The factory says they used the "same" fabric type you requested, but the result is completely wrong.

Every fabric has a unique personality defined by its weight, stretch, and drape. Even a small difference—a fabric with 15% spandex instead of your intended 20%—can completely change the fit and feel of a garment. Using an unapproved substitute fabric is a guaranteed path to a failed sample.

Fabric is a living, breathing thing. You cannot specify "95% Cotton / 5% Spandex" and expect a consistent result. The knit structure, the finishing process, and the specific brand of spandex fiber all have a huge impact. I once had a client who insisted on a very specific, expensive Japanese modal. To save time, another factory she was testing made a sample with a standard modal. The sample looked okay on the table, but the moment the fit model put it on, it was a disaster. The standard modal didn't have the same fluid drape and recovery. It hung lifelessly. This is why you must either provide your own sample fabric or approve a swatch from the factory's sourcing team before the first sample is ever cut.

Failure #3: Is Your Color a Vague Idea or an Exact Science?

You asked for a "dusty rose" panty. The sample that arrived is a bright, bubblegum pink. The factory is confused—they thought that's what you meant.

Color is not subjective in manufacturing; it is a science. Without providing a universal color standard, like a Pantone TCX (Textile Cotton eXtended) code, you are leaving the most important visual element of your design entirely to chance. The same goes for prints; you must specify the exact repeat size and placement.

Computer screens lie. The "dusty rose" on your MacBook screen looks completely different on my Windows PC here at the factory. It will look different again under our factory lighting. The Pantone TCX system is the universal language of color in the textile industry. When you give me the code "Pantone 14-1714 TCX," I can send that to any dye house in the world, and they will produce that exact shade. For prints, the common failure is scale. A brand sent us a beautiful leopard print pattern, but they didn't specify the repeat size. The factory they tested before us printed it so large that a single panty only had two spots on it! Your tech pack must include the print file with the exact dimensions of the repeating pattern.

Failure #4: Did You Assume the Factory Knows How to Sew?

The sample looks okay from a distance, but up close the seams are bulky and the edges are scratchy. The garment lacks that refined, high-quality feel you envisioned for your brand.

You cannot assume a factory will use high-end construction methods unless you explicitly demand them. If your tech pack doesn't specify a "flatlock seam," you will likely get a standard, bulkier "overlock seam." The comfort and quality of your bras and panties is determined by these tiny but critical details.

This is a classic example of getting exactly what you asked for, not what you wanted. A standard overlock seam is fast and strong, and it's the default for most basic garments. But for lingerie that sits right against the skin, it can be irritating. A flatlock seam is sewn so that the fabric edges lie flat, creating a much smoother, more comfortable feel. It's a slower, more expensive process. A good manufacturer, guided by a philosophy like our "body-before-fabric," will often suggest these better techniques. But ultimately, it is your responsibility as the designer to specify them in the tech pack. If you don't, the factory will default to the fastest, most cost-effective method.

Failure #5: Did You Treat Trims as an Afterthought?

The fabric is perfect, the color is right, the fit is great... but the straps keep slipping, and the hook-and-eye feels cheap and scratches the skin. The entire garment is let down by its final components.

Trims—elastics, hardware, and closures—are functional heroes, not just decorative extras. A cheap, low-quality slider will slip, a poorly-made hook-and-eye will scratch, and a weak elastic will lose its stretch. Specifying high-quality, tested trims is essential for a successful sample.

This happens all the time. A brand will spend a fortune on a beautiful, certified organic fabric and then approve a standard, cheap plastic ring and slider for the straps. After a few wears, the slider loses its grip, and the customer is left with constantly falling straps and a negative perception of the brand. We always encourage clients to think of trims as a key part of the user experience. We source high-quality, coated metal hardware that locks in place. We use soft-backed, plush elastics that feel good against the skin. Every single component matters. A failed trim is a failed product.

Conclusion

A perfect sample is not a matter of luck. It is the direct result of a meticulously detailed tech pack and a partnership with an experienced manufacturer who asks the right questions. Your job is to provide the perfect blueprint; our job is to bring it to life, flawlessly.

Frequently Asked Questions (FAQ)

1. How many rounds of samples are normal?

For a new design, 2-3 rounds of samples are very common to perfect the fit and construction. The first sample (prototype) is to check the basic concept. The second sample is a "fit sample." The final "pre-production sample" (PPS) is the one you will approve for bulk production.

2. Why do I have to pay for samples?

Sampling is a highly skilled and labor-intensive process that uses expensive materials and the time of your factory's best pattern makers and sewers. Most reputable factories charge for samples to cover these costs. Many will offer to credit some or all of the sampling fees back to you if you place a bulk order.

3. What is a "lab dip"?

A lab dip is a small swatch of your chosen fabric dyed to match your specified Pantone TCX color. The dye house creates this for your approval before they dye all the fabric for your bulk order. It is a critical step to ensure color accuracy.

4. What if the factory cannot source the exact fabric or trim I want?

This is common. A good manufacturer will be transparent about this and will proactively source 2-3 of the closest available alternatives for you to choose from. They should provide you with detailed specs and physical swatches of these alternatives for your approval before making the sample.