Top 5 Lingerie Manufacturing Trends for 2026: What Smart Brands Are Demanding Now?

You're planning your upcoming collections, focusing on new colors and styles. But in the background, the entire manufacturing landscape is shifting. Are you designing for the future, or are you at risk of being left behind by smarter, faster, and more innovative brands?

Looking ahead to 2026, smart brands are demanding more than just a product; they're demanding a future-proofed supply chain. The top five manufacturing trends are: radical material traceability, next-generation seamless technology, "invisible" smart fabrics, hyper-personalization through AI, and a design philosophy of "adaptive comfort" for all body types.

Being a manufacturer gives you a unique window into the future. You see the sample requests and the tech pack specifications from the world's most forward-thinking brands months or even years before those products hit the market. And I can tell you, the conversation is changing. It's no longer just about cost per unit. It's about data, technology, and a completely new definition of comfort and sustainability. At HAVING (China) Ltd., we are actively investing in these future-facing technologies because we know this is where the market is going. This isn't a vague prediction; this is what your smartest competitors are already demanding.

Trend #1: Is "Sustainable" Evolving into Radical Traceability?

For the last few years, having a GRS or OCS certificate was enough. But smart brands know that in 2026, customers will demand more. They don't just want to know that a product is recycled; they want to know its entire life story.

Yes. The new standard is "Radical Traceability." Smart brands are demanding a fully transparent supply chain, using technologies like blockchain and digital product passports (DPPs) to allow customers to scan a QR code and see the entire journey of their garment, from the recycled plastic bottle to the factory floor.

This is a huge shift from a simple certification logo. It's about providing undeniable proof. We are already in discussions with tech partners to integrate this into our workflow. Imagine your customer scanning a tag on a piece of your sustainable swimwear and seeing a map that shows where the post-consumer plastic was collected, the date it was processed into yarn, and even a greeting from the team leader who oversaw the sewing of that batch at our factory in Shantou. This isn't science fiction; the European Union is already phasing in requirements for DPPs. Brands that build this level of transparency now will win the absolute trust of the next generation of consumers. It moves sustainability from a claim to an immersive, verifiable experience.

What Radical Traceability Means for You

| The Old Way (2023) | The New Standard (2026) |

|---|---|

| A hangtag with a GRS logo. | A QR code linking to a digital passport. |

| Trusting the factory's certificate. | Verifying the entire journey with blockchain-secured data. |

| A generic "Made in China" label. | Telling the specific story of the skilled artisans and the factory that made the garment. |

Trend #2: Is "Seamless" Becoming 3D-Knit Body Architecture?

For years, seamless underwear meant a simple, comfortable garment made on a circular knitting machine. It was great, but the technology had its limits. Are you still thinking of seamless as just basic panties?

Absolutely. The next frontier is 3D-Knit "Body Architecture." Smart brands are moving beyond simple seamless tubes and using advanced 3D-knitting machines to create garments with integrated support, contouring, and breathability zones—all in one seamless piece. It's less like making clothing and more like printing a second skin.

This technology is a game-changer, and it perfectly aligns with our "body-before-fabric" philosophy. Traditional manufacturing is "subtractive"—you cut pieces from a flat sheet of fabric and sew them together. 3D knitting is "additive"—it builds the garment thread by thread, allowing us to engineer its properties with incredible precision. For our shapewear clients, this is revolutionary. We can program a machine to create a panel with firm compression for the tummy, a gentle lifting knit for the rear, and a breathable mesh texture at the lower back, all without a single seam. This results in unparalleled comfort and performance, and it also dramatically reduces fabric waste. Brands that embrace this technology will offer a level of comfort and fit that traditional cut-and-sew methods can't match.

Trend #3: Is Your Lingerie Becoming "Smarter" Than You Think?

For a century, lingerie has been a passive product. It looks good, it feels good, but it doesn't do anything. Are you still designing passive products for an active world?

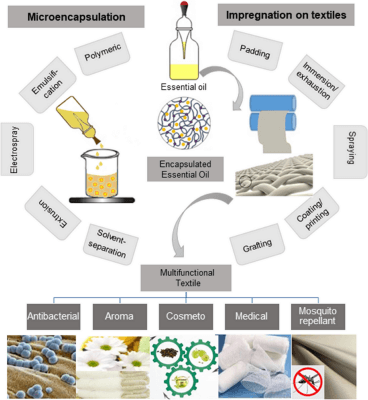

Without a doubt. The rise of "invisible tech" is embedding functionality directly into the fibers of the garment. Smart brands are demanding fabrics with integrated benefits like body temperature regulation, moisture-activated skin conditioning (micro-encapsulation), and even biometric feedback for a new generation of smart garments.

This is moving beyond the gimmick stage and into real, marketable benefits. We are actively sourcing fabrics with these embedded technologies for several forward-thinking clients. For example, we're working with yarns that have thermo-regulating properties, helping to keep the wearer cool when they're hot and warm when they're cold. Another exciting area is micro-encapsulation, where yarns are infused with millions of micro-capsules containing skin-friendly substances like aloe vera or caffeine, which are gradually released through friction as the garment is worn. While the dream of a bra that tracks your heart rate is still niche, these practical, wellness-focused smart fabrics are a real and growing demand. Brands that can credibly claim their lingerie "cares for your skin" or "regulates your temperature" will have a powerful competitive advantage.

Trend #4: Will AI Make Standard Sizing Obsolete?

Brands have always struggled with sizing, creating a limited range (S, M, L) that forces customers to compromise. Are you still forcing your customers to fit into your sizes, or are you making sizes that fit your customers?

Yes, hyper-personalization powered by AI is the future. Smart brands are starting to use AI-driven body scanning apps and data analysis to offer made-to-measure or micro-sized collections. This moves away from a few standard sizes to a model that offers a "perfect fit" for a much wider range of body types.

This trend is still in its early stages, but it's developing fast. The model works like this: a brand partners with an AI company that provides a smartphone-based body scanning tool. A customer takes a few photos, and the AI generates their precise measurements. This data can be used in two ways. The ultimate vision is true "made-to-order," where we would produce a one-off garment to their exact specs. More immediately, brands are using this data to create "micro-size" clusters. Instead of 5 sizes, they might offer 25 more nuanced sizes based on the real-world data of their customers. As a manufacturer, our role is to become more agile, using our OEM expertise to create flexible production lines that can handle these more complex, data-driven size ranges. Brands that crack this code will effectively eliminate returns due to poor fit.

Trend #5: Will "Inclusivity" Mature into "Adaptive Comfort"?

For years, inclusivity meant extending size ranges. While crucial, that was only the first step. Are you still just adding larger sizes, or are you fundamentally rethinking the design of your products for a wider range of human experiences?

The new paradigm is "Adaptive Comfort." Smart brands are designing lingerie that adapts to the changing needs of a body throughout life. This includes products for post-surgery recovery, menopause, sensory sensitivities, and people with disabilities. It's a move from passive inclusivity to active, functional problem-solving.

This is a profoundly meaningful trend and a huge market opportunity. We are receiving more and more requests for thoughtful, adaptive designs. This includes bras with front closures for those with limited mobility, seamless and tag-less designs for customers with sensory sensitivities, and panties made with special moisture-wicking fabrics for women experiencing menopausal hot flashes. It requires a deeper level of empathy in design and a manufacturer who understands the technical requirements, like using ultra-soft seams or certified skin-safe materials. Brands that authentically serve these overlooked communities are building incredibly loyal customer bases and creating products that genuinely improve people's lives.

Conclusion

The future of lingerie manufacturing is intelligent, transparent, and deeply personal. Brands that embrace these five trends today will not only stay relevant; they will become the leaders of the industry tomorrow.

Frequently Asked Questions (FAQ)

1. What is a Digital Product Passport (DPP)?

A Digital Product Passport is a digital record of a product's entire lifecycle. For clothing, it can include information about the raw materials, the factory where it was made, its carbon footprint, and instructions on how to care for and recycle it. The EU is mandating DPPs for textiles to increase transparency and promote a circular economy.

2. Is 3D-knitting the same as 3D-printing?

No. While the concepts are similar (additive manufacturing), 3D-printing for textiles is still highly experimental and often uses plastics to create a fabric-like structure. 3D-knitting uses traditional yarns (like nylon and spandex) on highly advanced knitting machines to build a complete, seamless garment.

3. Are smart fabrics safe to wear?

Yes. Reputable smart fabrics, especially those with micro-encapsulation or thermo-regulating properties, are rigorously tested for skin safety. They are often required to be OEKO-TEX® certified, ensuring they are free from any harmful substances before they can be sold.

4. How can a small brand use AI for sizing?

Small brands can partner with existing tech companies that offer "white-label" body scanning solutions. These can be integrated into e-commerce platforms like Shopify. A brand can start by using the data to better inform their standard size chart before moving to more complex micro-sizing.

5. What is an example of an "adaptive" feature in lingerie?

A great example is a post-mastectomy bra. It is an adaptive garment that often includes features like soft, non-irritating fabrics, pockets to hold a prosthesis, front closures for ease of dressing, and higher side panels for extra coverage and support.