The Waistband Deep Dive: Manufacturing Secrets to a Premium Men's Boxer Brief?

The waistband is the first thing your customer touches and the last thing he forgets. It's the handshake of your product, the billboard for your brand, and the primary source of comfort—or complaint. Yet, for many brands, it remains a complete mystery.

A premium men's underwear waistband is an engineered product, not a simple accessory. Its perceived quality and performance are determined by a precise combination of material science (nylon vs. polyester), branding craftsmanship (jacquard vs. printing), and structural engineering (stitching and construction to prevent rolling). Understanding these secrets is the key to creating a best-seller.

As a manufacturer, I can tell you that the waistband is where a brand's true commitment to quality is revealed. It's often the most expensive single component of a boxer brief. I've seen brands try to save $0.10 on the waistband, only to create a product that rolls, scratches, and loses its shape after a few washes, leading to a flood of bad reviews. At HAVING (China) Ltd., we see the waistband as the "face" of the garment. It's a critical touchpoint that embodies our "body-before-fabric" philosophy. This deep dive will demystify the waistband, giving you the insider knowledge to invest wisely in your brand's most important ambassador.

The Material Duel: Are You Choosing for Feel or Just for Price?

The foundation of any great waistband is the yarn it's made from. You hear terms like nylon, polyester, and microfiber, but what is the real-world difference in terms of comfort, durability, and cost?

The choice of material is a critical trade-off between softness, moisture management, and cost. Nylon offers a soft, premium feel; polyester provides excellent durability and color vibrancy; and true microfiber delivers the best of both worlds at a slightly higher price. Your choice directly impacts the customer's first impression.

This is the first decision we guide our clients through. A brand targeting the high-end market might insist on a nylon or microfiber waistband for its silky, cool-to-the-touch feel. Another brand focused on athletic performance might choose polyester for its superior moisture-wicking and durability. There is no single "best" material, only the "right" material for your specific brand and customer. I once worked with a client who was adamant about using a polyester band to save costs, but their brand was all about luxury comfort. We produced a sample and sent it to them along with a nylon-blend option. The moment they felt the difference in softness and smoothness, they understood the value. The small extra cost was an essential investment in their brand's promise.

Material Breakdown:

| Material | Key Characteristics | Best For |

|---|---|---|

| **Nylon** | Very soft, silky feel. Good stretch and recovery. Smooth surface. | Premium, fashion-focused brands where a luxurious hand-feel is a top priority. |

| **Polyester** | Excellent durability, holds vibrant colors well, great moisture-wicking. Can feel slightly less soft than nylon. | Athletic lines, value-driven brands, and designs with very bright, saturated logo colors. |

| **Microfiber** | An ultra-fine version of nylon or polyester yarns. Extremely soft, lightweight, and breathable. | High-end and performance brands looking for the ultimate combination of softness and function. |

The Art of Branding: Is Your Logo Woven In or Just Printed On?

Your logo on the waistband is your brand's signature. How it's applied is a critical decision that communicates your quality level instantly. Are you building a brand that lasts, or one that fades after a few washes?

The two primary methods for branding a waistband are Jacquard weaving and Screen Printing. Jacquard, which weaves the logo directly into the band, offers a superior, permanent, and premium feel. Printing is a more cost-effective, surface-level application that is less durable over time.

The difference between jacquard and printing is night and day. A jacquard logo has texture and depth; you can feel the quality with your fingertips. It will never crack, peel, or fade. It's a statement of permanence. Screen printing can look great initially, but it's essentially a layer of ink sitting on top of the elastic. With repeated stretching and washing, it will inevitably degrade. For our premium men's underwear clients, we almost always recommend jacquard. However, for a brand on a tight budget, a high-quality, flexible screen print can be a good starting point. Another key detail is the inside of the band. We often use a "brushed-back" or "plush-back" finish, where the inner surface of the elastic is brushed to make it incredibly soft against the skin. This small detail is a secret weapon for creating a loyal customer.

The Key to Comfort: Is Your Waistband Built to Stay Put?

What is the single most annoying problem with a bad pair of boxer briefs? A waistband that rolls, folds, or digs into your waist. This is not a random occurrence; it is a structural failure.

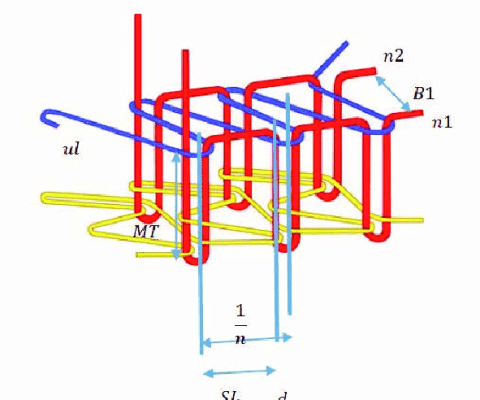

A "no-roll" waistband is the result of smart structural engineering. It relies on the right combination of fabric stiffness (modulus), adequate width (typically 35mm or wider), and specific sewing techniques, like a two or three-needle coverstitch, to securely anchor the band to the garment body and prevent it from collapsing.

This is pure physics. A waistband is under constant tension. If it's too narrow or too flimsy, it has a natural tendency to fold over on itself. A wider band (40-45mm) distributes that pressure over a larger area, making it inherently more stable. But the real secret is in the attachment seam. A simple, single-stitch attachment is a recipe for failure. At our factory, we use specialized multi-needle chainstitch or coverstitch machines for this operation. A three-needle coverstitch, for example, creates two parallel lines of stitching on the outside and a web of thread on the inside. This creates a wide, flat, and secure seam that anchors the band and dramatically reduces its ability to roll. It’s a more time-consuming process, but it’s essential for creating a truly high-quality garment.

The Cost Equation: What Are You Actually Paying For?

So, why does one waistband cost $0.35 and another, seemingly similar one, cost $0.75? The price is a direct reflection of the material, width, and craftsmanship you choose.

Every element of a waistband has a specific cost. The raw material is the base, but the width, the complexity of the jacquard logo, and any special finishes (like brushing) are all significant factors that add up to the final price. Understanding this equation allows you to make strategic trade-offs.

When we develop a new waistband with a client as part of our OEM/ODM services, we are completely transparent about these cost drivers. We can present them with options. For example, moving from a 35mm width to a 45mm width might add $0.08, but it will dramatically improve the comfort and stability. Switching from a simple one-color jacquard logo to a complex, multi-color design might add $0.12. By understanding these variables, you can engineer a waistband that hits the perfect sweet spot between your brand's quality promise and your target cost.

Decoding Your Waistband Quote

| Cost Driver | Low-Cost Option | Premium Option | Approx. Cost Impact |

|---|---|---|---|

| **Material** | Standard Polyester | Brushed-back Nylon or Microfiber | +20-40% |

| **Width** | 30-35mm | 40-50mm | +15-25% |

| **Branding** | 1-Color Screen Print | Multi-Color Jacquard Weave | +30-60% |

| **Finishing** | Standard | Silicone Gripper, Special Softening | +10-20% |

Conclusion

A premium waistband is the single most powerful investment you can make in your men's underwear brand. It is a direct investment in your brand's perceived quality, your customer's comfort, and ultimately, their long-term loyalty.

Frequently Asked Questions (FAQ)

1. What is a "brushed-back" or "plush-back" waistband?

This is a finishing process where the inside surface of the elastic waistband is mechanically brushed to raise the fibers, creating an incredibly soft, plush feel against the skin. It significantly enhances comfort and is a hallmark of a premium garment.

2. What is the MOQ for a custom jacquard waistband?

The Minimum Order Quantity for a custom woven jacquard waistband is typically quite high, often starting at 5,000 to 10,000 meters. This is because setting up the complex jacquard loom is a time-consuming process.

3. Why do some waistbands lose their shape so quickly?

This is usually due to a low-quality elastane (spandex) fiber or a poor knit structure. The waistband loses its "recovery," meaning it stretches out but doesn't snap back to its original size. A good waistband uses high-quality elastane and is engineered for durability.

4. Can you print on a jacquard waistband?

While technically possible, it's generally not done. The beauty of a jacquard waistband is the woven texture of the logo. Printing on top of it would cover that premium detail. The two techniques are usually used as alternatives to each other.