The impact of technology on lingerie manufacturing: A look into the future.

I. Introduction

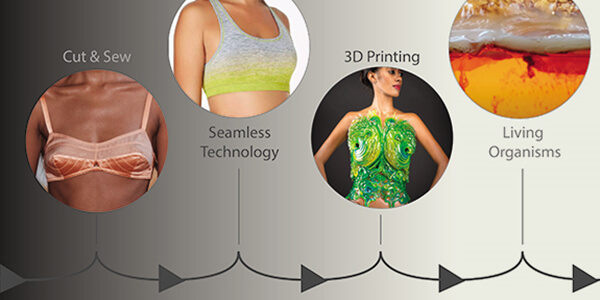

The lingerie industry has undergone significant changes in recent years, with technology playing an increasingly important role in manufacturing. As new technologies emerge and existing ones are refined, the future of lingerie manufacturing looks bright. In this article, we will explore the impact of technology on lingerie manufacturing and look at what the future might hold. From automated production lines to 3D printing, we will examine how technology transforms the lingerie industry and what this means for consumers and manufacturers alike.

II. Current State of Lingerie Manufacturing

Overview of the traditional lingerie manufacturing process

Lingerie manufacturing is a labor-intensive process that involves multiple steps. The standard process begins with designing the lingerie, followed by pattern making, grading, marking, cutting, sewing, and finishing. Each step is carried out by skilled workers who require extensive training and experience to perform their tasks effectively.

Designers create the initial designs and select the materials for the lingerie. Pattern makers then make the patterns for each size, and graders adjust how to create additional sizes. Markers use patterns to lay out the fabric for cutting, and cutters use electric or manual cutting machines to cut the fabric into pieces. Sewers then assemble the pieces using specialized machines and techniques. Finally, finishers add the final touches, such as hooks, eyes, and straps.

This process is time-consuming and costly, requiring a large workforce and significant investment in equipment and materials. However, with technological advancements, the traditional lingerie manufacturing process is transforming.

Discussion of the limitations and challenges of current methods:

Despite the traditional methods being used for decades, the lingerie manufacturing industry faces several limitations and challenges. Some of these include:

- Limited customization options: The traditional manufacturing process limits the range of customization options available to customers. Customers are forced to choose from the limited options available, which may not meet their specific preferences.

- Labor-intensive process: The current manufacturing process is highly labor-intensive, requiring skilled workers to cut, sew and assemble each piece. This makes the process time-consuming and costly.

- Environmental impact: The current manufacturing process has a significant environmental impact. Using synthetic fabrics, dyes, and chemicals contributes to pollution, while waste generated during manufacturing contributes to landfill and water pollution.

- Inconsistent sizing: Despite using size charts, the lingerie sizing needs to be more consistent across brands. This inconsistency makes it difficult for customers to find the right size, leading to returns and customer dissatisfaction.

- Slow production time: The traditional manufacturing process could be faster, with production times taking weeks or months to complete. Companies need help to respond to changes in customer demand and fashion trends.

III. Technology in Lingerie Manufacturing:

Explanation of the impact of technology on lingerie manufacturing:

Technology has revolutionized the fashion industry, and lingerie manufacturing is no exception. New technologies are being used to improve production, reduce costs, and enhance lingerie quality. These advancements have significant implications for the industry, including changes in how lingerie is designed, manufactured, and marketed.

Overview of new technologies being used in lingerie manufacturing:

- 3D printing: 3D printing has made it possible to create intricate and complex designs quickly and easily. This technology can help manufacturers produce customized lingerie at a lower cost.

- Automated sewing machines: Automated sewing machines can perform repetitive tasks faster and more accurately than manual labor. They are used for producing large quantities of lingerie, reducing the need for human workers and improving production efficiency.

- Laser cutting: Laser cutting technology can precisely cut fabric and materials to create intricate designs without damaging them. This method allows for faster and more accurate production and reduces waste.

- Digital pattern-making: Digital pattern-making uses software to create accurate patterns for lingerie designs, which can be quickly and easily modified. This technology streamlines the design process and helps reduce errors and waste.

Discussion of the benefits and potential drawbacks of technology in this industry:

The benefits of technology in lingerie manufacturing are numerous. These advancements can improve product quality, reduce costs, and increase production efficiency. Technology also enables greater customization, allowing manufacturers to create lingerie that meets customers' specific needs and preferences. However, there are also potential drawbacks to consider. Technology may require significant investments in new equipment and training for workers. Additionally, there is a risk that technology could replace human workers, leading to job loss and income inequality. It is essential to carefully weigh the benefits and drawbacks of technology in lingerie manufacturing to ensure that it is used responsibly and sustainably.

IV. Virtual Fitting Technology

Virtual fitting technology explained

Virtual fitting technology refers to software or tools that enable customers to try on clothing virtually, without physically putting on the garment. In the case of lingerie, customers can see how different styles and sizes fit them without going through the traditional fitting process.

Impact on the lingerie industry

Virtual fitting technology is revolutionizing the lingerie industry by providing customers with a more convenient and personalized shopping experience. Customers can try lingerie in the comfort of their homes and see how it fits before making a purchase. This technology also helps reduce the environmental impact of traditional shopping methods by reducing the need for shipping and returns.

Examples of companies using virtual fitting technology

Several lingerie companies have already adopted virtual fitting technology. ThirdLove, for instance, offers a virtual fitting room where customers can answer a few questions about their body shape and receive personalized recommendations for bras. True & Co. provides a Fit Quiz that uses artificial intelligence to recommend the best styles and sizes based on a customer's answers to a few questions.

V. 3D Printing Technology

This section will explain 3D printing technology and its potential for lingerie manufacturing. 3D printing is a process where a three-dimensional object is created by adding layers of material together. This technology has already been used in various industries, including aerospace and automotive, and is now applied to lingerie.

The potential benefits of 3D printing technology in lingerie manufacturing are numerous. It allows for the production of custom-fit lingerie with high accuracy and precision. This means that each garment can be tailored to the unique shape and size of the individual customer, resulting in a more comfortable and flattering fit. Additionally, 3D printing technology can create complex designs and conditions that would be difficult or impossible to produce with traditional manufacturing methods.

Several companies are already using 3D printing technology in lingerie production. For example, the Dutch lingerie brand Van de Velde has developed a 3D scanning and printing system that allows for the creation of custom-fit bras. Another company, Continuum Fashion, has created a line of 3D-printed bras made to order and designed to fit the individual customer perfectly.

While 3D printing technology has great potential in lingerie manufacturing, there are also some drawbacks. One of the main challenges is the cost of the technology and the materials used in the printing process. Additionally, creating a 3D-printed garment can take time, which may not be feasible for companies needing to produce large quantities of lingerie quickly.

Despite these challenges, 3D printing technology is an exciting development in lingerie manufacturing. It has the potential to revolutionize the industry by providing a higher level of customization and precision in the production of garments.

VI. Sustainable Manufacturing Practices

The lingerie industry has been facing increasing scrutiny in recent years over its environmental impact. As such, there has been a growing push towards more sustainable manufacturing practices. This section will discuss the importance of sustainability in the lingerie industry, as well as some of the new technologies being used to achieve it.

Firstly, it is important to recognize the impact that the traditional lingerie manufacturing process has on the environment. From the sourcing of materials to the disposal of unused fabric scraps, the process can be incredibly wasteful. To combat this, many companies are turning to new, sustainable manufacturing practices.

One such practice is the use of recycled materials. Some companies are using recycled fabrics to create their lingerie, while others are turning to recycled plastic to make their packaging. Additionally, many companies are embracing the concept of circular fashion, designing products that are meant to be reused or repurposed rather than thrown away.

There are also new technologies being developed to reduce waste and increase sustainability in lingerie manufacturing. For example, 3D printing can be used to create custom-sized bras, eliminating the need for excess fabric and reducing waste. Digital printing technology can also be used to create intricate designs on lingerie without the use of harmful chemicals.

Several companies have already started implementing sustainable practices in their lingerie production. For instance, H&M's Conscious Collection includes lingerie made from sustainable materials such as organic cotton and recycled polyester. Another example is Naja, a lingerie brand that uses digital printing to create intricate designs on their products without the use of water or toxic chemicals.

Overall, sustainable manufacturing practices are becoming increasingly important in the lingerie industry, and new technologies are being developed to help achieve this goal. By embracing these new practices, companies can reduce waste and lessen their impact on the environment while still creating beautiful and high-quality lingerie.

Ⅶ. Automated sewing machines

Automated sewing machines have revolutionized the lingerie manufacturing process. These machines can perform repetitive tasks faster and more accurately than manual labor, resulting in increased production efficiency and reduced production time. With automated sewing machines, the need for human workers is reduced, making producing large quantities of lingerie easier.

One of the main advantages of automated sewing machines is their ability to produce precise and consistent stitching, resulting in high-quality finished products. The machines are equipped with advanced sensors and cameras that allow them to detect and adjust to changes in fabric thickness, texture, and other variables, ensuring that the stitching is always accurate and consistent.

Another advantage of automated sewing machines is their ability to work around the clock without breaks, significantly increasing production output. The machines also reduce the risk of workplace injuries, as they eliminate the need for manual labor and reduce the amount of physical strain on workers.

Several lingerie manufacturers have already implemented automated sewing machines in their production process. For example, a well-known lingerie brand has adopted automatic sewing machines in their factories, increasing production efficiency and reducing production costs.

Ⅷ. Digital pattern-making

Digital pattern-making technology uses software to create accurate patterns for lingerie designs. This process is faster and more efficient than traditional pattern-making, as it eliminates the need for manual drafting and cutting. Additionally, digital patterns can be easily modified, allowing for quick adjustments to be made to the design.

This technology streamlines the lingerie design process and helps reduce errors and waste, as the digital patterns can be tested and adjusted before being physically produced. It also allows for more complex and intricate designs, as the software can handle more intricate details than traditional manual drafting methods.

Overall, digital pattern-making has the potential to revolutionize the lingerie industry by improving production efficiency, reducing waste, and enabling more creative and intricate designs.

Ⅸ. Future of Lingerie Manufacturing

Technology continuously evolves, and its impact on lingerie manufacturing is expected to become more significant. The industry can expect more automation, sustainability, and customization as technology improves.

One potential development in the future of lingerie manufacturing is using Artificial Intelligence (AI) and Machine Learning (ML) algorithms. These technologies could analyze vast amounts of data, including consumer preferences and body measurements, to predict trends and create personalized designs. This could lead to more efficient and sustainable production and reduce the environmental impact of producing lingerie.

Another potential development is using Virtual and Augmented Reality (VR/AR) in the fitting process. This technology could allow customers to virtually try on lingerie and see how it would fit and look on their bodies before purchasing, reducing the number of returns and improving customer satisfaction.

In addition, 3D printing technology may continue to revolutionize lingerie manufacturing. This technology could allow for faster and more sustainable production of custom-fit lingerie, reducing waste and improving efficiency.

Overall, the future of lingerie manufacturing looks promising, with the potential for more sustainable, efficient, and customized production methods thanks to technological advancements.

Ⅹ. Conclusion

In conclusion, technology is transforming the lingerie industry in exciting and innovative ways. From virtual fitting technology to 3D printing and sustainable manufacturing practices, the possibilities are endless. Automated sewing machines and digital pattern-making are also improving production efficiency and reducing waste.

As we look to the future, it is clear that technology will continue to shape the industry in significant ways. With advancements in materials science, AI, and automation, lingerie manufacturing will become even more efficient and sustainable. Additionally, new technologies will allow for more personalized and customized lingerie designs, catering to the unique needs and preferences of consumers.

Overall, the integration of technology into lingerie manufacturing has the potential to create a more sustainable, efficient, and innovative industry. As companies continue to invest in these advancements, we can expect to see even more exciting developments in the years to come.