The Art of Mesh & Tulle: Using Different Weights, Meshes & Stretches to Create Magic in Lingerie Design?

Have you ever struggled to achieve that perfect balance of support and seduction in your lingerie designs? Many designers face challenges selecting the right mesh or tulle, resulting in garments that either lack structure or sacrifice the delicate transparency that makes lingerie so alluring.

The strategic selection of mesh and tulle fabrics based on weight, stretch percentage, and construction pattern is fundamental to successful lingerie design, with heavier power meshes (70-120 gsm) providing structure and support while lighter meshes (30-50 gsm) and tulles create ethereal transparency and layering effects.

As a manufacturer with over 13 years in the intimate apparel industry, I've witnessed countless lingerie collections transformed by mastering the art of mesh and tulle application. The difference between ordinary and extraordinary often comes down to understanding the nuanced properties of these versatile fabrics and how to leverage them effectively in design.

How Do Different Mesh Weights Impact Support and Structure in Lingerie?

Selecting mesh by weight without understanding its performance characteristics leads to design failures. Too light, and the garment lacks support; too heavy, and it loses the delicate allure that makes lingerie special.

Mesh weights directly correlate with support capabilities: heavyweight power meshes (90-120 gsm) provide firm compression and structure for shapewear and support panels, medium-weight meshes (60-80 gsm) offer moderate support with better drape for body-contouring pieces, while lightweight meshes (30-50 gsm) create gentle shaping with maximum visual delicacy.

In my experience at HAVING, the weight of mesh fabric is the foundation of successful lingerie engineering. We categorize our meshes into distinct performance tiers to help designers make informed choices:

Heavyweight power meshes (90-120 gsm) provide the maximum structure and compression. These robust fabrics feature minimal stretch in one direction and moderate stretch in the perpendicular direction, creating firm control. We typically use these in shapewear panels, high-support bra wings, and structured bodysuit panels where compression and stability are essential.

Medium-weight meshes (60-80 gsm) strike a balance between support and visual lightness. With approximately 30-40% four-way stretch, these versatile meshes work wonderfully in bra bands, side panels, and supportive yet comfortable underwear. They maintain shape while allowing natural movement, making them perfect for everyday lingerie that requires reliable support without feeling restrictive.

Lightweight meshes (30-50 gsm) offer gentle support with maximum visual delicacy. With stretch capacity ranging from 40-60%, these meshes create a barely-there sensation while still providing light structure. We use these for decorative overlays, sheer panels, and delicate design details where aesthetic considerations are paramount.

Understanding the relationship between mesh weight and performance has allowed us to engineer pieces like our bestselling shaping briefs, which use strategic panels of varying mesh weights to create targeted compression in areas that need control while maintaining comfort and visual lightness elsewhere.

What Role Does Stretch Percentage Play in Creating Comfortable Yet Supportive Mesh Lingerie?

Many designers select mesh based solely on appearance, overlooking stretch percentages—the crucial factor that determines whether a garment will provide support without restricting movement or creating pressure points.

Stretch percentage in mesh fabrics determines both support and comfort: low-stretch meshes (10-20%) create firm structure but can restrict movement if improperly placed, medium-stretch meshes (30-50%) balance support with flexibility for everyday wear, while high-stretch meshes (60%+) prioritize comfort and body-hugging fit over structural support.

At HAVING, we've developed a comprehensive testing protocol for all our mesh fabrics that goes beyond basic stretch measurement. We analyze how each mesh performs under different types of body movement and strain patterns.

Low-stretch meshes (10-20% stretch) are direction-specific, typically stretching primarily in one direction. This controlled elasticity makes them excellent for areas requiring firm support with minimal expansion, such as underbust bands, shapewear panels targeting the abdomen, and structured bodysuits. The limited stretch creates the architecture of the garment, preventing unwanted movement or expansion.

Medium-stretch meshes (30-50% stretch) offer balanced flexibility that accommodates natural body movement while maintaining shape. These four-way stretch fabrics work exceptionally well in full-coverage bra cups, side panels, and everyday underwear where comfort is as important as support. They move with the body rather than constraining it.

High-stretch meshes (60%+ stretch) prioritize comfort and adaptability. These ultra-flexible fabrics conform beautifully to body contours and accommodate significant movement without creating pressure points. We use these in comfort bands, lingerie designed for sleep or loungewear, and in decorative panels where visual effect is more important than structural support.

One of our most successful applications combines different stretch zones within a single garment. For example, our wireless bralettes use lower-stretch mesh in underbust areas for lift and support, medium-stretch in the cups for shape maintenance, and higher-stretch mesh at the back and sides to ensure comfort during movement. This strategic approach to stretch percentage creates garments that feel custom-fitted.

How Can Pattern Selection in Mesh Create Visual Interest Without Sacrificing Function?

Plain mesh is often the default choice, but this overlooks how pattern selection can dramatically enhance both aesthetic appeal and functional performance in lingerie design.

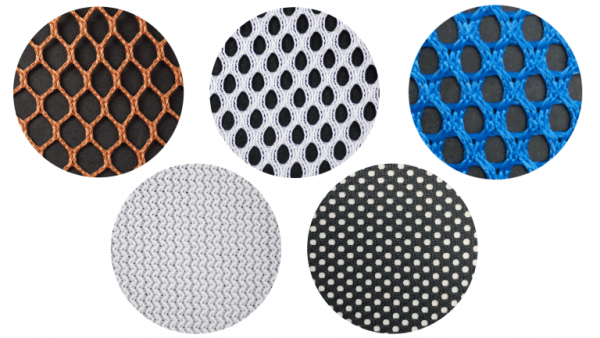

Mesh pattern selection affects both aesthetics and functionality: diamond patterns provide directional strength for targeted support, hexagonal patterns distribute tension more evenly for all-over control, while geometric patterns can create visual interest while providing specific stretch characteristics aligned with body movement.

The pattern within mesh fabric isn't just decorative—it's a functional engineering choice that impacts performance. At HAVING, we've developed an extensive library of mesh patterns, each with unique performance characteristics:

Diamond-pattern meshes create greater strength along their diagonal lines, making them ideal for directional support. We frequently use diamond patterns in shapewear panels and bra wings where we want to control stretch in specific directions. The beauty of diamond patterns is that they can be oriented to align with or counter natural body movement, depending on the design goals.

Hexagonal meshes distribute tension more evenly in multiple directions, creating smooth, consistent compression. These patterns work exceptionally well in all-over shaping garments and smoothing panels. The six-sided structure creates a more balanced distribution of force than diamond patterns, resulting in a smoother silhouette without pressure points.

Geometric pattern meshes combine aesthetic appeal with functional engineering. By varying the density and direction of the pattern, we can create visual interest while controlling where the fabric offers more or less support. These patterns are particularly effective in creating visual slimming effects by strategically placing denser patterns in areas where compression is desired.

One of our most innovative approaches involves graduated patterns, where the mesh structure transitions from denser to more open across a single panel. This creates varying levels of support and compression within one seamless piece, allowing for targeted shaping without visible seam lines—a technique we've used successfully in our high-end shapewear collections.

What's The Secret to Layering Mesh and Tulle for Visual Depth?

Many designers use single layers of mesh or tulle, missing opportunities to create visual depth and textural complexity that elevate designs from basic to breathtaking.

Strategic layering of mesh and tulle creates dimension through contrast: pairing different densities creates moiré effects, overlaying contrasting patterns creates dynamic visual texture, while combining meshes of different stretch percentages creates targeted functional zones within a visually seamless design.

Layering different meshes is both an art and a science that we've refined over years of experimentation at HAVING. The visual magic happens when we play with contrast between layers:

Density contrast creates depth through varying degrees of opacity. By layering a fine-hole mesh over a medium-hole mesh, we create subtle moiré effects that shift with movement and light. This technique adds visual interest without bulk and has become a signature element in our premium lingerie collections where subtle sophistication is key.

Pattern contrast emerges when overlaying meshes with different structural patterns. For instance, placing a diagonal-patterned mesh over a honeycomb structure creates complex visual geometry that adds dimension while maintaining the lightweight feel essential to luxury lingerie. We've found this particularly effective in bodysuits and bralettes where large expanses of mesh benefit from added visual texture.

Color layering creates depth through subtle tinting. By layering flesh-toned mesh beneath colored tulle, or vice versa, we create complex color dimensions that appear to change with movement and lighting. This technique allows for richer, more nuanced coloration than single-layer applications and creates the illusion of color that emerges from within the fabric rather than sitting on its surface.

Functional layering combines different performance characteristics in a visually seamless way. By sandwiching a lower-stretch mesh between layers of higher-stretch mesh, we create targeted support zones without visible seams or panels. This innovative approach allows us to engineer precise functionality while maintaining a clean, minimalist aesthetic—a technique we've successfully employed in our seamless shapewear collection.

How Do Different Tulle Types Create Distinct Aesthetic Effects?

Many lingerie lines rely on basic nylon tulle, missing the opportunity to explore how different tulle varieties can create distinctive aesthetics from vintage romance to modern minimalism.

Tulle variety significantly impacts visual aesthetics: fine point d'esprit adds delicate texture and vintage charm, Italian tulle creates smooth modern minimalism, cotton tulle offers organic softness with a matte finish, while metallic-infused tulles provide contemporary glamour with subtle light-catching properties.

Through our work with luxury lingerie brands, HAVING has developed expertise in leveraging different tulle varieties to create specific aesthetic narratives:

Point d'esprit tulle features tiny dots or geometric patterns woven into fine mesh, creating delicate texture that evokes vintage elegance. We often use this in romantic collections inspired by traditional lingerie construction, where the subtle pattern adds dimension without overwhelming delicate designs. The raised dots catch light beautifully and create tactile interest that enriches the wearing experience.

Italian tulle, with its exceptionally smooth, fine construction, creates clean lines and modern minimalism. This ultra-fine tulle creates an almost invisible sheer effect that works particularly well in contemporary designs where the focus is on clean lines and subtle transparency. Its exceptional drape allows it to follow body contours perfectly, making it ideal for modern, minimalist designs that celebrate natural body shapes.

Cotton tulle offers a distinctly different aesthetic with its slightly textured, matte appearance. This natural-fiber tulle creates an organic, soft visual effect quite different from the sleeker look of synthetic tulles. We've found it particularly effective in eco-conscious collections where the natural texture and biodegradable composition align with sustainability values while offering a uniquely soft aesthetic.

Metallic-infused tulles incorporate subtle metallic threads or finishes that catch light without appearing overtly glittery. These specialized tulles add contemporary glamour and create dynamic visual effects that shift with movement and lighting conditions. The metallic elements can be aligned with the tulle structure or deliberately misaligned to create interesting moiré patterns that add visual complexity.

One of our most successful applications has been combining different tulle types within a single garment—perhaps using Italian tulle for clean, sleek panels while incorporating point d'esprit in strategically placed overlays to add textural interest to key areas. This considered approach to tulle selection helps elevate designs from basic to sophisticated with subtle material contrasts.

How Can Edge Finishing Techniques Enhance Mesh and Tulle Designs?

Raw edges can undermine otherwise excellent mesh lingerie designs, creating durability issues and comfort problems that impact consumer satisfaction and product longevity.

Edge finishing dramatically impacts both aesthetics and function: fine elastics create clean, minimal lines and gentle support, scalloped edges add decorative interest without bulk, while bound edges provide more definitive structure and can incorporate contrasting colors or textures for design emphasis.

At HAVING, we view edge finishing as the crucial final element that can either elevate or undermine a mesh or tulle design. Our technical expertise includes numerous specialized techniques:

Ultrasonic cutting creates clean, precisely finished edges without additional materials. This advanced technology uses high-frequency vibrations to simultaneously cut and seal synthetic meshes, creating nearly invisible edges that lie flat against the skin. This technique works beautifully for minimalist designs where visible elastic or binding would detract from the clean aesthetic.

Heat-sealed picot edges combine delicate decorative detail with practical edge stability. This technique applies a thin elastic with a small picot (scalloped) edge that's heat-bonded to the mesh, creating a secure finish with minimal bulk. The tiny scallops add a subtle feminine detail that frames the body beautifully without creating visible lines under clothing.

Enclosed binding offers maximum durability and can become a design feature in its own right. By encasing the mesh edge in fabric binding, we create a strong, defined edge that won't roll or stretch out over time. This technique works particularly well for supportive garments and can incorporate contrasting colors or textures that become part of the design aesthetic.

Seamless bonding creates invisible transitions between mesh and solid fabrics. This advanced technique uses heat-activated adhesives to create stable, bulk-free joins between different materials. The result is a smooth transition that eliminates the need for visible stitching and creates a modern, technical aesthetic perfect for contemporary lingerie designs.

Our most innovative approach combines multiple edge treatments within a single garment—perhaps using invisible ultrasonically cut edges in areas where minimalism is desired, while incorporating decorative picot or binding in areas where visual interest or additional support benefits the design. This thoughtful approach to edge finishing ensures both beauty and functionality.

Conclusion

Mastering mesh and tulle selection transforms ordinary lingerie into extraordinary pieces that balance visual delicacy with technical performance. By understanding how weight, stretch, pattern, and finishing techniques interact, designers can create garments that flatter the body, provide appropriate support, and deliver breathtaking visual impact. The difference is in these details—where art meets engineering in the intimate world of lingerie design.

Get a Free Quote for Your Underwear Projects