The #1 Reason for Lingerie Returns: How to Master Sizing & Grading with Your Manufacturer?

Your brand is bleeding money and customer trust with every returned package. You've perfected the design and used the best materials, but the customer reviews all say the same thing: "It doesn't fit."

The number one reason for lingerie returns is inconsistent and inaccurate sizing. This problem is solved by mastering two critical, interconnected stages: creating a perfect base size with a professional fit model, and then applying precise "grade rules" to scale that fit correctly across your entire size range.

Nothing kills a new lingerie brand faster than a reputation for poor fit. It’s a cash-burning, confidence-destroying problem. As a manufacturer, I've seen brands obsess over the color of a bow but completely overlook the mathematics of their size chart. They don't realize that a perfect Medium sample means nothing if the Extra Large is unwearable. At HAVING (China) Ltd., our "body-before-fabric" philosophy is a commitment to fit. We know that a garment only succeeds if it fits the human body flawlessly. This guide will walk you through the professional process to master sizing and stop the flood of returns.

Step 1: Are You Nailing the "Golden Sample"?

You have a vision for your core size, typically a Medium or a 34B. You create a sample, try it on yourself or a friend, and decide it's "good enough." This is the first and most fundamental mistake.

Before you can think about a size range, you must perfect one single "base size" or "golden sample." This requires working with a professional fit model whose measurements perfectly match your target customer for that specific size. This sample is the foundation for your entire collection.

A fit model is not the same as a runway model or a friend who is "about a size Medium." A professional fit model has precise, known measurements and, most importantly, has the vocabulary to provide technical feedback like "the underwire is digging in at the side" or "the band is riding up in the back." I've been in countless fit sessions. The feedback from a professional model is invaluable. They are a living, breathing blueprint. We once spent three rounds of revisions on a new T-shirt bra, adjusting the cup apex by just a few millimeters each time based on the fit model's feedback. The final result was a perfect, seamless fit that became a bestseller. Investing in this stage saves you a fortune later.

Creating Your Perfect Base Size

This is a non-negotiable process for any serious brand.

- Define Your Target Customer: First, who is your ideal customer for your base size? What are her exact measurements? For a 34B, this means defining the underbust and overbust circumference precisely.

- Hire a Professional: Use a modeling agency to find a fit model who matches these exact measurements. Don't compromise.

- The Fit Session: During the session, you and your technical designer (or your manufacturer's team) assess the sample on the model. You check every aspect: band, cups, straps, gore (the center part).

- Iterate Until Perfect: Based on the feedback, you create a new sample. You repeat the process until the fit is absolutely flawless. This final, approved sample becomes your "golden sample."

Step 2: Are You Just "Adding Inches" to Your Sizes?

You have a perfect Medium sample. Now you need to create the Small, Large, and Extra Large. You assume you can just subtract an inch for the Small and add an inch for the Large to every measurement. This is a catastrophic mistake.

"Grading" is the technical process of creating your other sizes, and it is not linear. A human body does not scale up or down uniformly. You must use a set of sophisticated "grade rules" to account for the fact that as a body gets larger, it gains dimension differently in different places.

This is where many brands fail spectacularly without realizing it. For example, when grading from a 34B to a 38D, you don't just make everything bigger. The underwire needs to change shape, the cup needs more depth and projection, the straps need to be wider to offer more support, and the hook-and-eye closure needs to be wider (e.g., a 3-hook instead of a 2-hook). A factory that just "adds inches" will produce an XL that offers no support and fits terribly. Our technical team at HAVING are experts in lingerie grading. We understand the complex relationship between band and cup sizes, ensuring that the perfect fit of your golden sample is translated faithfully to every single size you sell, whether it's a simple panty or a complex piece of shapewear.

The Basics of Grade Rules

Grade rules are the mathematical formulas that grow or shrink your base pattern.

| Garment Part | Linear Grading (Wrong) | Proportional Grading (Correct) |

|---|---|---|

| **Bra Band** | Add 2 inches for each band size up. | Add 2 inches to the band, but also slightly increase the wing height and hook-and-eye width. |

| **Bra Cup** | Add 1 inch to the cup width/height for each cup size up. | Increase volume, projection, and wire shape. The whole geometry changes, not just the size. |

| **Straps** | Keep strap width the same for all sizes. | Increase strap width for larger cup sizes (e.g., from 12mm to 18mm) to provide adequate support. |

Step 3: Is Your Tech Pack Speaking a Clear Language?

You've done the hard work of fitting and grading. Now you need to communicate this crucial information to your manufacturer, who may be thousands of miles away. How do you ensure they execute your vision perfectly?

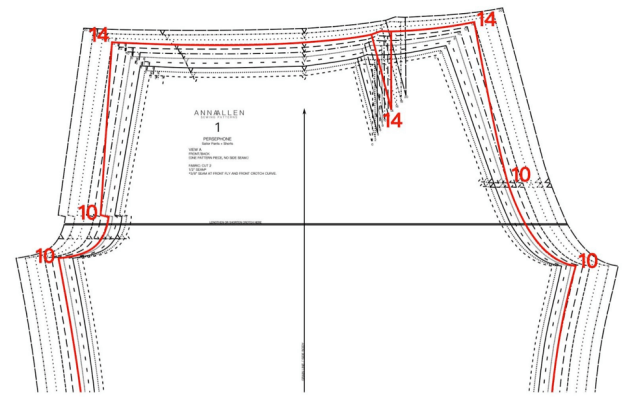

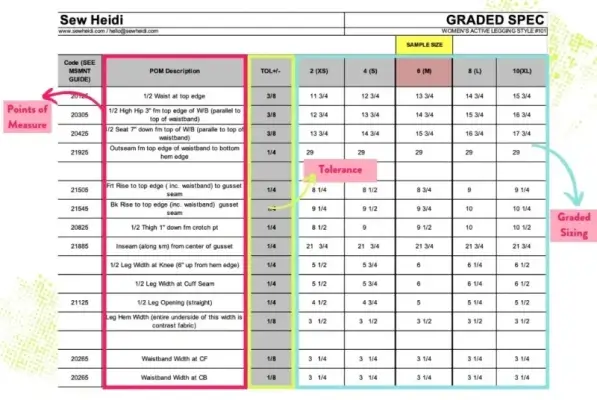

Your tech pack must contain a final, approved "Graded Size Specification" sheet. This document is the ultimate source of truth. It must list every key point of measure (POM) for every size in your range, along with an acceptable tolerance (e.g., +/- 1cm).

This document prevents any ambiguity. It becomes part of the contract between you and your manufacturer. During the final quality control inspection, this is the exact sheet the inspector will use to check the measurements of the bulk production. A vague instruction like "grade up for L and XL" is useless. You must provide the exact final measurements you expect. As part of our comprehensive OEM/ODM process, we work with our clients to finalize this spec sheet before any bulk cutting begins. It protects both the brand and the manufacturer and ensures everyone is working towards the same goal: a consistently fitting product.

Key Elements of a Graded Spec Sheet

This is the document your QC inspector will use.

- Points of Measure (POM): A list of all the critical measurements to be checked. For a panty, this might be "1/2 Waistband (Relaxed)," "1/2 Hip," and "Front Rise."

- Size Columns: A separate column for every size you are producing (XS, S, M, L, XL, etc.).

- The Measurements: The precise measurement (in cm or inches) for each POM for each size.

- Tolerance: A crucial column that states the acceptable variance from the spec. For example, if the Medium waist is 35cm with a +/- 1cm tolerance, any garment measuring between 34cm and 36cm is acceptable. Anything outside that range is a defect.

Conclusion

Mastering sizing isn't a dark art; it's a disciplined process. By perfecting your base size, applying correct grade rules, and communicating clearly through your tech pack, you can conquer the #1 cause of returns.

Frequently Asked Questions (FAQ)

1. How many sizes should I launch with?

It's wise to start with a focused range. A common approach is to launch with 4-5 core sizes (e.g., S, M, L, XL) that cover the heart of the market. For bras, you might start with a more limited matrix, like 32-36 bands and B-D cups, before expanding.

2. What is "vanity sizing"?

Vanity sizing is the practice of labeling clothes with sizes smaller than their actual measurements to make consumers feel better. While some brands do this, it can cause major confusion and lead to returns if a customer who is a "Medium" in every other brand is a "Small" in yours. It's generally better to stick to standardized measurements.

3. Do I need a different fit model for my plus-size range?

Yes, absolutely. A plus-size body has different proportions and support needs. To create an authentic and well-fitting plus-size range, you must work with a professional plus-size fit model (e.g., someone who is a perfect 38DD or 1X) to create a separate "golden sample" for that range.

4. What is an acceptable tolerance for lingerie measurements?

For stretchy knit garments like lingerie, a typical tolerance is between +/- 0.5 cm to +/- 1.5 cm, depending on the point of measure. The waistband on a panty might have a 1 cm tolerance, while a smaller detail like strap width might have a much tighter tolerance. This should be agreed upon with your manufacturer.