Sports Underwear Manufacturing: A Guide to Breathability and Comfort?

Pain points plague athletes and fitness enthusiasts when wearing standard underwear during physical activities. Chafing, excessive sweating, and discomfort can ruin even the most motivated workout session.

Sports underwear differs from regular underwear primarily through specialized moisture-wicking fabrics, strategic ventilation, anatomical support, and seamless construction that prevents chafing while allowing full range of motion during physical activities.

At HAVING, we understand the critical role that proper sports underwear plays in athletic performance. As a leading fashion lingerie manufacturer with over 30 million USD in annual sales across 3000+ stores, we've perfected the art of creating sports underwear that prioritizes both function and comfort.

What Makes Sports Underwear Different from Regular Underwear?

Pain points like chafing, excessive moisture, and restricted movement plague athletes wearing standard underwear during workouts. These issues can significantly impact performance and enjoyment.

Sports underwear is specifically engineered with moisture-wicking fabrics, strategic ventilation zones, anatomical support, and seamless construction to prevent discomfort during physical activities. Unlike regular underwear, sports underwear prioritizes breathability, quick-drying properties, and freedom of movement.

When I first started developing sports underwear at HAVING, I noticed many athletes were simply wearing their regular underwear for workouts, unaware of how much it was hindering their performance. The difference in materials alone makes a tremendous impact - while cotton absorbs and retains moisture, technical fabrics used in sports underwear actively pull sweat away from the skin.

Our sports underwear development process involves extensive testing with athletes across different sports to ensure optimal performance. We analyze movement patterns, sweat zones, and pressure points to create designs that work with the body rather than against it. This body-before-fabric philosophy has been central to our approach at HAVING, allowing us to create products that truly enhance athletic performance.

How to Choose the Best Fabrics for Breathable Sports Underwear?

Pain points in fabric selection can lead to uncomfortable sports underwear that causes irritation, retains moisture, or fails to provide adequate support during intense activities.

The most breathable fabrics for sports underwear include synthetic blends like polyester/spandex, nylon/elastane, and natural options like bamboo and modal. These materials offer superior moisture-wicking, quick-drying properties, and stretch recovery essential for athletic performance.

At HAVING, our fabric selection process is rigorous and science-driven. We've tested countless material combinations to find the perfect balance between breathability, durability, and comfort. Let me share our findings on the top fabric choices for sports underwear:

Comparison of Top Fabrics for Sports Underwear

| Fabric Type | Breathability Rating | Moisture-Wicking | Durability | Best For |

|---|---|---|---|---|

| Polyester/Spandex | High | Excellent | Very High | High-intensity workouts |

| Nylon/Elastane | Medium-High | Very Good | High | Endurance activities |

| Bamboo | Very High | Good | Medium | Sensitive skin, yoga |

| Modal | High | Good | Medium-High | Everyday athletic wear |

| Microfiber | Medium | Excellent | High | Compression needs |

I've personally overseen the development of our signature fabric blend at HAVING, which combines the moisture-wicking properties of polyester with the stretch of spandex and the softness of modal. This proprietary blend has become the foundation of our most popular sports underwear lines, offering superior performance across various activities.

We've also invested in eco-friendly fabric options, including recycled polyester and organic bamboo, to meet the growing demand for sustainable athletic wear. Our eco-friendly underwear collection maintains the same high performance standards while reducing environmental impact.

What Design Features Enhance Breathability in Sports Underwear?

Pain points in poorly designed sports underwear include inadequate ventilation, restrictive fit, and uncomfortable seams that cause friction during movement.

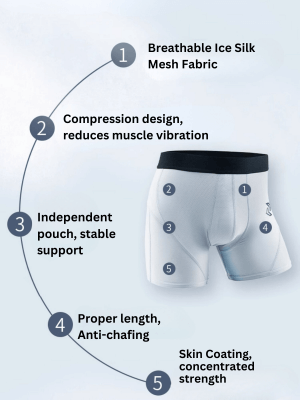

Key design features that enhance breathability include strategically placed mesh panels, perforated fabrics in high-heat zones, minimal seam construction, and anatomical cuts that follow the body's natural contours while providing adequate support.

At HAVING, our design process begins with understanding the human body in motion. I work closely with our design team to map heat zones and friction points during different types of physical activities. This research informs our placement of ventilation features and support structures.

Critical Design Elements for Breathable Sports Underwear

Ventilation Zones

We incorporate mesh panels or perforated fabrics in areas that generate the most heat and sweat, typically the lower back, between the legs, and along the waistband. These strategic zones allow for maximum air circulation without compromising support.

Seamless Construction

Our advanced seamless technology eliminates chafing by reducing or removing seams in critical areas. When seams are necessary, we use flat-lock stitching that lies flat against the skin to prevent irritation during repetitive movements.

Anatomical Support

For men's sports underwear, we design pouches that provide support without compression, allowing for natural movement while preventing friction. For women's sports underwear, we focus on creating comfortable waistbands and leg openings that don't dig in or ride up during activity.

Moisture-Wicking Waistbands

Our waistbands are engineered to wick away sweat quickly and dry rapidly, preventing the uncomfortable feeling of a damp waistband during workouts. We use a combination of elastic materials that maintain their shape even after repeated washing.

I remember working with a professional marathon runner who complained about persistent chafing despite trying various brands of sports underwear. After analyzing his running form and sweat patterns, we developed a custom design with targeted ventilation and support. The result was a breakthrough product that eventually became one of our bestselling items in our men's underwear collection.

How Does Manufacturing Technology Impact Sports Underwear Performance?

Pain points in manufacturing include inconsistent quality, poor durability, and inability to achieve the technical features needed for high-performance sports underwear.

Advanced manufacturing technologies like seamless knitting, heat bonding, laser cutting, and silicone application significantly enhance sports underwear performance by eliminating seams, creating targeted compression zones, and improving overall comfort and durability.

At HAVING, we've invested heavily in cutting-edge manufacturing equipment to stay at the forefront of sports underwear innovation. Our factory in Shantou City, Guangdong Province, houses some of the most advanced textile machinery available today.

Key Manufacturing Technologies We Employ:

Seamless Knitting Machines

These specialized machines create entire garments without seams, dramatically reducing friction points and enhancing comfort. Our seamless technology allows us to vary the density and elasticity of different zones within the same garment, providing targeted support where needed.

Heat Bonding Technology

Instead of traditional stitching, heat bonding fuses fabric layers together, creating smooth, flat connections that won't irritate the skin. This technology is particularly valuable for creating supportive structures without adding bulk or seams.

Laser Cutting

Precision laser cutting allows us to create clean, sealed edges that won't fray or irritate. This technology enables intricate ventilation patterns and custom fits that would be impossible with traditional cutting methods.

Silicone Application

We use silicone printing technology to create grip zones that prevent riding up during intense movement. This is particularly important for sports underwear worn during high-impact activities like running or HIIT workouts.

I recently led a project to upgrade our manufacturing capabilities with new seamless knitting machines that can produce garments with variable compression zones. This investment has allowed us to create sports underwear with targeted support for specific muscle groups, enhancing both comfort and performance for athletes.

Our commitment to manufacturing excellence extends to our quality control processes. Each piece of sports underwear undergoes rigorous testing for stretch recovery, moisture-wicking efficiency, and durability before leaving our factory. This attention to detail ensures that our women's underwear products maintain their performance properties even after repeated use and washing.

How to Test and Ensure Quality in Sports Underwear Production?

Pain points in quality control include inconsistent sizing, premature fabric degradation, and failure of technical features after washing or extended use.

Effective quality testing for sports underwear includes wicking rate measurement, stretch recovery testing, wash durability assessment, and real-world performance trials with athletes. These tests ensure the final product maintains its technical properties throughout its lifecycle.

Quality control is non-negotiable at HAVING. Our comprehensive testing protocol ensures that every batch of sports underwear meets our exacting standards before reaching customers. Here's a glimpse into our quality assurance process:

Our Quality Testing Protocol

| Test Type | Purpose | Method |

|---|---|---|

| Moisture Management | Measure wicking efficiency | Vertical wicking test, MMT testing |

| Stretch Recovery | Ensure garment returns to original shape | Cyclic loading test, elasticity measurement |

| Wash Durability | Verify performance after multiple washes | Accelerated wash testing (50+ cycles) |

| Colorfastness | Ensure colors don't bleed or fade | Crocking test, perspiration resistance |

| Comfort Assessment | Evaluate real-world comfort | Wear trials with athletes, feedback analysis |

Beyond laboratory testing, we conduct extensive wear trials with athletes across different sports. This real-world feedback is invaluable for identifying issues that might not appear in controlled testing environments. I personally review all feedback from these trials and work with our development team to make necessary adjustments.

We also maintain strict quality control during production, with inspections at multiple stages of the manufacturing process. Our quality control team randomly selects samples from each production run for comprehensive testing, ensuring consistency across all products.

This commitment to quality has earned HAVING a reputation for reliability among our retail partners. Our return rate for sports underwear is consistently below industry averages, reflecting the durability and performance of our products.

What Are the Future Trends in Sports Underwear Manufacturing?

Pain points in the evolving sports underwear market include keeping up with consumer expectations for sustainability, smart features, and personalization.

Emerging trends in sports underwear manufacturing include biodegradable fabrics, temperature-regulating technologies, antimicrobial treatments, 3D-knitted custom fits, and smart textiles that monitor biometric data during workouts.

At HAVING, we're constantly researching and developing new technologies to stay ahead of industry trends. Our innovation team works closely with material scientists, textile engineers, and professional athletes to identify opportunities for advancement in sports underwear design and manufacturing.

Key Trends We're Exploring:

Sustainable Materials

We're expanding our use of recycled and biodegradable materials without compromising performance. Our research into bio-based elastane alternatives shows promising results for reducing petroleum dependence in stretch fabrics.

Smart Textiles

We're developing prototypes with embedded sensors that can monitor muscle fatigue, hydration levels, and body temperature during workouts. These insights can help athletes optimize their training and recovery.

3D Knitting for Custom Fit

Our newest manufacturing equipment allows for made-to-measure sports underwear based on individual body scans. This technology enables truly personalized fit without the traditional costs associated with custom garments.

Thermoregulation Technology

We're testing phase-change materials that absorb or release heat depending on body temperature, helping athletes maintain optimal performance in varying conditions.

Odor Control Innovations

Beyond traditional antimicrobial treatments, we're exploring natural mineral-based solutions that permanently prevent odor-causing bacteria without washing out over time.

I recently attended a textile innovation conference where I connected with researchers developing biodegradable elastane alternatives. We're now testing these materials in our sports bra prototypes, with promising early results for both performance and environmental impact.

Our commitment to innovation extends to our manufacturing processes as well. We're implementing digital production management systems that reduce waste, improve efficiency, and allow for greater customization options for our brand partners.

Conclusion

Sports underwear manufacturing requires a delicate balance of technical expertise, material science, and human-centered design. By focusing on breathability, comfort, and performance, manufacturers can create products that truly enhance athletic experiences.

Get a Free Quote for Your Sports Underwear Projects

Frequently Asked Questions (FAQ)

What is the best material for sports underwear?

The best material for sports underwear depends on the activity, but typically blends of polyester, nylon, spandex, and elastane offer excellent moisture-wicking, breathability, and stretch recovery. Natural options like bamboo and modal provide softness and breathability but may not dry as quickly as synthetic materials.

How often should sports underwear be replaced?

Sports underwear should typically be replaced every 6-12 months with regular use, or when you notice the elastic losing its recovery, the fabric becoming thin, or the moisture-wicking properties diminishing. High-quality sports underwear like those manufactured by HAVING tend to last longer due to superior materials and construction.

Can sports underwear help prevent chafing?

Yes, properly designed sports underwear can significantly reduce chafing by using seamless construction, flat-lock stitching, and moisture-wicking fabrics that keep skin dry. Strategic placement of seams away from high-friction areas also helps prevent irritation during movement.

Is compression beneficial in sports underwear?

Moderate compression in sports underwear can provide muscle support, reduce vibration, and improve blood circulation during activity. However, the level of compression should be comfortable and not restrictive. Different sports may benefit from varying levels of compression in specific areas.

How should sports underwear be washed to maintain performance?

For best results, wash sports underwear in cold water on a gentle cycle with mild detergent. Avoid fabric softeners, which can clog the moisture-wicking fibers. Air drying is preferable to machine drying, as high heat can damage elastic fibers and reduce the lifespan of the garment.