Sourcing Lingerie from China? 7 Myths vs. Realities for 2026

You're considering China for your lingerie production, drawn by its legendary manufacturing power. But you're held back by outdated stories of poor quality, communication barriers, and intellectual property theft you've heard from others.

Sourcing lingerie from China in 2026 is a world away from the stereotypes of the past. While challenges exist, the reality is a highly advanced, quality-focused, and innovative ecosystem. The key is to understand the difference between old myths and the modern reality to find a truly strategic partner.

For over two decades, I've been on the factory floor here in Shantou, the heart of China's lingerie industry. I've seen the incredible transformation firsthand. The old narratives are persistent, but they no longer reflect the dynamic and sophisticated supply chain that exists today. Many first-time brand owners approach us at HAVING (China) Ltd. with these outdated fears, and a huge part of my job is showing them the reality. This guide will debunk the seven most common myths I hear, giving you the confidence to navigate the world's most powerful manufacturing hub.

Myth #1: Is It True That 'Made in China' Means Low Quality?

This is the oldest myth, the one that makes brands hesitate the most. They picture crowded, low-tech workshops churning out cheap, disposable goods, and worry their premium brand will be compromised.

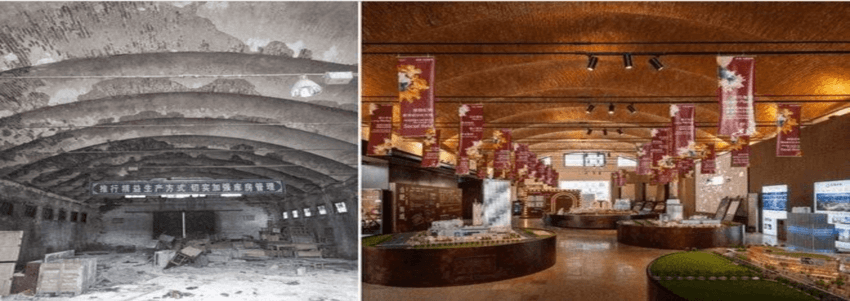

This is perhaps the most outdated myth of all. Today, China is home to some of the world's most technologically advanced factories, producing luxury goods for top global brands. Quality is no longer about the country; it's about the specific factory partner you choose and the price point you are willing to pay for.

Think about the phone in your pocket or the high-end electronics in your home; they were most likely made in China with incredible precision. The same evolution has happened in apparel. I've walked clients through our clean, modern facility, showing them our computer-guided cutting machines and the specialized sewing equipment we use for delicate bras and panties. They are always amazed. The reality is, China's manufacturing ecosystem is vast. It can produce $2 fast-fashion items, and it can produce $200 luxury couture pieces. You get what you pay for. A low-quality product is not a "China problem"; it's the result of choosing a low-quality factory or providing a low-quality budget. A great partner will refuse to make a poor-quality product because their reputation is on the line, just as much as yours is.

Reality: You Set the Quality Standard

The modern Chinese supply chain is a tool. The quality of the output depends entirely on the instructions you provide and the partner you select.

| The Old Myth | The 2026 Reality |

|---|---|

| All Chinese factories are low-tech and produce cheap goods. | China has a tiered system, from basic workshops to state-of-the-art smart factories that service the world's top luxury brands. |

| Quality is inherently poor and inconsistent. | Quality is a direct result of your budget, your tech pack's detail, your QC process, and your factory's specialization. |

| The focus is only on speed and low cost. | Leading manufacturers now compete on technology, sustainability (GRS/OCS certifications), and craftsmanship to win high-value clients. |

Myth #2: Is It Impossible to Communicate Effectively?

You've heard stories of emails getting lost in translation, of simple instructions being misunderstood, leading to disastrous production errors. You're worried a language barrier will make the entire process a constant struggle.

While language differences are real, professional, export-focused manufacturers have invested heavily in skilled, English-speaking merchandising and sales teams. Today, communication breakdowns are more often caused by a lack of clarity in technical documents (like the tech pack) than by language itself.

This fear is understandable, but the reality of global trade in 2026 is seamless connectivity. Our team uses email, WhatsApp, and video calls daily to communicate with clients from New York to London. The key to clarity isn't perfect grammar; it's having a single source of truth. This is why we stress the importance of a detailed tech pack. That document, with its clear diagrams, measurements, and specifications, transcends language. When a client points to section 5.2 of a tech pack and says "change stitch type to zig-zag," the instruction is unambiguous for our production team. Poor communication is less about language and more about a lack of professional process. A good partner will have systems in place to ensure nothing is lost in translation.

Reality: Clarity Comes from Process, Not Just Language

Effective communication is a two-way street built on professional tools and processes.

- Dedicated Merchandisers: Professional factories assign you a dedicated, English-speaking merchandiser who is your single point of contact. They are trained to translate your brand's vision into technical instructions for the factory floor.

- Visual Communication: A picture is worth a thousand words. We rely on detailed flat sketches, reference photos, and video calls to confirm complex details visually.

- The Tech Pack as a Universal Language: A well-made tech pack with universal codes for stitches, seams, and components is understood by apparel professionals worldwide.

- Confirmation Samples: Before any bulk production, a final pre-production sample is sent to you for approval. This physical sample is the ultimate confirmation that all communications have been understood correctly.

Myth #3: Will My Designs Be Stolen?

This is a huge fear for any designer. You send your unique, innovative designs to a factory in China, and a month later you see cheap knock-offs of your product for sale online.

While IP theft can happen, the risk is dramatically overstated, especially when dealing with reputable, established manufacturers. Professional factories value their long-term relationships with brands and their own reputation far more than the short-term gain of stealing a single design. Protecting your IP starts with choosing the right partner.

Think about it from our perspective as a manufacturer. Our business, which supports over 3000 stores, is built on trust. If we were known for stealing designs, global brands would stop working with us immediately. Our entire business model would collapse. It makes zero business sense. The horror stories you hear often come from brands that worked with shady, unknown trading companies or very low-end factories found on open sourcing platforms, not established manufacturing partners. The best way to protect yourself is to work with a partner who has a long-standing reputation to uphold. Furthermore, for highly sensitive projects, we are always willing to sign legally binding agreements like an NNN (Non-Disclosure, Non-Use, Non-Circumvention) agreement that is enforceable in China.

Reality: Your Best Protection is a Good Partner

Proactive steps and choosing the right partner are your strongest defenses against IP theft.

| The Old Myth | The 2026 Reality |

|---|---|

| All Chinese factories will steal your designs. | Reputable factories have too much to lose. Their business depends on long-term partnerships and trust. |

| There is no legal protection for your IP. | You can and should use a China-specific NNN agreement. It is also wise to register your trademark in China as a defensive measure. |

| The risk is unavoidable. | The risk is highest with untraceable middlemen or low-end factories. Thoroughly vetting your partner is the single most effective way to minimize risk. |

Myth #4: Is China Always the Cheapest Option?

For decades, "Made in China" was synonymous with "low cost." Many brands assume that China is automatically the cheapest place to produce, no matter the product.

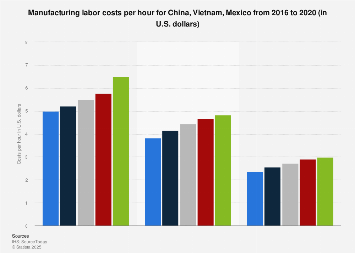

While China remains incredibly cost-competitive due to its massive scale and efficiency, it is no longer the "cheapest" for every product. For very simple, labor-intensive items, countries like Vietnam or Bangladesh might offer lower labor costs. China's advantage today lies in its "best total value" for complex products that require skilled labor, advanced technology, and a deep supply chain.

This is a crucial point for brands to understand in 2026. Labor costs in China have risen. If your product is a very simple cotton panty with minimal sewing, you may find a lower per-unit cost in another country. However, for a complex product like our high-performance shapewear or a multi-part underwire bra, China's value is unbeatable. Why? Because we have everything here. The specialized elastic supplier is in the next town over. The factory that makes advanced hook-and-eye closures is a one-hour drive away. This supply chain "cluster" creates incredible speed and efficiency that other countries can't match. You might save $0.10 on labor elsewhere but lose weeks in shipping delays waiting for a specific trim to be imported. You must consider the total "landed cost" and speed to market, not just the labor price.

Myth #5: Are the Factories Unethical and Environmentally Harmful?

Images of poor working conditions and polluting factories from decades ago still linger in the minds of many Western consumers and brand owners.

While problems can exist anywhere, the landscape has fundamentally changed. Under pressure from government regulation and the demands of major global brands, leading Chinese manufacturers now adhere to strict international social compliance (like BSCI) and environmental standards (like OEKO-TEX® and GRS).

This is a topic we are incredibly passionate about. Our clients' customers are demanding sustainability and ethical production, and we are proud to deliver it. We are regularly audited under the BSCI (Business Social Compliance Initiative) framework to ensure fair labor practices. Our materials are often OEKO-TEX® certified to be free of harmful substances, and we are seeing a huge demand for our GRS (Global Recycled Standard) certified sustainable swimwear. A modern, professional factory sees these standards not as a burden, but as a competitive advantage that attracts high-quality, long-term partners. When you are vetting a factory, simply ask to see their latest audit reports and certifications. A proud, ethical partner will be happy to share them.

Myth #6: Will I Have to Order Millions of Pieces?

Many startups are intimidated by the idea of Chinese manufacturing, imagining they'll be forced to place an order for a million units, which is far beyond their capacity.

While China is the king of mass production, its manufacturing ecosystem is also incredibly flexible. Many factories, especially those looking to build relationships with emerging brands, offer reasonable MOQs (Minimum Order Quantities) that are achievable for startups, especially if you are smart about your design and material choices.

We've discussed this before, but it's a myth worth busting again. The "million-piece order" is a relic of a time when factories only served mega-brands. Today, the market is different. We understand that new brands need to test the market. Our MOQs are based on the real-world minimums from our material suppliers. As I mentioned before, a smart strategy like consolidating your color palette across a few styles can make our MOQs very manageable. The key is to have an open conversation with your potential partner about your goals and budget. A good factory will work with you to find a solution, seeing your initial small order as an investment in a future successful brand.

Myth #7: Is the Supply Chain Unreliable and Slow?

Recent global events have highlighted supply chain vulnerabilities, leading some to believe that sourcing from China is inherently risky and slow.

The COVID-19 pandemic created unprecedented global disruptions. However, China's supply chain has proven to be one of the most resilient and fastest to recover in the world. Its world-class infrastructure, deep domestic supply base, and massive production capacity create a level of speed and reliability that is difficult to replicate elsewhere.

While no supply chain is immune to global events, China's is uniquely robust. Unlike in some countries where a factory might have to import every single component (fabric, thread, elastic, hardware), we source the vast majority of our high-quality materials from domestic suppliers within our province. This dramatically reduces lead times and insulates us from many international shipping risks. Our proximity to major ports like Shantou and Shenzhen means that once your goods are produced, they are on a ship and on their way to you quickly. For brands that need a balance of speed, cost, and quality, China's integrated supply chain remains the most powerful and reliable engine of global manufacturing.

Conclusion

Sourcing lingerie from China in 2026 is about partnership and knowledge. By moving past these outdated myths, you can unlock the incredible potential of the world's most advanced supply chain to build your brand.

Frequently Asked Questions (FAQ)

1. Do I need to visit the factory in China in person?

While it's no longer essential thanks to video calls and third-party inspectors, visiting your factory for the first time is highly recommended. It helps build a strong personal relationship, allows you to see their operations firsthand, and gives you a much deeper understanding of the production process.

2. What are the typical payment terms with a Chinese manufacturer?

The most common payment term is a 30% deposit upfront to purchase raw materials and a 70% balance payment upon completion of the order, before shipment. Some factories may require 50%/50%. These terms are often negotiable based on the size of the order and your relationship with the factory.

3. How long does production take?

After the pre-production sample is approved, a typical production run for lingerie takes between 45 and 90 days. This depends on the complexity of the product, the size of the order, and the factory's current production schedule.

4. What is the difference between a factory and a trading company?

A factory (like us) directly manufactures the goods. A trading company is a middleman who takes your order and outsources it to one or more factories. Working directly with a factory generally gives you better communication, more control over quality, and a lower price.