Navegar no complexo cenário dos regulamentos têxteis e padrões de segurança é assustador. Muitas empresas descobrem questões de conformidade tarde demais, levando a recalls de produtos caros, problemas de importação ou até uma responsabilidade legal que prejudica a reputação da marca.

A roupa ativa deve atender a vários padrões de segurança e qualidade, incluindo a certificação Oeko-Tex Standard 100 (garantindo que os têxteis estejam livres de substâncias nocivas), padrões de teste de desempenho e regulamentos específicos da região, como Reach da UE ou CPSIA dos EUA. As certificações éticas de fabricação são cada vez mais importantes para os consumidores conscientes.

Por ter, priorizamos a conformidade e a segurança em todos os nossos produtos para roupas ativas. Nossa experiência em fabricar mais de US $ 30 milhões em vendas anuais para mais de 3.000 lojas nos ensinou a importância crítica de atender aos padrões globais. Deixe -me compartilhar o que aprendemos sobre a navegação no complexo mundo da conformidade, certificações e padrões de fábrica.

Quais certificações são importantes para roupas ativas?

Compreender quais certificações são realmente relevantes pode ser esmagador. Muitas empresas desperdiçam recursos em certificações desnecessárias enquanto perdem aquelas críticas para seus mercados -alvo.

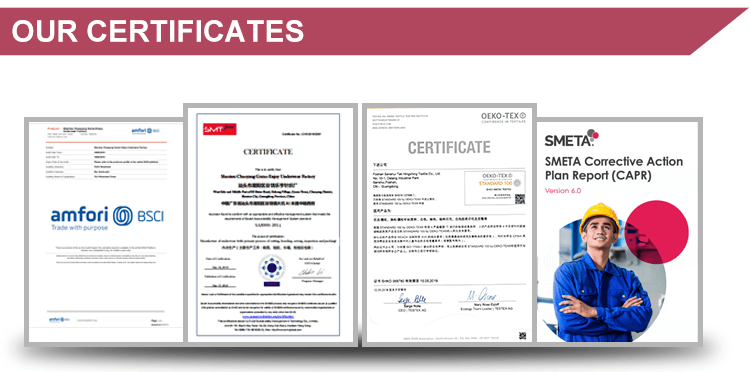

As principais certificações para roupas ativas incluem o Standard 100 OEKO-TEX (garantindo que os têxteis estejam livres de substâncias nocivas), ISO 9001 (Sistemas de Gerenciamento da Qualidade), auditorias de conformidade social como BSCI ou WRAP (fabricação ética) e certificações de sustentabilidade opcionais como Bluesign® (produção ambientalmente amigável) ou GRS (para conteúdo reciclado).

Por ter, mantemos várias certificações para garantir que nossas roupas ativas atendam aos padrões internacionais de segurança, qualidade e fabricação ética. Aqui está o que você precisa saber sobre certificações relevantes:

Certificações essenciais de segurança do produto

Padrão oeko-tex 100

O que certifica: Têxteis testados quanto a substâncias nocivas

Importância: Crítico para produtos com contato com a pele prolongada

Escopo de teste: Testes para substâncias regulamentadas e não regulamentadas

Validade: Requer renovação anual e testes regulares

O Standard 100 Oeko-Tex é particularmente importante para roupas ativas devido à natureza íntima do produto e ao contato prolongado com a pele durante a transpiração. A certificação garante que todos os componentes - de tecidos a threads, elásticos e impressões - ofereçam requisitos estritos de segurança.

Certificação de proteção UV

O que certifica: Capacidade do tecido de bloquear os raios UV prejudiciais

Importância: Relevante para desgaste do desempenho ao ar livre

Método de teste: UPF (fator de proteção ultravioleta) Classificação

Padrão comum: AS/NZS 4399 ou AATCC 183

Para roupas ativas ao ar livre, a certificação UPF fornece reivindicações verificadas de proteção solar que podem ser um ponto de venda valioso.

Certificações de gestão da qualidade

ISO 9001

O que certifica: Sistemas de gerenciamento da qualidade

Importância: Demonstra abordagem sistemática da qualidade

Requisitos: Procedimentos documentados, auditorias internas, melhoria contínua

Beneficiar: Reduz o risco de inconsistências de qualidade

A certificação ISO 9001 indica que um fabricante implementou processos sistemáticos de gerenciamento da qualidade, o que é particularmente importante para produtos técnicos como roupas ativas, onde a consistência do desempenho é crítica.

Certificações de conformidade social

Iniciativa de conformidade social de negócios (BSCI)

O que certifica: Práticas de trabalho éticas e condições de trabalho

Importância: Verifica a fabricação ética

Áreas de auditoria: Salários justos, horário de trabalho, saúde e segurança, sem trabalho infantil

Processo: Auditorias independentes de terceiros

Produção Acreditada Responsável Mundial (WRAP)

O que certifica: Fabricação legal, humana e ética

Importância: Programa de conformidade social reconhecida internacionalmente

Áreas de foco: Práticas trabalhistas, condições de trabalho, responsabilidade ambiental

Níveis: Diferentes níveis de certificação com base na conformidade

As certificações de conformidade social tornaram -se cada vez mais importantes à medida que consumidores e varejistas exigem transparência sobre as condições de fabricação. Muitos varejistas importantes agora exigem essas certificações de seus fornecedores.

Certificações de sustentabilidade (opcional)

Bluesign®

O que certifica: Produção têxtil ambientalmente amigável

Importância: Abordagem abrangente da fabricação sustentável

Foco: Segurança química, eficiência de recursos, segurança do consumidor

Beneficiar: Apela a marcas ambientalmente conscientes

Padrão reciclado global (GRS)

O que certifica: Conteúdo reciclado em produtos

Importância: Relevante para roupas ativas usando poliéster reciclado

Requisitos: Conteúdo mínimo reciclado, cadeia de verificação de custódia

Beneficiar: Suporta reivindicações de sustentabilidade

Embora não sejam essenciais para todas as roupas ativas, as certificações de sustentabilidade podem fornecer vantagens de marketing significativas e apelar aos consumidores ambientalmente conscientes.

| Certificação | Essencial ou opcional | Faixa de custo típica | Frequência de renovação |

|---|---|---|---|

| Padrão oeko-tex 100 | Essencial | US $ 1.000-3.000 | Anual |

| ISO 9001 | Recomendado | US $ 5.000-15.000 | 3 anos com auditorias anuais |

| BSCI/WRAP | Cada vez mais essencial | US $ 3.000-8.000 | Anual ou bienal |

| Bluesign® | Opcional | US $ 10.000-25.000 | Anual |

| GRS | Opcional (essencial para reivindicações recicladas) | US $ 5.000-15.000 | Anual |

Para obter informações detalhadas sobre tecnologia e materiais ativos que podem exigir certificações específicas, visite nosso guia abrangente: Roupas ativas & Tecnologia de uso de ioga & Materiais: um guia do comprador para tecidos de desempenho, construção & Durabilidade.

Quais regulamentos regionais devem se encontrar com roupas ativas?

Diferentes mercados têm requisitos regulatórios distintos. Deixar de atender a esses padrões pode resultar em produtos rejeitados na alfândega, recalls forçados ou penalidades legais.

A moda ativa deve cumprir os regulamentos específicos da região, incluindo alcance da UE (restringindo produtos químicos perigosos), CPSIA dos EUA (especialmente para roupas ativas para jovens), advertências da Proposição 65 da Califórnia e requisitos de rotulagem têxteis específicos do país. Cada mercado possui necessidades exclusivas de conformidade que devem ser atendidas antes da importação.

Por ter, ajudamos nossos parceiros a navegar no cenário complexo dos regulamentos globais. Aqui está o que você precisa saber sobre os principais requisitos regionais:

Regulamentos da América do Norte

Estados Unidos

Lei de Melhoria de Segurança de Produtos de Consumidores (CPSIA)

- Aplicabilidade: Particularmente relevante para roupas ativas para jovens

- Requisitos: Teste para chumbo, ftalatos e outras substâncias restritas

- Documentação: Certificado de Produto Infantil (CPC) para produtos para jovens

Requisitos da Comissão Federal de Comércio (FTC)

- Lei de Identificação de Produtos de Fibra Têxtil: Rotulagem precisa de conteúdo de fibra

- Regra de rotulagem de cuidados: Instruções de cuidados claros

- Feito nos EUA reivindicações: Padrões rígidos para reivindicações de país de origem

Proposição 65 da Califórnia

- Exigência: Etiquetas de aviso para produtos contendo produtos químicos listados

- Relevância: Particularmente importante se os materiais contiverem substâncias listadas

- Opções de conformidade: Prove os produtos não contêm produtos químicos listados ou fornecem avisos

Canadá

Lei de Segurança de Produtos de Consumo do Canadá

- Requisitos: Semelhante a nós, padrões com algumas variações

- Lei de rotulagem têxtil: Rotulagem bilíngue (inglês/francês)

- Requisitos de inflamabilidade: Conformidade com os padrões de inflamabilidade

Regulamentos da União Europeia

Alcance (registro, avaliação, autorização e restrição de produtos químicos)

- Escopo: Restringe inúmeras substâncias perigosas em produtos de consumo

- Requisitos: Conformidade com restrições de substâncias, documentação

- Atualizações: Adições regulares à lista de substâncias restritas

Diretiva de Segurança de Produto Geral

- Exigência: Os produtos devem ser seguros para uso pretendido

- Documentação: Arquivo técnico demonstrando avaliação de segurança

Regulamento de rotulagem têxtil

- Requisitos: Teor de fibra em todos os idiomas da UE, instruções de atendimento

- Próximas mudanças: Potenciais novos requisitos de rotulagem de sustentabilidade

Regulamentos da Ásia-Pacífico

Austrália/Nova Zelândia

- Padrões de segurança do produto: Conformidade com os padrões AS/NZS

- Lei do Consumidor Australiano: Requisitos de segurança e rotulagem do produto

- Lei de Concorrência e Consumidor: Verdade nos requisitos de publicidade

Japão

- Lei de rotulagem de qualidade de bens domésticos: Requisitos de rotulagem específicos

- Padrões industriais japoneses (JIS): Padrões de qualidade e segurança

China

- Padrões GB: Conformidade com os padrões nacionais de têxteis

- Inspeção do CIQ: Inspeção potencial na alfândega

- Requisitos de rotulagem: Rotulagem de língua chinesa

Para obter informações sobre como navegar na cadeia de suprimentos e considerações logísticas em diferentes regiões, visite nosso guia sobre Da fábrica ao armazém: compreensão de MOQs, tempo de entrega & Logística em roupas ativas & O fornecimento de uso de ioga.

Como você avalia os padrões de fábrica e a fabricação ética?

Garantir a fabricação ética é cada vez mais importante para consumidores e varejistas. Muitas empresas lutam para verificar as condições da fábrica e as práticas éticas, especialmente na fabricação do exterior.

A avaliação dos padrões da fábrica envolve a avaliação da conformidade social (práticas trabalhistas, condições de trabalho, salários justos), responsabilidade ambiental (gerenciamento de resíduos, uso de recursos), sistemas de gerenciamento da qualidade (padrões de produção consistentes) e transparência (disposição de compartilhar informações e permitir auditorias).

Por ter, estamos comprometidos com as práticas de fabricação éticas e recebemos as auditorias de clientes de nossas instalações. Veja como avaliar efetivamente os padrões de fábrica:

Avaliação de conformidade social

Áreas -chave para avaliar

Práticas trabalhistas

- Horário de trabalho Conformidade com as leis locais

- Pagamento de salário justo e compensação de horas extras

- Direitos de liberdade de associação

- Sem criança ou trabalho forçado

Condições de trabalho

- Medidas de segurança no local de trabalho

- Procedimentos e saídas de emergência

- Ventilação adequada e controle de temperatura

- Iluminação e ergonomia adequadas

Bem -estar dos funcionários

- Acesso a intervalos e períodos de descanso

- Água potável limpa e instalações de saneamento

- Mecanismos de queixas

- Políticas anti-assédio

Métodos de verificação

Auditorias de terceiros

- BSCI (Iniciativa de conformidade social de negócios)

- WRAP (Produção Credenciada Responsável em todo o mundo)

- SedEx/Smeta (Troca de dados éticos do fornecedor)

- SA8000 (Social Accountability International)

Avaliação direta

- Visitas de instalação (anunciadas e sem aviso prévio)

- Entrevistas de trabalhadores longe da administração

- Revisão do documento (folha de pagamento, registros de tempo, políticas)

- Consulta local das partes interessadas

Avaliação de responsabilidade ambiental

Áreas -chave para avaliar

Gerenciamento de recursos

- Medidas de uso e conservação de água

- Eficiência energética e uso de energia renovável

- Fornecimento de matéria -prima e eficiência

Controle de poluição

- Sistemas de tratamento de águas residuais

- Controles de emissão de ar

- Práticas de gerenciamento químico

Gerenciamento de resíduos

- Estratégias de redução de resíduos têxteis

- Programas de reciclagem

- Manuseio de resíduos perigosos

Métodos de verificação

Certificações ambientais

- ISO 14001 (gestão ambiental)

- Sistema Bluesign® (padrão ambiental específico de têxtil)

- ZDHC (descarga zero de produtos químicos perigosos)

Avaliação direta

- Revisão de Políticas Ambientais

- Inspeção da instalação de controles ambientais

- Observação de gerenciamento de resíduos

- Contas de serviços públicos e registros de consumo

Avaliação de gestão da qualidade

Áreas -chave para avaliar

Sistemas de controle de qualidade

- Inspeção material de entrada

- Verificações de qualidade em processo

- Inspeção final do produto

- Protocolos de teste para atributos de desempenho

Documentação e rastreabilidade

- Documentação de fornecimento de material

- Registros de produção

- Resultados dos testes de qualidade

- Sistemas de rastreamento de lote

Melhoria contínua

- Metodologias de solução de problemas

- Rastreamento e análise de defeitos

- Programas de treinamento de funcionários

- Manutenção do equipamento

Lista de verificação de avaliação de fábrica

Ao avaliar potenciais parceiros de fabricação, use esta lista de verificação:

| Categoria | Questões -chave |

|---|---|

| Conformidade social |

• Que certificações de conformidade social eles possuem? • Quando foi a última auditoria de terceiros? • Eles estão dispostos a compartilhar relatórios de auditoria? • Qual é a taxa de rotatividade dos funcionários? |

| Práticas ambientais |

• Quais sistemas de gestão ambiental estão em vigor? • Como eles lidam com as águas residuais e os resíduos têxteis? • Eles têm programas de eficiência energética? • Quais protocolos de gerenciamento químico eles seguem? |

| Sistemas de qualidade |

• Que certificações de qualidade eles mantêm? • Que equipamento de teste eles têm internamente? • Como eles lidam com problemas de qualidade e defeitos? • Eles podem fornecer métricas de desempenho de qualidade? |

| Transparência |

• Eles estão dispostos a permitir visitas às instalações? • Eles divulgam todos os locais de produção (incluindo subcontratados)? • Eles fornecerão acesso aos trabalhadores para entrevistas? • Como eles comunicam os desafios de produção? |

Para obter informações sobre o desenvolvimento de sua própria linha de roupas ativas com fabricantes de éticos, explore nosso recurso em Sua marca, seu produto: o guia completo para a marca própria (OEM/ODM) Ativa & Manufatura de uso de ioga.

Como você garante conformidade e qualidade contínuas?

A certificação inicial é apenas o começo. Muitas empresas não conseguem implementar sistemas para o monitoramento contínuo de conformidade, levando a desvios de padrões ao longo do tempo.

Garantir a conformidade contínua requer a implementação de protocolos de testes regulares (teste de material, teste de desempenho, teste de durabilidade), realização de auditorias periódicas de fábrica (visitas programadas e surpresas), mantendo sistemas claros de documentação e estabelecendo procedimentos de ação corretiva para abordar quaisquer problemas que surgirem.

No Ter, desenvolvemos sistemas abrangentes para manter os padrões de conformidade e qualidade em todos os nossos processos de fabricação. Aqui está nossa abordagem para a conformidade contínua:

Protocolos de teste regulares

Teste de material

Freqüência: Todo lote de entrada

Testes realizados:

- Verificação de conteúdo de fibra

- Triagem de substâncias restritas

- Propriedades físicas (peso, alongamento, recuperação)

- Rapidez de cor

Teste de produção

Freqüência: Durante a produção em intervalos definidos

Testes realizados:

- Verificação do atributo de desempenho

- Verificações de qualidade de construção

- Estabilidade dimensional

- Padrões de aparência

Teste acabado de produto

Freqüência: Cada lote de produção

Testes realizados:

- Teste de desempenho completo

- Lavar amostragem de durabilidade

- Inspeção final da qualidade

- Integridade da embalagem

Cronograma de auditoria e inspeção

Auditorias internas

Freqüência: Mensalmente

Áreas de foco:

- Processo de produção Aderência

- Implementação de controle de qualidade

- Padrões de segurança e conformidade

- Pretilidade da documentação

Auditorias de terceiros

Freqüência: Anualmente ou conforme exigido por certificações

Tipos:

- Auditorias de conformidade social

- Auditorias ambientais

- Auditorias do sistema de gestão da qualidade

- Renovações de certificação específicas

Auditorias de clientes

Freqüência: Conforme solicitado pelos clientes

Abordagem:

- Política de portas abertas para visitas ao cliente

- Compartilhamento transparente de documentação

- Acesso a áreas de produção

- Entrevistas de trabalhadores conforme apropriado

Sistemas de documentação

Manter a documentação abrangente é essencial para demonstrar conformidade:

- Certificados de materiais: Documentação para todos os materiais de entrada

- Relatórios de teste: Resultados de todos os testes realizados

- Registros de produção: Documentação detalhada de fabricação

- Documentos de certificação: Certificados atuais e relatórios de auditoria

- Registros de treinamento: Documentação do treinamento de funcionários

- Relatórios de ação corretiva: Registros de questões e resoluções

Para obter informações detalhadas sobre padrões de controle de qualidade e protocolos de teste, visite nosso recurso abrangente em Garantir a excelência do produto: controle de qualidade & Padrões de fabricação para roupas ativas & O fornecimento de uso de ioga.

Conclusão

Navegar em conformidade, certificações e padrões de fábrica é essencial para o fornecimento de roupas ativas com confiança. Ao entender as certificações relevantes, os regulamentos regionais, os padrões éticos de fabricação e os requisitos contínuos de conformidade, as empresas podem proteger sua reputação de marca enquanto fornecem produtos seguros e de alta qualidade aos consumidores.

Por ter, nosso compromisso com a conformidade e a fabricação ética tem sido fundamental para o nosso sucesso em produzir mais de US $ 30 milhões em vendas anuais que atendem a mais de 3.000 lojas, mantendo os mais altos padrões de segurança e qualidade do produto.

Para uma visão geral abrangente de toda a categoria de roupas ativas, incluindo tendências de mercado e oportunidades de negócios, visite nosso Guia Ultimate B2B para o fornecimento & Vendendo roupas ativas & Desgaste de ioga.

Perguntas frequentes (FAQ)

Qual é a certificação mais importante para roupas ativas?

O Oeko-Tex Standard 100 é geralmente considerado a certificação mais essencial para roupas ativas, pois verifica que todos os componentes estão livres de substâncias nocivas-críticas para produtos com contato prolongado com a pele durante o exercício.

Com que frequência as roupas ativas devem ser testadas para conformidade?

O teste de material deve ocorrer para cada novo lote de material, enquanto o teste de produto acabado deve ser realizado para cada execução de produção. Revisões abrangentes de conformidade, incluindo renovações de certificação, geralmente seguem os ciclos anuais.

Qual é a diferença entre as certificações BSCI e Wrap?

Tanto a fabricação ética, mas o BSCI (Iniciativa de Conformidade Social de Negócios) é mais comum nos mercados europeus e segue uma abordagem de melhoria contínua, enquanto o WRAP (produção credenciada responsável mundial) é mais prevalente nos mercados norte -americanos e usa um sistema de nível de certificação.

Solicite relatórios de auditoria recentes de terceiros, verifique a validade da certificação por meio dos órgãos de certificação, conduza suas próprias visitas de fábrica (anunciadas e sem aviso prévio, se possível) e converse com outros clientes que trabalham com a fábrica.

Que documentação devo solicitar a possíveis parceiros de fabricação?

Solicite cópias atuais das certificações relevantes (OEKO-TEX, ISO, conformidade social), relatórios de auditoria recentes de terceiros, relatórios de teste para produtos semelhantes e suas políticas escritas sobre controle de qualidade, responsabilidade social e gestão ambiental.

Como os regulamentos regionais diferem para roupas ativas?

As principais diferenças incluem requisitos de rotulagem (idioma, conteúdo), restrições químicas (o alcance da UE é geralmente mais rigoroso que os regulamentos dos EUA), padrões de inflamabilidade e requisitos específicos para produtos comercializados para jovens.

Obtenha uma cotação grátis para seus projetos de roupas ativas