Da fábrica ao armazém: compreensão de MOQs, tempo de entrega & Logística em roupas ativas & O fornecimento de uso de ioga?

As complexidades da cadeia de suprimentos costumam capturar empresas de surpresa. Os prazos de entrega inesperados, atrasos no envio e problemas alfandegários podem interromper o planejamento de inventário e decepcionar os clientes que estão aguardando seus produtos para roupas ativas.

O fornecimento bem-sucedido de roupas ativas requer a compreensão do tempo típico de entrega (60-90 dias desde a ordem até a entrega), quantidades mínimas de pedidos (normalmente 500-3.000 unidades por estilo, dependendo da personalização) e considerações internacionais de remessa. O planejamento desses fatores impede a escassez de estoque e garante lançamentos suaves de produtos.

Por ter, simplificamos nossos processos de cadeia de suprimentos para fornecer previsibilidade para nossos parceiros. Nossa experiência em dimensionar a produção para mais de US $ 30 milhões em vendas anuais que atendem a mais de 3.000 lojas nos ensinaram lições valiosas sobre o gerenciamento da logística do fornecimento de roupas ativas. Deixe -me compartilhar o que aprendemos sobre a navegação desses elementos críticos da cadeia de suprimentos.

Que quantidades mínimas de pedidos você deve esperar?

As quantidades mínimas de pedidos (MOQs) são frequentemente as primeiras empresas de obstáculos que enfrentam ao adquirir roupas ativas. Sem entender os requisitos típicos, é fácil se surpreender com os mínimos que excedem seu orçamento inicial ou capacidade de armazenamento.

As quantidades mínimas de pedidos para roupas ativas geralmente variam de 500 a 3.000 unidades por estilo/cor, dependendo do nível de personalização. Os fatores que influenciam os MOQs incluem a seleção de materiais (estoque vs. costume), complexidade do projeto, requisitos de eficiência de fabricação e seu status de relacionamento com o fabricante.

Quando começamos a fabricar roupas ativas, mantemos MOQs altos devido à complexidade da produção. Hoje, desenvolvemos opções mais flexíveis para acomodar vários tamanhos de negócios, mantendo a qualidade e a eficiência. Aqui está o que você precisa saber sobre MOQs:

Fatores MOQ e requisitos típicos

| Fator | Faixa MOQ mais baixa | Faixa MOQ mais alta |

|---|---|---|

| Nível de personalização | Designs padrão com marca: 500 unidades | Designs totalmente personalizados: 2.000-3.000 unidades |

| Seleção de Materiais | Materiais de estoque: 500-1.000 unidades | Materiais personalizados: mais de 3.000 unidades |

| Opções de cores | Cores padrão: 500 unidades por cor | Cores tingidas personalizadas: mais de 1.000 unidades por cor |

| Complexidade do produto | Estilos básicos (leggings, tanques): MOQs mais baixos | Estilos complexos (jaquetas, sutiãs): MOQs mais altos |

Estratégias MOQ para diferentes tamanhos de negócios

Startups e pequenas marcas

Se você está apenas entrando no mercado de roupas ativas, considere essas abordagens:

- Comece com ODM (Fabricação de Design Original) usando os designs existentes do fabricante com sua marca

- Concentre-se em 1-2 estilos principais em 1-2 cores para atender aos requisitos mínimos

- Considere materiais de estoque em vez de tecidos personalizados

- Faça parceria com fabricantes que oferecem MOQs mais baixos para projetos padrão

Por ter, oferecemos baixos MOQs líderes do setor de apenas 500 peças por estilo para designs padrão com a marca, tornando a marca própria acessível a marcas emergentes.

Marcas de tamanho médio

À medida que sua empresa cresce, você pode otimizar o MOQS através de:

- Consolidação de pedidos para vários estilos para atingir descontos de volume

- Desenvolvendo um programa de cores central com cores de sotaque sazonal

- Equilibrando elementos personalizados e padrão para gerenciar mínimos

- Construindo padrões de pedidos consistentes para negociar MOQs mais baixos

Grandes varejistas

Para compradores substanciais de volume:

- Negocie MOQs com base em compromissos anuais de compra

- Desenvolva materiais exclusivos com fornecedores por meio de garantias de volume

- Crie cronogramas de entrega escalonados para gerenciar o fluxo de produção

- Estabelecer programas de inventário gerenciados por fornecedores com fabricantes

Para obter informações detalhadas sobre o desenvolvimento de sua própria linha de roupas ativas, visite nosso guia abrangente: Sua marca, seu produto: o guia completo para a marca própria (OEM/ODM) Ativa & Manufatura de uso de ioga.

Que tempo de entrega você deve planejar?

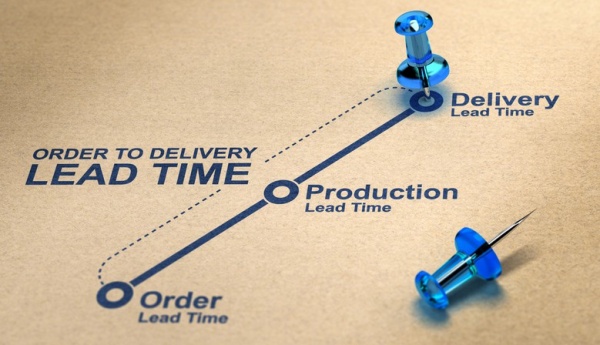

As expectativas irrealistas de tempo de entrega podem inviabilizar os lançamentos de produtos e os planos de marketing. Muitas empresas subestimam o tempo necessário, desde a colocação de pedidos até a entrega, levando à escassez de estoque e aos clientes decepcionados.

A linha do tempo típica para a produção de roupas ativas inclui amostragem (2-3 semanas), fornecimento de materiais (3-4 semanas), produção (4-6 semanas), controle e teste de qualidade (1 semana) e envio (2-6 semanas, dependendo do destino e do método). O planejamento para um tempo total de liderança de 12 a 20 semanas do conceito à entrega garante gerenciamento realista de inventário.

Por ter, fornecemos estimativas de tempo de entrega transparentes com base em nossa extensa experiência de fabricação. Aqui está um detalhamento detalhado dos componentes da linha do tempo:

Fase de desenvolvimento e amostragem

Amostragem inicial: 2-3 semanas

- Confirmação do projeto: 3-5 dias

- Preparação do material: 5-7 dias

- Produção de amostra: 5-7 dias

- Avaliação e feedback da amostra: 3-5 dias

Amostragem revisada (se necessário): 1-2 semanas

- Implementação de ajuste: 3-5 dias

- Produção de amostra revisada: 5-7 dias

- Aprovação final: 2-3 dias

Fase de pré-produção

Fornecimento de material: 3-4 semanas

- Compras de tecido: 2-3 semanas

- GRAPAS E ELÁSTICOS: 2-3 semanas

- Correspondência de cores e aprovação: 1-2 semanas

Configuração de produção: 1-2 semanas

- Classificação de padrões e fabricação de marcadores: 3-5 dias

- Planejamento de produção: 3-5 dias

- Aprovação da amostra de pré-produção: 3-5 dias

Fase de produção

Produção em massa: 4-6 semanas

- Corte: 5-7 dias

- Costura e montagem: 15-25 dias

- Controle de qualidade durante a produção: em andamento

- Acabamento e corte: 3-5 dias

Controle final da qualidade: 1 semana

- Inspeção final: 3-5 dias

- Teste de amostras de produção: 3-5 dias

- Embalagem e preparação para o envio: 2-3 dias

Fase de envio

Tempo de envio: 2-6 semanas

- Frete aéreo: 5 a 10 dias (incluindo liberação aduaneira)

- Frete marítimo: 3-6 semanas (incluindo liberação aduaneira)

- Transporte terrestre para destino final: 2-7 dias

Variáveis de tempo de entrega

Vários fatores podem afetar os prazos de entrega:

| Variável | Impacto potencial | Estratégia de mitigação |

|---|---|---|

| Tempo sazonal | +1-3 semanas durante as estações de pico | Ordem durante as fissuras da indústria |

| Disponibilidade de material | +2-4 semanas para materiais especiais | Confirme a disponibilidade do material antes de fazer o pedido |

| Encomendar complexidade | +1-2 semanas para designs complexos | Simplifique as ordens iniciais para estabelecer a linha de base |

| Interrupções no envio | Atrasos imprevisíveis | Construa o tempo de buffer para o planejamento |

Para obter informações sobre as tendências do mercado que podem afetar seu planejamento de inventário, visite nossa análise detalhada: Compreendendo a roupa ativa & Mercado de desgaste de ioga: tendências, demografia & Oportunidades para compradores B2B.

As complexidades de transporte internacional podem afetar significativamente os custos e os cronogramas. Muitas empresas encontram taxas inesperadas, atrasos aduaneiros e problemas de conformidade ao importar roupas ativas.

O envio internacional eficaz para roupas ativas exige a compreensão dos termos de remessa (FOB, EXW, DDP), selecionando métodos de frete apropriados com base na linha do tempo e no orçamento, preparando a documentação adequada para a liberação aduaneira e o planejamento de impostos e impostos que podem adicionar 15-30% aos custos do produto.

Por ter, ajudamos nossos parceiros a navegar pelas complexidades do transporte e logística internacionais. Aqui está o que você precisa saber:

Termos e responsabilidades de envio

Compreender os termos de remessa é crucial para a alocação clara de responsabilidade:

FOB (grátis a bordo)

- Responsabilidade do fabricante: Entrega de mercadorias à porta/embarcação designada

- Responsabilidade do comprador: Frete internacional, seguro, autorização aduaneira, entrega final

- Vantagens: Menor custo inicial, controle sobre o método de envio

- Melhor para: Importadores experientes com encaminhadores de carga estabelecidos

EXW (EX Works)

- Responsabilidade do fabricante: Disponibilizar mercadorias em suas instalações

- Responsabilidade do comprador: Todo transporte, liberação de exportação/importação, seguro

- Vantagens: Preço potencialmente menor, controle completo

- Melhor para: Compradores com fortes recursos de logística ou agentes locais

DDP (entregue entregue)

- Responsabilidade do fabricante: Todo transporte, liberação aduaneira, deveres, entrega ao destino final

- Responsabilidade do comprador: Receber mercadorias no local designado

- Vantagens: Simplicidade, custo previsível

- Melhor para: Empresas novas para importar ou buscar simplicidade

Comparação de métodos de frete

| Método | Linha do tempo | Custo | Melhor para |

|---|---|---|---|

| Frete aéreo | 5-10 dias | High (US $ 5-10/kg) | Remessas urgentes, bens de baixo volume e alto valor |

| Express Courier | 3-7 dias | Muito alto (US $ 10-20/kg) | Amostras, remessas muito pequenas, extrema urgência |

| Frete marinho (FCL) | 30-45 dias | Baixo (US $ 0,5-1,5/kg) | Remessas grandes preenchendo um recipiente |

| Frete marinho (LCL) | 35-50 dias | Médio (US $ 1,5-3/kg) | Remessas de tamanho médio não preencherem um recipiente |

Requisitos de documentação

A documentação adequada é essencial para a liberação alfândega suave:

Documentos essenciais

- Fatura comercial: Descrição detalhada, quantidades, valores

- Lista de embalagem: Conteúdo detalhado por caixa/palete

- Bill of Lading/Airway Bill: Documento de transporte

- Certificado de origem: Verifica o país de fabricação

- Declaração têxtil: Informações de conteúdo de fibra

Documentação adicional (específico do mercado)

- Relatórios de teste de laboratório: Documentação de teste de segurança

- Certificados OEKO-TEX: Verificação dos padrões de segurança

- Declarações de conformidade: Requisitos específicos do mercado

- Licenças de importação: Exigido em alguns países

Deveres, impostos e custos adicionais

Ao calcular os custos desembarcados, considere estas despesas adicionais:

Direitos de importação

- Classificação: Owear ativo normalmente se enquadra no Código HS 6112 ou 6114

- Taxas de serviço: Variar por país (normalmente 5-20% do valor do produto)

- Acordos comerciais: Pode fornecer tarefas reduzidas ou zero

Impostos

- Imposto sobre valor agregado (IVA): Aplicado em muitos países (normalmente 10-25%)

- Imposto sobre bens e serviços (GST): Aplicado em países como a Austrália, Canadá

- Imposto sobre vendas: Aplicado nos EUA em nível estadual/local

Custos adicionais

- Taxas de corretor aduaneiro: $ 100-300 por remessa

- Taxas de manutenção do porto: Para remessas marítimas para certos países

- Taxas de processamento de mercadorias: Cobranças administrativas

- Armazenamento/demurrage: Cobranças de coleta de contêiner tardia

- Entrega de última milha: Transporte para destino final

Para obter informações sobre processos de controle de qualidade que devem ocorrer antes do envio, visite nosso recurso em Garantir a excelência do produto: controle de qualidade & Padrões de fabricação para roupas ativas & O fornecimento de uso de ioga.

Como você gerencia o inventário de maneira eficaz?

A má gestão de inventário leva a excesso de ações que aprimoram capital ou ações decepcionantes de decepcionantes. Muitas empresas lutam para equilibrar esses riscos concorrentes ao lidar com longos prazos de entrega.

O gerenciamento eficaz de inventário de roupas ativas combina previsão orientada a dados, níveis estratégicos de estoque de segurança (normalmente fornecimento de 30 a 60 dias) e classificação de inventário em camadas (estilos principais mantidos em níveis mais altos de estoque que os itens sazonais). A implementação de pontos de reordenação com base nos tempo de entrega, em vez de níveis arbitrários, ajuda a prevenir as ações, minimizando o excesso de inventário.

Por ter, ajudamos nossos parceiros a desenvolver estratégias de inventário que equilibram a disponibilidade com a eficiência de capital. Aqui está nossa abordagem para o gerenciamento eficaz de inventário:

Métodos de previsão de inventário

A previsão precisa é a base do gerenciamento de inventário:

Análise de vendas históricas

- Método da linha de base: Usando vendas anteriores para projetar demanda futura

- Fator de crescimento: Aplicando as taxas de crescimento da categoria aos dados históricos

- Ajustes de sazonalidade: Contabilidade para padrões de demanda cíclica

Previsão baseada no mercado

- Abordagem de participação de mercado: Estimar o tamanho total do mercado e sua parte

- Análise competitiva: Monitorar a atividade e impacto dos concorrentes

- Incorporação de tendências: Ajustando para tendências de mercado emergentes

Previsão de novos produtos

- Método de produto comparável: Usando o desempenho semelhante ao produto à linha de base

- Dados do mercado de teste: Extrapolando de testes de mercado limitados

- Informações de pré-encomenda: Usando os compromissos do cliente como indicadores

Estratégia de classificação de inventário

Nem todos os estilos de roupas ativas exigem a mesma abordagem de inventário:

| Categoria | Descrição | Estratégia de inventário |

|---|---|---|

| Produtos principais | Estilos básicos, vendedores consistentes | Estoque de segurança mais alta (60-90 dias), reabastecimento regular |

| Produtos sazonais | Cores da moda, edições limitadas | Material de segurança menor (30-45 dias), compra única |

| Novos lançamentos | Ofertas pela primeira vez | Ordem inicial conservadora, capacidade de reordenação rápida |

| Itens especiais | Produtos de nicho (por exemplo, itens de ioga especializados) | Abordagem just-in-time, pedidos orientados à demanda |

Reordenar o cálculo de pontos

Para determinar quando fazer novos pedidos:

Reordenar ponto = (vendas diárias médias × tempo de entrega em dias) + Estoque de segurança

Exemplo de cálculo:

- Vendas diárias médias: 20 unidades

- LEVIE DO LEITO: 90 DIAS

- Estoque de segurança: 30 dias de valor (600 unidades)

- Ponto de reordenação: (20 × 90) + 600 = 2.400 unidades

Quando o inventário cair para 2.400 unidades, faça um novo pedido.

Estratégias de planejamento sazonal

O ativo geralmente tem padrões de demanda sazonal que exigem abordagens especializadas:

- Compra avançada: Compra de inventário sazonal com 4-6 meses de antecedência

- Entregas em fases: Organizando remessas escalonadas para combinar com a curva de vendas

- Estratégia de final de temporada: Planejando o tempo e a profundidade do Markdown

- Análise de transmissão: Identificar quais itens sazonais podem se tornar núcleos

Para obter informações sobre a construção de uma linha de produtos equilibrada que otimiza a eficiência do inventário, visite nosso guia sobre Curadoria de sua coleção: um guia B2B para roupas ativas & Estilos de desgaste de ioga, funções & Opções de material.

Conclusão

Navegar com sucesso MOQs, prazos de entrega e logística é essencial para o fornecimento eficiente de roupas ativas. Ao entender os requisitos do fabricante, planejando prazos realistas, gerenciamento de complexidades internacionais de expedição e implementando estratégias de inventário eficazes, as empresas podem garantir a disponibilidade consistente do produto e otimizar a utilização de capital.

No Ter, fazemos parceria com marcas para criar cadeias de suprimentos simplificadas que equilibram a eficiência da flexibilidade, ajudando nossos clientes a ter sucesso no mercado competitivo de roupas ativas.

Para uma visão geral abrangente de toda a categoria de roupas ativas, incluindo tendências de mercado e oportunidades de negócios, visite nosso Guia Ultimate B2B para o fornecimento & Vendendo roupas ativas & Desgaste de ioga.

Perguntas frequentes (FAQ)

Qual é a menor quantidade de ordem possível para roupas ativas?

O mínimo absoluto normalmente começa em 500 unidades por estilo/cor para designs padrão com marca básica. Quantidades menores podem ser possíveis para execuções de amostras ou através de agregadores que combinam vários pedidos pequenos, mas os custos unitários serão significativamente maiores.

Como posso reduzir os prazos de entrega para a produção de roupas ativas?

Para reduzir o tempo de entrega, considere o uso de materiais de estoque em vez de tecidos personalizados, trabalhe com os fabricantes que mantêm componentes comuns, desenvolvem projetos padronizados que requerem menos tempo de configuração e criam relacionamentos de longo prazo que podem fornecer programação de produção prioritária.

Qual é o método de remessa mais econômico para roupas ativas?

O frete marinho é tipicamente o mais econômico para pedidos maiores (mais de 500 unidades), com custos 70-80% mais baixo que o frete aéreo. No entanto, o tempo de trânsito prolongado (30-45 dias versus 5 a 10 dias para o ar) requer um planejamento mais avançado e níveis de estoque de segurança mais altos.

Como faço para calcular tarefas de importação para roupas ativas?

Os direitos de importação variam de acordo com o país e são normalmente calculados como uma porcentagem do valor do produto (geralmente 5-20%). Consulte um corretor alfandegário para obter taxas específicas em seu mercado e verifique se se aplicarem algum acordo de livre comércio que possa reduzir ou eliminar as tarefas.

Que taxa de rotatividade de inventário devo ter como alvo de roupas ativas?

Uma taxa de rotatividade de inventário saudável para roupas ativas normalmente varia de 4-6 voltas por ano para estilos principais e 6-8 turnos para itens sazonais. Isso equilibra a eficiência de capital com os níveis adequados de estoque para evitar o estoque.

Como os fatores sazonais afetam o fornecimento de roupas ativas?

A capacidade de fabricação é frequentemente restrita durante o pico de produção de produção (normalmente agosto-novembro para mercadorias de férias). Ordens de plano durante períodos fora de pico, quando possível, e espere atrasos em potencial ou MOQs mais altos durante as estações movimentadas.

Obtenha uma cotação grátis para seus projetos de roupas ativas