How to Find Suitable Underwear Manufacturer for Your Business?

Finding the right underwear manufacturer feels overwhelming. With countless options and conflicting information, making a mistake could cost your business thousands in wasted inventory and missed opportunities.

The best approach to finding a suitable underwear manufacturer is to clearly define your needs, research industry clusters, evaluate quality standards, assess production capabilities, compare pricing structures, check references, establish clear communication, and consider geographical factors affecting tariffs and supply chain efficiency.

The underwear manufacturing landscape has changed dramatically in recent years. While price, order quantity and lead time were once the main concerns, today's global trade tensions and shifting tariffs have created a more complex decision-making environment. Let me walk you through the key considerations based on my experience working with brands of all sizes.

Understanding Your Needs: What Should You Consider First?

Defining your requirements seems simple, but I've seen countless businesses waste time and money by skipping this crucial step. The wrong manufacturer match can lead to quality issues, missed deadlines, and frustrated customers.

Before contacting manufacturers, determine your target market, price points, quality standards, minimum order quantities, sustainability requirements, and timeline needs. A luxury lingerie brand requires different manufacturing capabilities than a mass-market basics line.

When I started in this industry, I made the mistake of approaching manufacturers without clearly defining what I needed. One client came to us after wasting six months with a factory that couldn't properly execute their technical designs - they hadn't verified the factory's experience with complex underwire construction techniques.

Different business models require different manufacturing partners. If you're a DTC brand, your needs will differ significantly from those of an importer or department store supplier. Consider these key differences:

Business Model Considerations

| Business Type | Key Manufacturing Requirements |

|---|---|

| DTC Brand | Smaller MOQs, higher quality, flexibility in design, strong online product presentation |

| Retail Chain | Larger volumes, strict compliance, consistent quality, competitive pricing |

| Department Store | Premium finishes, branded packaging, higher price points, unique design elements |

| Discount/Off-Price | Very competitive pricing, simpler designs, larger volumes, faster production |

Your product category also matters. A manufacturer specializing in basic cotton briefs might not have the technical expertise for complex shapewear or underwire bras. At HAVING, we've invested heavily in specialized equipment and skilled workers to handle everything from simple knit boxers to technically complex period underwear and shapewear pieces.

Researching Potential Manufacturers: Where Should You Look?

I've seen many businesses waste months searching globally when they should have focused on established manufacturing clusters. This scattershot approach often leads to partnerships with unvetted factories and disappointing results.

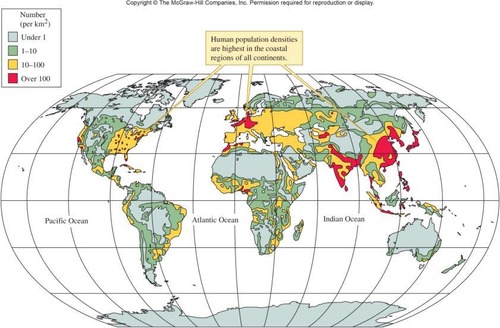

The most efficient approach is to search for manufacturing clusters where underwear production is concentrated. China's Guangdong Province (particularly Shantou), Bangladesh, Vietnam, and Turkey are major hubs. Google searches with specific keywords like "underwear manufacturer [region]" can help identify potential partners.

When I first entered the underwear manufacturing business, identifying suitable manufacturing partners seemed like finding needles in a haystack. Over time, I realized the value of focusing on established manufacturing clusters where suppliers, skilled workers, and industry knowledge are concentrated.

China has traditionally dominated underwear manufacturing due to its comprehensive supply chain, superior product development capabilities, and reliable infrastructure. In Shantou city alone, where HAVING is based, there are hundreds of specialized underwear factories. This concentration creates efficiencies that are hard to match elsewhere.

However, the manufacturing landscape is evolving rapidly due to geopolitical factors. The U.S. has imposed 20% punitive tariffs on Chinese goods, significantly weakening China's competitive advantage. Many brands now seek alternatives to mitigate risks associated with uncertain trade policies.

Regional Manufacturing Comparison

| Region | Strengths | Challenges |

|---|---|---|

| China (Guangdong) | Complete supply chain, fast development, reliable power, high efficiency | Higher labor costs, tariff issues, geopolitical risks |

| Bangladesh | Lower labor costs, favorable tariff treatment, growing capacity | Limited synthetic materials, longer lead times, compliance requirements |

| Vietnam | Developing skills, intermediate costs, favorable trade agreements | Less developed supply chain, limited technical capabilities |

| Turkey | Proximity to Europe, quality craftsmanship, faster shipping to EU | Higher costs, less capacity for mass production |

At HAVING, we've developed a hybrid approach. We maintain our manufacturing excellence in China while establishing partnerships in Bangladesh through a CMT (Cut-Make-Trim) model. We handle product development and material sourcing in China, then manufacture in Bangladesh to leverage tariff advantages for U.S. and European markets. This approach adds about one month to production timelines but offers significant tariff savings.

Evaluating Quality and Materials: How Do You Ensure Excellence?

I've encountered countless businesses who prioritized low costs only to face customer returns and damaged reputations. Quality assessment must happen before production begins, not after products arrive at your warehouse.

To evaluate a manufacturer's quality, request physical samples for hands-on assessment, examine consistency across multiple pieces, verify material certifications, and ask about quality control processes. The best manufacturers maintain strict multi-point inspection systems and can provide detailed quality reports.

Early in my career, I learned a painful lesson about material quality. A customer ordered 10,000 units of a seamless bra, and we sourced the cheapest nylon fabric available to maximize margins. After just a few washes, the garments lost their shape and developed pilling. That mistake cost us the client and taught me that material quality can never be compromised in underwear manufacturing.

When evaluating a potential manufacturing partner, look beyond the finished samples they show you. Request information about their material sourcing practices, quality testing protocols, and defect rates. A reputable manufacturer should be transparent about these aspects of their operation.

At HAVING, we follow a body-before-fabric philosophy. This means we prioritize how materials interact with the human body rather than simply focusing on aesthetic appeal. This approach has guided our material selection process since our founding.

Key Quality Assessment Points

| Quality Aspect | What to Evaluate |

|---|---|

| Material Quality | Fabric weight consistency, stretch recovery, colorfastness, pilling resistance |

| Construction Quality | Seam strength, stitch consistency, elastic application, bar tack reinforcement |

| Trims & Components | Hook & eye durability, underwire integrity, slider function on adjustable straps |

| Fit Consistency | Size grading accuracy, consistent measurements across production runs |

| Certifications | OEKO-TEX, GOTS, BCI, recycled material verification, compliance documentation |

Material innovations deserve special attention when selecting a manufacturing partner. For example, in 2020, we introduced period panties to Primark, growing from zero to 2 million units annually. This required specialized materials and manufacturing processes that many factories couldn't handle. The ability to innovate with materials often separates exceptional manufacturers from average ones.

Assessing Production Capabilities: Can They Meet Your Demands?

Production capacity sounds straightforward but has hidden complexities I've seen derail countless projects. A factory claiming "100,000 units monthly capacity" might mean 100,000 basic briefs but only 20,000 complex bras.

To accurately assess production capabilities, ask about the manufacturer's experience with your specific product type, their current capacity utilization, typical lead times, and product-specific output rates. Request information about their equipment, especially specialized machines required for underwear construction.

I remember working with a startup lingerie brand that needed relatively small quantities but with complex construction. We found a smaller factory that claimed they could handle the technical requirements, but halfway through production, they admitted they didn't have the specialized machines for proper elastication. The entire production run had to be scrapped, costing months of delays.

When assessing production capabilities, consider both volume and technical expertise. A factory accustomed to producing mass-market basics may struggle with luxury lingerie requiring delicate lace application or precise cup construction. Similarly, a high-end boutique manufacturer might not have systems in place to efficiently handle large-scale orders.

Production Capability Assessment

| Production Aspect | Questions to Ask |

|---|---|

| Equipment | Do they have specialized machinery for underwear (coverstitch, elasticator, molding equipment)? |

| Workforce Skill | How long have their operators worked with underwear products? Do they have specialized training? |

| Product Type Experience | Can they show examples of products similar to yours that they've manufactured? |

| Peak Season Capacity | How do they manage capacity during busy seasons? Do they subcontract? |

| Technical Development | What is their sampling process and timeline? Can they develop technical packages? |

Another crucial factor is the manufacturer's experience with your specific business model. At HAVING, we work with diverse clients from major retailers to DTC startups, and each requires different production approaches. A manufacturer accustomed to serving large off-price retailers might struggle with the sample development and flexible production needed for a direct-to-consumer brand. Similarly, factories that primarily serve fast fashion might not have the quality control standards required for premium department store brands.

Comparing Pricing and Minimum Order Quantities: What's the Real Cost?

I've witnessed businesses make costly mistakes by focusing solely on unit price without understanding the total cost picture. Hidden costs and inflexible order requirements can quickly erase apparent savings from a low quote.

When comparing pricing, request detailed breakdowns showing material costs, labor, overhead, and any additional charges. Understand MOQ requirements at both style and color level, and negotiate progressive pricing tiers as your volume grows. Consider the total landed cost including shipping, duties, and potential quality-related expenses.

One of our clients initially chose a competitor based on a 15% lower quote, only to discover that the competitor charged separate fees for pattern-making, size grading, and sample development. By the time they factored in these costs, plus higher defect rates requiring more quality inspections, their total cost was actually higher than our all-inclusive pricing.

MOQ requirements vary significantly between manufacturers and can be deal-breakers for growing businesses. Many factories advertise their overall MOQ but fail to explain their color and size breakdown requirements. A 1,000 unit MOQ might require 500 pieces per color and 100 pieces per size, which often doesn't align with real-world sales distribution.

Pricing Considerations Beyond Unit Cost

| Cost Component | What to Consider |

|---|---|

| Development Costs | Pattern making, sample production, size grading (may be separate or included) |

| Minimum Order Requirements | Overall MOQ, color minimums, size breakdown requirements |

| Tariffs & Duties | Origin country, applicable trade agreements, potential future changes |

| Payment Terms | Deposit requirements, payment timing, accepted payment methods (L/C options) |

| Quality-Related Costs | Inspection fees, potential returns, reputation damage from quality issues |

The tariff situation has dramatically changed the underwear manufacturing landscape. Until recently, China was the default choice despite slightly higher labor costs because its superior infrastructure, efficient workflows, and complete supply chain yielded better overall value. However, with the U.S. imposing 20% punitive tariffs on Chinese goods, the equation has changed significantly.

At HAVING, we've adapted by establishing a hybrid manufacturing model. We handle design and development in our Chinese facilities, where our technical expertise is strongest, but offer production in Bangladesh for clients concerned about tariffs. This approach allows brands to leverage China's development strengths while accessing Bangladesh's tariff advantages. The trade-off is a slightly longer lead time (about one month additional) due to material transportation between countries.

Checking References and Reviews: Are They Reliable Partners?

I've encountered countless manufacturers with impressive facilities and smooth sales presentations who proved unreliable when production challenges arose. References provide insight into real-world performance that no facility tour can reveal.

Request references from current customers, ideally those with similar product types and business models to yours. Ask about communication responsiveness, problem resolution, on-time delivery performance, and quality consistency. Look for manufacturers with long-term clients, as this often indicates reliability and consistent performance.

Early in my career, I learned this lesson the hard way. A factory with beautiful samples and competitive pricing won our business, but as soon as production began, communication slowed dramatically. Quality issues went unresolved, and they prioritized larger customers over us. Had we checked references thoroughly, we would have discovered this pattern.

Manufacturer reliability becomes especially critical during challenging times. The pandemic exposed vulnerabilities in many supply chains, with some factories closing abruptly or demanding changed payment terms mid-production. Companies with stronger financial foundations generally weathered these disruptions better.

Key Reference Check Questions

| Assessment Area | Questions to Ask References |

|---|---|

| Communication | How responsive are they to emails and calls? Do they provide regular production updates? |

| Timeline Adherence | Do they consistently meet agreed delivery dates? How do they handle delays? |

| Problem Resolution | How do they handle quality issues or mistakes? Do they take responsibility? |

| Business Stability | How long have you worked with them? Have there been any financial concerns? |

| Hidden Costs | Were there any unexpected charges or requirements after production began? |

Looking at a manufacturer's financial stability and business longevity is particularly important. At HAVING, we're proud of our continuous operation since 2011, our ownership of our facilities, and our healthy cash flow position. This stability means we can stand behind our production commitments and take responsibility for any issues that arise. Smaller or financially stretched manufacturers might be unable to absorb the cost of production mistakes, leading to disputes or even business failure.

Establishing Communication and Negotiation: How Do You Build a Productive Relationship?

Poor communication can derail even the most promising manufacturing partnership. I've seen projects fail not because of production issues but because expectations weren't clearly established from the beginning.

Effective manufacturer communication requires clear technical documentation, regular check-ins during production, established escalation procedures for problems, and consideration of language barriers and time zones. The sampling process offers insight into a manufacturer's communication style before large orders are placed.

I remember working with a European client who was frustrated with their previous supplier's communication. The factory would simply say "yes" to every request without clarifying if it was actually feasible. This led to repeated disappointments when the final product didn't match expectations. When they switched to us, they were initially surprised by our questions and occasional "no, but here's an alternative" responses – but ultimately appreciated our honesty.

The sampling process serves as a dress rehearsal for full production and reveals much about how a manufacturer operates. At HAVING, we invest heavily in sampling, sometimes absorbing costs exceeding $30 per bra sample and $15 per underwear sample. This commitment demonstrates our confidence in converting samples to production orders.

Communication Protocol Development

| Communication Element | Best Practice |

|---|---|

| Primary Contact | Establish a single point person on both sides who coordinates all communications |

| Technical Specifications | Use detailed tech packs with measurements, materials, and construction notes |

| Regular Updates | Schedule weekly status calls during production with written follow-up summaries |

| Issue Management | Create a formal process for raising concerns with escalation procedures |

| Cultural Considerations | Understand local holidays, working hours, and communication preferences |

Beyond day-to-day communication, a manufacturer's willingness to innovate and suggest improvements shows their commitment to your success. For example, at HAVING, we identified the growing potential for period underwear and proactively presented this opportunity to Primark. This partnership grew from zero to 2 million units annually, benefiting both parties. This kind of proactive product development comes from maintaining open communication channels and understanding client needs deeply.

Making the Final Decision: How Do You Choose the Right Partner?

After all the research and evaluation, making the final decision still feels daunting. I've seen many businesses frozen by analysis paralysis or rushing into partnerships without proper consideration, both leading to costly mistakes.

The best manufacturing partnerships balance quality, price, reliability, and strategic alignment. Start with small orders to test the relationship before scaling up. Consider geographical diversification to mitigate risks, and prioritize manufacturers with experience serving businesses similar to yours in size and model.

When I reflect on our most successful client relationships, they typically began with modest test orders that allowed both parties to learn each other's processes. One of our largest current clients started with just 5,000 pieces five years ago. As trust developed, orders grew, and we now produce over 500,000 units annually for them across multiple product categories.

The geopolitical landscape has made manufacturing diversification increasingly important. Relying exclusively on one country creates vulnerability to trade disputes, tariff changes, or regional disruptions. At HAVING, we've adapted by establishing our Bangladesh operation while maintaining our core Chinese manufacturing capabilities. This allows our clients to make strategic decisions based on their specific needs for each product line.

Decision Matrix Factors

| Decision Factor | Consideration Weight |

|---|---|

| Product Quality & Consistency | High – directly impacts customer satisfaction and returns |

| Price Competitiveness | Medium to High – affects margins but shouldn't override quality |

| Reliability & Communication | High – critical for planning and inventory management |

| Geographical Considerations | Medium to High – impacts tariffs, shipping times, and political risk |

| Innovation Capability | Medium – important for brands seeking competitive advantage |

The manufacturer's experience with your business model is particularly important. Different types of businesses have distinct requirements, and a factory that excels at serving department store brands might struggle with the flexibility needed for a direct-to-consumer brand. At HAVING, we work with various client types – from importers to DTC brands, retail chains to department stores – each requiring different approaches to pricing, quality standards, compliance, order quantities, and material specifications.

Conclusion

Finding the right underwear manufacturer requires balancing multiple factors including quality, price, geographical considerations, and communication. By clearly defining your needs, thoroughly researching options, evaluating capabilities, and starting with test orders, you can build a successful manufacturing partnership that supports your business growth.