Assurer l'excellence des produits: contrôle de la qualité & Normes de fabrication pour les vêtements de sport & Source de l'usure du yoga?

Les processus de contrôle de la qualité incohérents conduisent à des vêtements de sport que les pilules, perdent la forme ou échouent pendant les séances d'entraînement. De nombreuses entreprises ne découvrent les défauts de la fabrication qu'après que les produits ont atteint les clients, endommageant la réputation de la marque et les rendements croissants.

Un contrôle de qualité efficace pour les vêtements de sport nécessite une approche complète: tests de matériaux avant production, surveillance en ligne pendant l'assemblage, tests de performances standardisés, inspection finale du produit à l'aide des normes AQL et lavage des tests de durabilité pour vérifier les performances au fil du temps.

Pour avoir, nous avons affiné nos processus de contrôle de la qualité grâce à des années d'expérience en fabrication, passant à plus de 30 millions de dollars de ventes annuelles au service de plus de 3 000 magasins. J'ai vu de première main à quel point les protocoles QC sont appropriés faire la différence entre les produits qui ravissent les clients et ceux qui endommagent la réputation de la marque.

Qu'est-ce qui rend le contrôle de la qualité unique pour les vêtements de sport?

Les processus standard des vêtements QC ne sont pas suffisants pour les vêtements de sport. La nature technique de ces produits nécessite des tests spécialisés que de nombreux fabricants ne sont pas équipés pour effectuer.

Le contrôle de la qualité des vêtements de sport doit vérifier à la fois la qualité de la construction et la fonctionnalité de performance. Au-delà de l'inspection standard des vêtements, il nécessite des tests spécialisés pour la récupération de l'étirement, la capacité de déchaînement de l'humidité, la coloration pendant la transpiration, l'opacité sous l'étirement et la durabilité grâce à un lavage et à l'usure répétés.

Lorsque nous avons commencé à fabriquer des vêtements de sport à l'avoir, nous avons rapidement réalisé que nos protocoles standard de vêtements QC étaient insuffisants. Les vêtements de sport combinent des éléments de la mode et des performances techniques, nécessitant une approche hybride de l'assurance qualité.

La double nature de la tension active qc

Le contrôle de la qualité des vêtements de sport doit aborder deux aspects distincts:

1. Qualité de construction de vêtements

Semblable aux vêtements standard, cela comprend:

- Intégrité des coutures et qualité de couture

- Identification des défauts de tissu

- Compliance de spécification de taille

- Application élastique et garniture

- Apparence globale et finition

2. Fonctionnalité de performance

Unique aux vêtements de sport, cela comprend:

- Tests d'étirement et de récupération

- Vérification de la gestion de l'humidité

- Évaluation de l'opacité (en particulier pour les leggings)

- La couleur de la couleur pour transpirer et friction

- Durabilité par le lavage et l'usure

Points de défaillance critiques

Notre expérience de fabrication a identifié plusieurs points de défaillance communs qui nécessitent une attention particulière:

| Point d'échec | Impact | Méthode de détection |

|---|---|---|

| Échec de la couture pendant l'étirement | Retours de produits, dommages à la marque | Test d'étirement au point de défaillance |

| Pilling de tissu | Mauvaise apparence, problèmes de qualité perçus | Test d'abrasion de Martindale |

| Transparence pendant la flexion | Embarras des clients, retour | Test d'opacité d'étirement |

| Saignement des couleurs / décoloration | Insatisfaction des clients | Colordestness au lavage, transpirer, frotter |

Pour un aperçu complet des matériaux et de la technologie des vêtements de sport, visitez notre guide détaillé: Vêts actifs & Technologie des vêtements de yoga & Matériaux: Guide de l'acheteur sur les tissus de performance, construction & Durabilité.

À quoi ressemble un processus QC complet?

De nombreuses entreprises mettent en œuvre des processus de contrôle de la qualité incomplets qui manquent des problèmes critiques. Un système QC vraiment efficace couvre chaque étape, des matières premières au produit fini.

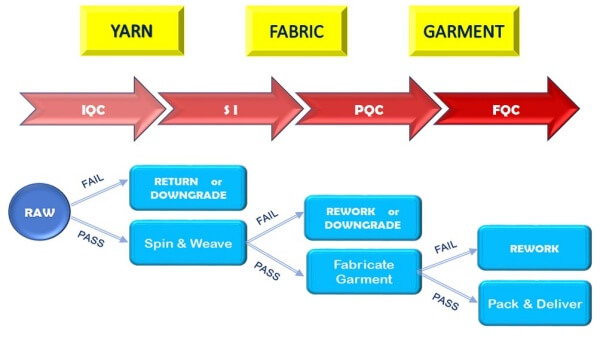

Un processus complet de contrôle de la qualité pour les vêtements de sport comprend cinq étapes clés: les tests de matières premières (vérification des propriétés de performance du tissu), l'approbation de la pré-production (confirmant les méthodes de construction), l'inspection en ligne (problèmes de capture pendant l'assemblage), les tests finaux de produits (vérification des métriques de performance) et les tests de fiabilité (assurant la durabilité au fil du temps).

Pour avoir, nous avons développé un processus de contrôle de la qualité en plusieurs étapes qui s'est avéré efficace à grande échelle. Notre approche garantit une qualité cohérente, même si les volumes de production augmentent:

Étape 1: Contrôle de la qualité des matières premières

Avant le début de la production, tous les matériaux subissent des tests rigoureux:

Tests de tissu

- Propriétés physiques: Poids, épaisseur, étirement, récupération

- Propriétés de performance: Wicking, respirabilité, séchage rapide

- Propriétés d'apparence: Consistance des couleurs, uniformité de surface

- Tests de sécurité: Certification Oeko-TEX, dépistage de substances nocives

Vérification des composants

- Élastiques: Étirement et récupération, coloritude, cohérence de la largeur

- Threads: Résistance à la traction, coloration, compatibilité avec le tissu

- Garniture: Durabilité, résistance à la fixation, résistance à la corrosion (pour les composants métalliques)

- Étiquettes / transferts de chaleur: Force d'adhésion, laver la durabilité, confort contre la peau

Étape 2: Approbation de pré-production

Avant la production de masse, nous vérifions les méthodes de construction grâce à l'évaluation des échantillons:

- Vérification de la méthode de construction: Confirmant des types de coutures optimaux pour chaque zone

- Validation d'ajustement: Vérification du dimensionnement sur la gamme pendant le mouvement

- Tests de performance: Vérification des attributs de performance clés sur les échantillons de pré-production

- Évaluation de l'apparence: Évaluation de l'apparence globale, correspondance des couleurs, alignement d'impression

Étape 3: Contrôle de la qualité en ligne

Pendant la production, notre équipe QC effectue des contrôles réguliers:

- Inspection de la première pièce: La vérification des premières pièces répond à toutes les spécifications

- Contrôles d'intervalle réguliers: Examiner les pièces tout au long de la production

- Inspection des points critiques: Se concentrer sur les zones à haut risque (coutures, application élastique)

- Vérification de la mesure: Assurer la cohérence de la taille tout au long de la production

Étape 4: Inspection finale du produit

Les produits terminés subissent une inspection approfondie avant l'expédition:

Inspection basée sur l'AQL

Nous utilisons les normes de niveau de qualité acceptables (AQL) pour déterminer les tailles d'échantillon d'inspection:

- Défauts critiques: 0% acceptable (problèmes de sécurité, défaillances fonctionnelles majeures)

- Défauts majeurs: 1,5-2,5% AQL (défauts visibles, problèmes fonctionnels mineurs)

- Défauts mineurs: 4,0% AQL (problèmes cosmétiques n'affecte pas la fonction)

Tests de performance

Les échantillons aléatoires subissent des tests fonctionnels:

- Étirement et récupération: Assurer que le tissu revient à la forme d'origine

- Test d'opacité: Vérifier la non-transparence pendant l'étirement

- Gestion de l'humidité: Confirmant la capacité de mèche

- Force de construction: Tester les coutures sous stress

Étape 5: Test de fiabilité

Pour garantir des performances à long terme:

- Test de cycle de lavage: Soumettre des échantillons à plusieurs cycles de lavage (généralement 20-30)

- Rétention de performance: Mesurer les attributs clés après le lavage

- Rétention des couleurs: Évaluation de la coloration après un lavage répété

- Stabilité dimensionnelle: Vérifier le retrait ou l'étirement

Pour plus d'informations sur la construction d'une gamme complète de produits de vêtements de sport, visitez notre guide sur CARANT VOTRE collection: un guide B2B sur les vêtements de sport & Styles d'usure de yoga, fonctions & Options matérielles.

Quelles normes de test doivent être appliquées aux vêtements de sport?

Sans protocoles de test standardisés, il est impossible d'évaluer systématiquement la qualité des produits. De nombreuses entreprises manquent de critères de test clairs, conduisant à des évaluations subjectives de la qualité.

Les vêtements de sport doivent être testés en fonction des normes établies: étirement et récupération à l'aide de l'ASTM D2594, de la couleur avec AATCC 15 (transpiration) et AATCC 61 (lavage), une résistance à la coloration via ASTM D4970, gestion de l'humidité via AATCC 195 et tests d'opacité avec des méthodes de transmission de lumière standardisées.

Pour avoir, nous appliquons des protocoles de test standard pour assurer une évaluation de la qualité objective. Voici les normes clés que nous utilisons:

Normes de test des performances

Étirement et récupération

- ASTM D2594: Méthode d'essai standard pour les propriétés d'étirement des tissus tricotés

- Méthode d'essai: Le tissu est étiré à une extension spécifiée et la récupération est mesurée

- Mesures: Pourcentage de récupération après une durée spécifiée

- Exigence typique: Une récupération minimale de 85% après 1 heure

Coloration

-

AATCC 15: La coloration à la transpiration

-

Méthode d'essai: Tissu exposé à une solution de transpiration artificielle

-

Mesures: Changement de couleurs et coloration évaluée sur l'échelle de gris (1-5)

-

Exigence typique: Note minimale de 4

-

AATCC 61: Colordestness to Whitering

-

Méthode d'essai: Simulation de blanchiment accéléré

-

Mesures: Changement de couleur évalué sur l'échelle de gris (1-5)

-

Exigence typique: Note minimale de 4

Résistance à des anciens

- ASTM D4970: Résistance à des collègues et changement de surface

- Méthode d'essai: Martindale ou méthode de Tumble aléatoire

- Mesures: Évaluation visuelle du pilling (1-5)

- Exigence typique: Note minimale de 4 après des cycles spécifiés

Normes de performance fonctionnelles

Gestion de l'humidité

- AATCC 195: Propriétés de gestion de l'humidité liquide des tissus textiles

- Méthode d'essai: Mesures l'écart et le transport de l'humidité liquide

- Mesures: Plusieurs indices, y compris le temps de mouillage, la vitesse de propagation

- Exigence typique: Varie selon l'utilisation prévue (normes plus élevées pour les activités de haute intensité)

Test d'opacité

- Méthode de transmission légère

- Méthode d'essai: Mesurer la lumière passant par le tissu étiré

- Mesures: Pourcentage de lumière bloquée

- Exigence typique: Minimum de 85 à 90% d'opacité lorsqu'il est étiré pour l'usure du yoga

Normes de durabilité

-

ASTM D4966: Résistance à l'abrasion (méthode Martindale)

-

Méthode d'essai: Tissu frotté contre abradant standard

-

Mesures: Changement d'apparence après des cycles spécifiés

-

Exigence typique: Minimum 10 000 cycles avant un changement significatif

-

AATCC 135: Modifications dimensionnelles dans le lavage automatique

-

Méthode d'essai: Mesures le retrait après le lavage

-

Mesures: Changement en pourcentage des dimensions

-

Exigence typique: Changement maximal de 3 à 5%

Normes de test de sécurité

-

Standard Oeko-Tex 100: Tester des substances nocives

-

Méthode d'essai: Analyse chimique complète

-

Exigence: Certification à la classe de produits appropriée

-

CPSIA Compliance (pour les vêtements de sport pour enfants)

-

Méthode d'essai: Tester le plomb et les phtalates

-

Exigence: Respecter les normes de sécurité fédérales

Pour des informations détaillées sur les matériaux de vêtements de sport et les techniques de construction, visitez notre guide complet sur Vêts actifs & Technologie des vêtements de yoga & Matériaux: Guide de l'acheteur sur les tissus de performance, construction & Durabilité.

Comment évaluez-vous les capacités de contrôle de la qualité d'un fabricant?

De nombreuses entreprises sélectionnent des partenaires de fabrication basés principalement sur le prix, uniquement pour découvrir des problèmes de qualité après la production. Évaluer correctement les capacités de QC avant le partenariat essentiel.

Lors de l'évaluation des capacités de contrôle de la qualité d'un fabricant pour les vêtements de sport, évaluez son équipement de test (appareil de test de stretch, tests de couleur, mesure de l'opacité), dotation en dotant QC (équipe QC dédiée avec expertise en vêtements de sport), procédures documentées (protocoles de test standardisés) et échéance (expérience avec des produits de performance similaires et références à partir de clients existants).

Pour avoir, nous encourageons les partenaires potentiels à évaluer soigneusement nos capacités de contrôle de la qualité avant de nous engager dans la production. Sur la base de notre expérience, voici les facteurs clés à évaluer lors de l'évaluation d'un fabricant:

Infrastructure essentielle de contrôle de la qualité

Équipement de test

Recherchez les fabricants avec:

- Équipement de test de performance du tissu

- Appareil de test de couleur

- Outils de mesure de l'étirement et de la récupération

- Configuration des tests d'opacité

- Installations de test de lavage

Capacités de laboratoire

Idéalement, les fabricants devraient avoir:

- Laboratoire de test interne

- Équipement de mesure calibré

- Matériaux de test standard

- Systèmes de documentation

- Ou des relations établies avec des laboratoires de tests tiers

Personnel de contrôle de la qualité

Évaluez l'équipe QC:

- Personnel dédié au contrôle de la qualité (pas seulement les travailleurs de la production)

- Gestionnaire QC avec une expérience pertinente dans les vêtements de performance

- Programmes de formation du personnel

- Connaissance technique des exigences de vêtements de sport

- Ratio du personnel QC au volume de production

Documentation et procédures

Demande et révision:

- Procédures QC écrites spécifiques aux vêtements de sport

- Tester les protocoles pour les attributs de performance

- Directives de classification des défauts

- Plans d'échantillonnage basés sur les normes AQL

- Systèmes de tenue de registres

- Procédures de traçabilité

Antécédents et expérience

Évaluer les antécédents du fabricant:

- Expérience avec des produits de performance similaires

- Références des clients (en particulier les marques de vêtements de sport)

- Cohérence de la qualité des échantillons

- Exemples de résolution des problèmes

- Initiatives d'amélioration continue

Liste de contrôle d'évaluation sur place

Lorsque vous visitez les fabricants potentiels, observez:

| Zone à évaluer | Que rechercher |

|---|---|

| Plancher de production | Propre, organisation, éclairage, équipement spécialisé pour les vêtements de sport (machines à plat, couverture) |

| Zone de contrôle de la qualité | Espace dédié, bon éclairage, équipement de test, échantillons de référence |

| Points d'inspection | Points de contrôle de qualité visible tout au long de la production, pas seulement l'inspection finale |

| Stockage de matériaux | Système d'étiquetage des matériaux propres, organisé, organisé, contrôlé par le climat |

| Documentation | Instructions de travail dans les stations, enregistrements de qualité, systèmes de traçabilité |

Pour obtenir des conseils sur l'élaboration de votre propre ligne de vêtements de sport avec des partenaires de fabrication fiables, explorez notre ressource sur Votre marque, votre produit: le guide complet de la marque privée (OEM / ODM) & Fabrication de vêtements de yoga.

Quelles certifications sont importantes pour la fabrication de vêtements de sport?

Naviguer dans le paysage complexe des certifications textiles peut être écrasante. De nombreuses entreprises ne savent pas quelles certifications sont vraiment pertinentes pour les vêtements de sport.

Les certifications clés pour les vêtements de sport incluent Oeko-Tex Standard 100 (s'assurer que les textiles sont exempts de substances nocives), ISO 9001 (systèmes de gestion de la qualité), des audits de conformité sociale comme BSCI ou WRAP (fabrication éthique) et des certifications de durabilité facultative comme BlueSign® (production respectueuse de l'environnement) ou GRS (pour le contenu recyclé).

Pour avoir, nous maintenons plusieurs certifications pour garantir que nos vêtements de sport respectent les normes internationales pour la sécurité, la qualité et la fabrication éthique. Voici ce que vous devez savoir sur les certifications pertinentes:

Certifications de sécurité des produits

Standard Oeko-Tex 100

- Ce qu'il certifie: Textiles testés pour des substances nocives

- Importance: Critique pour les produits avec un contact cutané prolongé

- Test Scope: Tests de substances réglementées et non réglementées

- Validité: Nécessite un renouveau annuel et des tests réguliers

Certification de protection UV (pour les vêtements de sport extérieurs)

- Ce qu'il certifie: La capacité du tissu à bloquer les rayons UV nocifs

- Importance: Pertinent pour l'usure des performances en plein air

- Méthode d'essai: Évaluation UPF (Ultraviolet Protection Factor)

- Norme commune: AS / NZS 4399 ou AATCC 183

Certifications de gestion de la qualité

ISO 9001

- Ce qu'il certifie: Systèmes de gestion de la qualité

- Importance: Démontre une approche systématique de la qualité

- Exigences: Procédures documentées, audits internes, amélioration continue

- Avantage: Réduit le risque d'incohérences de qualité

Certifications de conformité sociale

Business Social Compliance Initiative (BSCI)

- Ce qu'il certifie: Pratiques de travail éthiques et conditions de travail

- Importance: Vérifie la fabrication éthique

- Zones d'audit: Salaire équitable, heures de travail, santé et sécurité, pas de travail des enfants

- Processus: Audits de tiers indépendants

Production Accréditée Responsable Mondiale (WRAP)

- Ce qu'il certifie: Fabrication légale, humaine et éthique

- Importance: Programme de conformité sociale reconnue internationalement

- Domaines de concentration: Pratiques de travail, conditions de travail, responsabilité environnementale

- Niveaux: Différents niveaux de certification basés sur la conformité

Certifications de durabilité (facultatif)

bluesign®

- Ce qu'il certifie: Production textile respectueuse de l'environnement

- Importance: Approche complète de la fabrication durable

- Se concentrer: Sécurité chimique, efficacité des ressources, sécurité des consommateurs

- Avantage: Appelle à des marques soucieuses de l'environnement

Global Recycled Standard (GRS)

- Ce qu'il certifie: Contenu recyclé dans les produits

- Importance: Pertinent pour les vêtements de sport à l'aide du polyester recyclé

- Exigences: Contenu recyclé minimum, chaîne de vérification de la garde

- Avantage: Soutient les allégations de durabilité

Vérification de la certification

Lors de l'évaluation des certifications du fabricant:

- Demander des certificats actuels (non expirés)

- Vérifiez la certification via le site Web de l'organisme émetteur

- Vérifiez la portée de la certification (spécifique aux produits pertinents)

- Renseignez-vous sur les procédures de maintenance de certification

Pour les informations du marché et les préférences des consommateurs concernant les produits certifiés, visitez notre analyse de Comprendre les vêtements actifs & Marché des vêtements de yoga: tendances, démographie & Opportunités pour les acheteurs B2B.

Comment assurez-vous une qualité cohérente à grande échelle?

Le maintien de la cohérence de la qualité lors de la mise à l'échelle de la production est un défi commun. De nombreux fabricants ont du mal à offrir le même niveau de qualité lorsqu'ils passent des petites commandes à de grandes séries de production.

Assurer une qualité cohérente à grande échelle nécessite des processus standardisés (procédures documentées pour toutes les étapes de production), une formation complète (garantir que tous les travailleurs comprennent les normes de qualité), le contrôle de la qualité statistique (en utilisant des données pour identifier et traiter les variations) et des systèmes d'amélioration continus (examinant régulièrement et améliorer les processus basés sur les résultats).

Pour avoir, nous avons réussi à mettre à l'échelle notre production de vêtements de sport à plus de 30 millions de dollars de ventes annuelles tout en conservant une qualité constante. Voici nos stratégies clés pour la cohérence de la qualité à grande échelle:

Standardisation et documentation

Le fondement de la qualité cohérente est des processus standardisés:

- Instructions de travail détaillées: Procédures étape par étape pour chaque opération

- Normes visuelles: Exemples physiques de qualité acceptable et inacceptable

- Spécifications de mesure: Des tolérances précises pour toutes les dimensions

- Normes de construction: Exigences spécifiques pour les coutures, les points de suture et les techniques

Formation et développement des compétences

La compétence des travailleurs a un impact significatif sur la cohérence de la qualité:

- Formation initiale complète: Intégration approfondie pour les nouveaux travailleurs

- Certification des compétences: Vérification des compétences avant le travail indépendant

- Développement des compétences en cours: Mises à jour et améliorations de la formation régulières

- Dingue: Développer une polyvalence pour maintenir la flexibilité

Contrôle des processus statistiques

La gestion de la qualité axée sur les données permet la cohérence à l'échelle:

- Mesures en cours: Vérification régulière des dimensions clés

- Suivi des défauts: Surveillance des types et des fréquences des problèmes de qualité

- Analyse des causes profondes: Identifier les causes sous-jacentes des problèmes récurrents

- Implémentation d'action corrective: Approche systématique pour résoudre les problèmes

Technologie et automatisation

L'utilisation stratégique de la technologie améliore la cohérence:

- Coupe automatisée: Assurer une coupe précise de motifs

- Couture à contrôles contrôlés par ordinateur: Maintenir une qualité de couture cohérente

- Inspection de la qualité numérique: Utiliser la technologie pour détecter les défauts

- Suivi RFID: Surveiller les produits tout au long de la production

Pour plus d'informations sur la navigation sur la chaîne d'approvisionnement et les considérations logistiques, visitez notre guide sur De l'usine à l'entrepôt: comprendre les MOQ, délais de plomb & Logistique dans les vêtements actifs & Source de l'usure de yoga.

Conclusion

La mise en œuvre d'un contrôle de qualité robuste et de l'adhésion aux normes de fabrication est essentielle pour une source de vêtements de sport réussie. En comprenant les exigences de test uniques, en établissant des processus de CQ complets et en s'associant à des fabricants correctement certifiés, les entreprises peuvent s'assurer que leurs produits offrent des performances cohérentes et renforcent la confiance des consommateurs.

Pour avoir, notre engagement envers le contrôle de la qualité nous a permis de mettre à l'échelle la production de vêtements de sport tout en maintenant l'excellence, aidant nos partenaires à créer des marques réussies dans cette catégorie compétitive.

Pour un aperçu complet de l'ensemble de la catégorie des vêtements de sport, y compris les tendances du marché et les opportunités commerciales, visitez notre Guide ultime B2B de l'approvisionnement & Vendre des vêtements de sport & Usure de yoga.

Questions fréquemment posées (FAQ)

Quel est le problème de qualité le plus courant dans la fabrication de vêtements de sport?

Les problèmes de qualité les plus courants sont les pilulations (fuzzing de surface qui affectent l'apparence), la défaillance des coutures pendant l'étirement (en particulier dans les zones à stress élevé) et les problèmes d'opacité dans les leggings (devenant transparent lorsqu'ils sont étirés). Tous peuvent être empêchés par la sélection des matériaux et les techniques de construction appropriées.

À quelle fréquence les vêtements de sport doivent-ils être testés pendant la production?

Des vérifications de qualité devraient se produire à plusieurs étapes: approbation de pré-production, inspection de première pièce, vérification en ligne à intervalles réguliers (généralement toutes les 1 à 2 heures) et une inspection finale AQL avant l'expédition. Les tests de performance doivent être effectués sur des échantillons de chaque terrain de production.

Quelle est la différence entre les tests de premier parti et des tests tiers?

Les tests de première partie sont effectués par le fabricant, tandis que les tests tiers sont effectués par des laboratoires indépendants. Les tests tiers offrent une plus grande objectivité et sont souvent nécessaires pour la certification ou la vérification de la conformité.

Comment puis-je vérifier les réclamations de qualité d'un fabricant?

Demander des rapports de test, visiter les installations pour observer les procédures de test, demander des références de clients et commander des échantillons pour des tests indépendants. Envisagez de commencer par une petite production pour vérifier la qualité avant des engagements plus importants.

Quel est le taux de récupération minimum acceptable pour les tissus de vêtements de sport?

Des vêtements de sport de qualité devraient maintenir au moins 85% de récupération après avoir été étiré à 150% des dimensions d'origine. Les produits premium obtiennent souvent une récupération de 90 à 95%, garantissant qu'ils maintiennent la forme grâce à plusieurs vêtements et lavages.

Comment établir des normes de qualité pour ma ligne de vêtements de sport?

Définissez des spécifications claires pour les attributs de performance (étirement, récupération, gestion de l'humidité), normes d'apparence (variations acceptables de la couleur, de la construction) et des exigences de durabilité (cycles de lavage, résistance à l'abrasion). Documentez-les dans un pack technologique complet et établissez des protocoles de test pour vérifier la conformité.

Obtenez un devis gratuit pour vos projets de vêtements de sport