Asegurar la excelencia del producto: control de calidad & Estándares de fabricación para ropa activa & ¿Abastecimiento de desgaste de yoga?

Los procesos de control de calidad inconsistentes conducen a ropa activa que las píldoras, pierden forma o falla durante los entrenamientos. Muchas empresas descubren defectos de fabricación solo después de que los productos llegan a los clientes, dañando la reputación de la marca y el aumento de los rendimientos.

El control de calidad efectivo para la ropa activa requiere un enfoque integral: pruebas de material antes de la producción, el monitoreo en línea durante el ensamblaje, las pruebas de rendimiento estandarizadas, la inspección final del producto utilizando estándares AQL y pruebas de durabilidad de lavado para verificar el rendimiento con el tiempo.

Al tener, hemos refinado nuestros procesos de control de calidad a través de años de experiencia en fabricación, ampliando más de $ 30 millones en ventas anuales que atienden a más de 3,000 tiendas. He visto de primera mano cómo los protocolos de control de calidad adecuados pueden marcar la diferencia entre los productos que deleitan a los clientes y aquellos que dañan la reputación de la marca.

¿Qué hace que el control de calidad sea único para ropa activa?

Los procesos de control de control de indumentaria estándar no son suficientes para la ropa activa. La naturaleza técnica de estos productos requiere pruebas especializadas para las que muchos fabricantes no están equipados para realizar.

El control de calidad de ropa activa debe verificar tanto la calidad de la construcción como la funcionalidad de rendimiento. Más allá de la inspección estándar de la prenda, requiere pruebas especializadas para la recuperación del estiramiento, la capacidad de absorción de la humedad, la solidez de los colores durante la sudoración, la opacidad bajo estiramiento y durabilidad a través del lavado y el desgaste repetidos.

Cuando comenzamos a fabricar ropa activa para tener, nos dimos cuenta rápidamente de que nuestros protocolos de control de control de ropa estándar eran insuficientes. ActiveWear combina elementos de moda y rendimiento técnico, que requieren un enfoque híbrido para el aseguramiento de la calidad.

La naturaleza dual de ActiveWear QC

El control de calidad de ropa activa debe abordar dos aspectos distintos:

1. Calidad de construcción de prendas

Similar a la ropa estándar, esto incluye:

- Integridad de costura y calidad de costura

- Identificación de defectos de tela

- Cumplimiento de la especificación de tamaño

- Aplicación elástica y de recorte

- Apariencia general y acabado

2. Funcionalidad de rendimiento

Exclusivo de la ropa activa, esto incluye:

- Pruebas de estiramiento y recuperación

- Verificación de gestión de humedad

- Evaluación de la opacidad (especialmente para leggings)

- Color Suwer y fricción

- Durabilidad a través del lavado y el desgaste

Puntos de falla críticos

Nuestra experiencia de fabricación ha identificado varios puntos de falla comunes que requieren atención especial:

| Punto de falla | Impacto | Método de detección |

|---|---|---|

| Falla de la costura durante el estiramiento | Devoluciones de productos, daño a la marca | Prueba de estiramiento hasta el punto de falla |

| Píldora de tela | Mala apariencia, problemas de calidad percibidos | Prueba de abrasión de Martindale |

| Transparencia durante la flexión | Vergüenza del cliente, devoluciones | Prueba de opacidad de estiramiento |

| Sangrado de color/desvanecimiento | Insatisfacción del cliente | Colorimedad al lavado, sudor, frotar |

Para obtener una descripción completa de los materiales y la tecnología de ropa activa, visite nuestra guía detallada: Ropa activa & Tecnología de desgaste de yoga & Materiales: una guía del comprador para telas de rendimiento, construcción & Durabilidad.

¿Cómo es un proceso de CC integral?

Muchas empresas implementan procesos de control de calidad incompletos que pierden problemas críticos. Un sistema de CC verdaderamente efectivo cubre todas las etapas, desde materias primas hasta productos terminados.

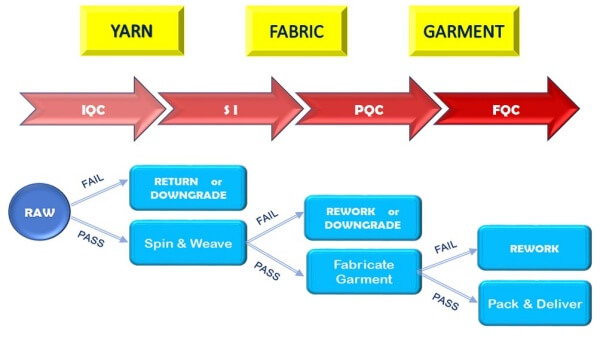

Un proceso integral de control de calidad para ropa activa incluye cinco etapas clave: pruebas de materia prima (verificación de propiedades de rendimiento de la tela), aprobación de preproducción (confirmación de métodos de construcción), inspección en línea (problemas de captura durante el ensamblaje), pruebas finales de productos (verificación de métricas de rendimiento) y pruebas de confiabilidad (que garantiza la durabilidad a lo largo del tiempo).

Al tener, hemos desarrollado un proceso de control de calidad de varias etapas que ha demostrado ser efectivo a escala. Nuestro enfoque garantiza una calidad consistente incluso a medida que aumentan los volúmenes de producción:

Etapa 1: Control de calidad de materia prima

Antes de que comience la producción, todos los materiales experimentan pruebas rigurosas:

Prueba de tela

- Propiedades físicas: Peso, grosor, estiramiento, recuperación

- Propiedades de rendimiento: Wicking, transpirabilidad, secado rápido

- Propiedades de apariencia: Consistencia del color, uniformidad superficial

- Prueba de seguridad: Certificación Oeko-Tex, detección de sustancias dañinas

Verificación de componentes

- Elásticos: Estiramiento y recuperación, rango de colores, consistencia de ancho

- Trapos: Resistencia a la tracción, placa de colores, compatibilidad con la tela

- Adornos: Durabilidad, resistencia a la unión, resistencia a la corrosión (para componentes metálicos)

- Etiquetas/transferencias de calor: Fuerza de adhesión, durabilidad de lavado, comodidad contra la piel

Etapa 2: aprobación de preproducción

Antes de la producción en masa, verificamos los métodos de construcción a través de la evaluación de la muestra:

- Verificación del método de construcción: Confirmar tipos de costuras óptimas para cada área

- Validación de ajuste: Verificación de dimensiones en el rango durante el movimiento

- Prueba de rendimiento: Verificar los atributos clave de rendimiento en las muestras de preproducción

- Evaluación de apariencia: Evaluar el aspecto general, la coincidencia de color, la alineación de la impresión

Etapa 3: control de calidad en línea

Durante la producción, nuestro equipo de CC realiza controles regulares:

- Inspección de primera pieza: Verificar las primeras piezas cumplen con todas las especificaciones

- Verificaciones de intervalos regulares: Examinar piezas a lo largo de la producción

- Inspección de puntos críticos: Centrarse en áreas de alto riesgo (costuras, aplicación elástica)

- Verificación de medición: Asegurar la consistencia del tamaño durante la producción

Etapa 4: Inspección final del producto

Los productos completados experimentan una inspección exhaustiva antes del envío:

Inspección basada en AQL

Utilizamos estándares de nivel de calidad aceptables (AQL) para determinar los tamaños de muestra de inspección:

- Defectos críticos: 0% aceptable (problemas de seguridad, fallas funcionales importantes)

- Defectos importantes: 1.5-2.5% AQL (defectos visibles, problemas funcionales menores)

- Defectos menores: 4.0% AQL (problemas cosméticos que no afectan la función)

Prueba de rendimiento

Las muestras aleatorias experimentan pruebas funcionales:

- Estiramiento y recuperación: Asegurar que la tela vuelva a la forma original

- Prueba de opacidad: Verificar la no transparencia durante el estiramiento

- Gestión de humedad: Confirmando la capacidad de absorción

- Fuerza de construcción: Prueba de costuras bajo estrés

Etapa 5: Prueba de confiabilidad

Para garantizar el rendimiento a largo plazo:

- Prueba de ciclo de lavado: Sometiendo muestras a múltiples ciclos de lavado (típicamente 20-30)

- Retención de rendimiento: Medición de atributos clave después de lavar

- Retención de color: Evaluación de la solidez de color después de un lavado repetido

- Estabilidad dimensional: Comprobación de contracción o estiramiento

Para obtener información sobre la construcción de una línea completa de productos de ropa activa, visite nuestra guía sobre Curación de su colección: una guía B2B para ropa activa & Estilos de ropa de yoga, funciones & Opciones de material.

¿Qué estándares de prueba deben aplicarse a la ropa activa?

Sin protocolos de prueba estandarizados, es imposible evaluar constantemente la calidad del producto. Muchas empresas carecen de criterios de prueba claros, lo que lleva a evaluaciones de calidad subjetivas.

La ropa activa debe probarse de acuerdo con los estándares establecidos: estiramiento y recuperación utilizando ASTM D2594, la rentabilidad del color con AATCC 15 (transpiración) y AATCC 61 (lavado), resistencia de la piloto a través de ASTM D4970, la gestión de la humedad a través de AATCC 195 y las pruebas de opacidad con métodos de transmisión de luz estandarizados.

Al tener, aplicamos protocolos de prueba estándar de la industria para garantizar la evaluación de calidad de objetivos. Estos son los estándares clave que utilizamos:

Estándares de prueba de rendimiento

Estiramiento y recuperación

- ASTM D2594: Método de prueba estándar para propiedades de estiramiento de telas tejidas

- Método de prueba: La tela se estira a una extensión especificada y se mide la recuperación

- Medición: Porcentaje de recuperación después del tiempo especificado

- Requisito típico: Mínimo 85% de recuperación después de 1 hora

Decretización de colores

-

AATCC 15: Color Fastness a la transpiración

-

Método de prueba: Tela expuesta a la solución de transpiración artificial

-

Medición: Cambio de color y manchas clasificadas en escala de grises (1-5)

-

Requisito típico: Calificación mínima de 4

-

AATCC 61: Color Fastness para el lavado

-

Método de prueba: Simulación de lavado acelerada

-

Medición: Cambio de color calificado en escala de grises (1-5)

-

Requisito típico: Calificación mínima de 4

Resistencia de pilas

- ASTM D4970: Resistencia de la pillada y cambio de superficie

- Método de prueba: Martindale o método de caída aleatoria

- Medición: Calificación visual de pilling (1-5)

- Requisito típico: Calificación mínima de 4 después de los ciclos especificados

Estándares de rendimiento funcionales

Gestión de humedad

- AATCC 195: Propiedades de gestión de humedad líquida de las telas textiles

- Método de prueba: Medidas de propagación y transporte de humedad líquida

- Medición: Múltiples índices, incluyendo tiempo de humectación, velocidad de extensión

- Requisito típico: Varía por uso previsto (estándares más altos para actividades de alta intensidad)

Prueba de opacidad

- Método de transmisión de luz

- Método de prueba: Medir la luz que pasa a través de la tela estirada

- Medición: Porcentaje de luz bloqueado

- Requisito típico: Mínimo 85-90% de opacidad cuando se estira para el desgaste de yoga

Estándares de durabilidad

-

ASTM D4966: Resistencia a la abrasión (método Martindale)

-

Método de prueba: Tela frotada contra abdominales estándar

-

Medición: Cambio de apariencia después de ciclos especificados

-

Requisito típico: Mínimo 10,000 ciclos antes de un cambio significativo

-

AATCC 135: Cambios dimensionales en el lavado automático

-

Método de prueba: Medidas encogimiento después de lavar

-

Medición: Cambio porcentual en las dimensiones

-

Requisito típico: Cambio máximo del 3-5%

Normas de prueba de seguridad

-

OEKO-TEX Standard 100: Pruebas de sustancias dañinas

-

Método de prueba: Análisis químico integral

-

Requisito: Certificación a la clase de producto apropiada

-

Cumplimiento de la CPSIA (para ropa activa de los niños)

-

Método de prueba: Pruebas de plomo y ftalatos

-

Requisito: Reunión de estándares federales de seguridad

Para obtener información detallada sobre materiales de ropa activa y técnicas de construcción, visite nuestra guía integral sobre Ropa activa & Tecnología de desgaste de yoga & Materiales: una guía del comprador para telas de rendimiento, construcción & Durabilidad.

¿Cómo evalúa las capacidades de control de calidad de un fabricante?

Muchas empresas seleccionan socios de fabricación basados principalmente en el precio, solo para descubrir problemas de calidad después de la producción. Evaluar adecuadamente las capacidades de CC antes de la asociación es esencial.

Al evaluar las capacidades de control de calidad de un fabricante para la ropa activa, evalúe sus equipos de prueba (aparatos de prueba de estiramiento, pruebas de colores, medición de opacidad), personal de CC (equipo de QC dedicado con experiencia en ropa activa), procedimientos documentados (protocolos de pruebas estandarizadas) y rastrear (experiencia con productos de rendimiento similares y referencias de clientes existentes).

Al tener, alentamos a los socios potenciales a evaluar a fondo nuestras capacidades de control de calidad antes de comprometerse con la producción. Según nuestra experiencia, aquí están los factores clave para evaluar al evaluar a un fabricante:

Infraestructura de control de calidad esencial

Equipo de prueba

Busque fabricantes con:

- Equipo de prueba de rendimiento de la tela

- Aparato de prueba de colores.

- Herramientas de medición de estiramiento y recuperación

- Configuración de pruebas de opacidad

- Instalaciones de prueba de lavado

Capacidades de laboratorio

Idealmente, los fabricantes deben tener:

- Laboratorio de prueba interno

- Equipo de medición calibrado

- Materiales de prueba estándar

- Sistemas de documentación

- O relaciones establecidas con laboratorios de pruebas de terceros

Personal de control de calidad

Evaluar el equipo de control de calidad:

- Personal de control de calidad dedicado (no solo trabajadores de producción)

- Gerente de QC con experiencia relevante en ropa de rendimiento

- Programas de capacitación del personal

- Conocimiento técnico de los requisitos de ropa activa

- Relación del personal de control de calidad y volumen de producción

Documentación y procedimientos

Solicitar y revisar:

- Procedimientos de control de calidad escritos específicos para ropa activa

- Protocolos de prueba para atributos de rendimiento

- Pautas de clasificación de defectos

- Planes de muestreo basados en estándares de AQL

- Sistemas de mantenimiento de registros

- Procedimientos de trazabilidad

Rastreo y experiencia

Evaluar el historial del fabricante:

- Experiencia con productos de rendimiento similares

- Referencias del cliente (particularmente las marcas de ropa activa)

- Muestra de consistencia de calidad

- Ejemplos de resolución de problemas

- Iniciativas de mejora continua

Lista de verificación de evaluación en el sitio

Al visitar potenciales fabricantes, observe:

| Área para evaluar | Que buscar |

|---|---|

| Piso de producción | Limpieza, organización, iluminación, equipo especializado para ropa activa (máquinas plana, costa) |

| Área de control de calidad | Espacio dedicado, buena iluminación, equipo de prueba, muestras de referencia |

| Puntos de inspección | Puntos de control de calidad visible durante la producción, no solo la inspección final |

| Almacenamiento de materiales | Sistema de etiquetado de material limpio, organizado, controlado con clima |

| Documentación | Instrucciones de trabajo en estaciones, registros de calidad, sistemas de trazabilidad |

Para obtener orientación sobre el desarrollo de su propia línea de ropa activa con socios de fabricación confiables, explore nuestro recurso en Su marca, su producto: The ActiveWear de la Guía completa de la etiqueta privada (OEM/ODM) & Fabricación de ropa de yoga.

¿Qué certificaciones son importantes para la fabricación de ropa activa?

Navegar por el complejo panorama de las certificaciones textiles puede ser abrumador. Muchas empresas no son conscientes de qué certificaciones son realmente relevantes para la ropa de activo.

Las certificaciones clave para ropa activa incluyen Oeko-Tex Standard 100 (garantizar que los textiles estén libres de sustancias dañinas), ISO 9001 (sistemas de gestión de calidad), auditorías de cumplimiento social como BSCi o WRAP (fabricación ética) y certificaciones de sostenibilidad opcionales como Bluesign® (producción ambientalmente amigable) o GRS (para contenido recipido).

Al tener, mantenemos múltiples certificaciones para garantizar que nuestra ropa activa cumpla con los estándares internacionales de seguridad, calidad y fabricación ética. Esto es lo que debe saber sobre las certificaciones relevantes:

Certificaciones de seguridad del producto

OEKO-TEX Standard 100

- Que certifica: Textiles probados para sustancias dañinas

- Importancia: Crítico para productos con contacto cutáneo prolongado

- Alcance de prueba: Pruebas de sustancias reguladas y no reguladas

- Validez: Requiere renovación anual y pruebas regulares

Certificación de protección UV (para ropa activa al aire libre)

- Que certifica: La capacidad de la tela para bloquear los rayos UV dañinos

- Importancia: Relevante para el desgaste de rendimiento al aire libre

- Método de prueba: Calificación UPF (factor de protección ultravioleta)

- Estándar común: AS/NZS 4399 o AATCC 183

Certificaciones de gestión de calidad

ISO 9001

- Que certifica: Sistemas de gestión de calidad

- Importancia: Demuestra un enfoque sistemático para la calidad

- Requisitos: Procedimientos documentados, auditorías internas, mejora continua

- Beneficio: Reduce el riesgo de inconsistencias de calidad

Certificaciones de cumplimiento social

Iniciativa de cumplimiento social empresarial (BSCI)

- Que certifica: Prácticas laborales éticas y condiciones de trabajo

- Importancia: Verifica la fabricación ética

- Áreas de auditoría: Salarios justos, horas de trabajo, salud y seguridad, sin mano de obra infantil

- Proceso: Auditorías independientes de terceros

Producción Acreditada Responsable Mundial (WRAP)

- Que certifica: Fabricación legal, humana y ética

- Importancia: Programa de cumplimiento social reconocido internacionalmente

- Áreas de enfoque: Prácticas laborales, condiciones laborales, responsabilidad ambiental

- Nivel: Diferentes niveles de certificación basados en el cumplimiento

Certificaciones de sostenibilidad (opcional)

Bluesign®

- Que certifica: Producción textil amigable con el medio ambiente

- Importancia: Enfoque integral para la fabricación sostenible

- Enfocar: Seguridad química, eficiencia de recursos, seguridad del consumidor

- Beneficio: Apela a las marcas conscientes del medio ambiente

Estándar reciclado global (GRS)

- Que certifica: Contenido reciclado en productos

- Importancia: Relevante para ropa activa utilizando poliéster reciclado

- Requisitos: Contenido reciclado mínimo, verificación de la cadena de custodia

- Beneficio: Apoya las reclamaciones de sostenibilidad

Verificación de certificación

Al evaluar las certificaciones del fabricante:

- Solicitar certificados actuales (no caducado)

- Verificar la certificación a través del sitio web del organismo emisor

- Verifique el alcance de la certificación (específico de los productos relevantes)

- Pregunte sobre los procedimientos de mantenimiento de la certificación

Para las ideas del mercado y las preferencias del consumidor con respecto a los productos certificados, visite nuestro análisis de Comprender la ropa activa & Mercado de ropa de yoga: tendencias, demografía & Oportunidades para compradores B2B.

¿Cómo se asegura una calidad consistente a escala?

Mantener la consistencia de calidad al escalar la producción es un desafío común. Muchos fabricantes luchan por ofrecer el mismo nivel de calidad al pasar de pedidos pequeños a grandes ejecuciones de producción.

Asegurar una calidad consistente a escala requiere procesos estandarizados (procedimientos documentados para todos los pasos de producción), capacitación integral (asegurando que todos los trabajadores comprendan los estándares de calidad), control de calidad estadística (utilizando datos para identificar y abordar variaciones) y sistemas de mejora continua (revisando y mejorando regularmente los procesos basados en los hallazgos).

Al tener, hemos escalado con éxito nuestra producción de ropa activa a más de $ 30 millones en ventas anuales al tiempo que mantenemos una calidad consistente. Estas son nuestras estrategias clave para la consistencia de calidad a escala:

Estandarización y documentación

La base de la calidad consistente es procesos estandarizados:

- Instrucciones de trabajo detalladas: Procedimientos paso a paso para cada operación

- Estándares visuales: Ejemplos físicos de calidad aceptable e inaceptable

- Especificaciones de medición: Tolerancias precisas para todas las dimensiones

- Estándares de construcción: Requisitos específicos para costuras, puntadas y técnicas

Capacitación y desarrollo de habilidades

La habilidad del trabajador afecta significativamente la consistencia de calidad:

- Entrenamiento inicial integral: Incorporación completa para nuevos trabajadores

- Certificación de habilidades: Verificación de competencia antes del trabajo independiente

- Desarrollo de habilidades continuas: Actualizaciones y mejoras de capacitación regulares

- Entrenamiento cruzado: Desarratando la versatilidad para mantener la flexibilidad

Control de procesos estadísticos

La gestión de calidad basada en datos permite la consistencia a escala:

- Medidas en proceso: Verificación regular de dimensiones clave

- Seguimiento de defectos: Tipos de monitoreo y frecuencias de problemas de calidad

- Análisis de causa raíz: Identificar causas subyacentes de problemas recurrentes

- Implementación de acción correctiva: Enfoque sistemático para resolver problemas

Tecnología y automatización

El uso estratégico de la tecnología mejora la consistencia:

- Corte automatizado: Asegurar el corte de patrones precisos

- Costura controlada por computadora: Mantener una calidad de costura consistente

- Inspección de calidad digital: Uso de la tecnología para detectar defectos

- Seguimiento de RFID: Monitoreo de productos a lo largo de la producción

Para obtener información sobre la navegación de la cadena de suministro y las consideraciones de logística, visite nuestra guía sobre De la fábrica al almacén: comprensión de los MOQ, los tiempos de entrega & Logística en ropa activa & Abastecimiento de ropa de yoga.

Conclusión

La implementación de un control de calidad robusto y la adherencia a los estándares de fabricación son esenciales para un abastecimiento exitoso de ropa activa. Al comprender los requisitos de prueba únicos, establecer procesos integrales de control de calidad y asociarse con fabricantes correctamente certificados, las empresas pueden garantizar que sus productos ofrecen un rendimiento constante y generar confianza del consumidor.

Al tener, nuestro compromiso con el control de calidad nos ha permitido escalar la producción de ropa activa mientras mantiene la excelencia, ayudando a nuestros socios a construir marcas exitosas en esta categoría competitiva.

Para obtener una descripción completa de toda la categoría de ropa activa, incluidas las tendencias del mercado y las oportunidades de negocios, visite nuestra Guía Ultimate B2B para el abastecimiento & Vender ropa activa & Ropa de yoga.

Preguntas frecuentes (preguntas frecuentes)

¿Cuál es el problema de calidad más común en la fabricación de ropa activa?

Los problemas de calidad más comunes son la pillada (lucha contra la superficie que afecta la apariencia), la falla de la costura durante el estiramiento (particularmente en las áreas de alto estrés) y los problemas de opacidad en las leggings (que se transmiten cuando se estira). Todo se puede prevenir a través de técnicas adecuadas de selección de materiales y construcción.

¿Con qué frecuencia se debe probar la ropa activa durante la producción?

Los controles de calidad deben ocurrir en múltiples etapas: aprobación de preproducción, inspección de primera pieza, verificaciones en línea a intervalos regulares (generalmente cada 1-2 horas) e inspección final de AQL antes del envío. Las pruebas de rendimiento deben realizarse en muestras de cada lote de producción.

¿Cuál es la diferencia entre las pruebas de terceros y de terceros?

El fabricante realiza pruebas de primera parte, mientras que las pruebas de terceros son realizadas por laboratorios independientes. Las pruebas de terceros proporcionan una mayor objetividad y a menudo se requiere para la certificación o la verificación de cumplimiento.

¿Cómo puedo verificar los reclamos de calidad de un fabricante?

Solicite informes de prueba, visite instalaciones para observar procedimientos de prueba, solicitar referencias de clientes y solicitar muestras para pruebas independientes. Considere comenzar con una pequeña producción de producción para verificar la calidad antes de compromisos más grandes.

¿Cuál es la tasa de recuperación mínima aceptable para las telas de ropa activa?

La ropa activa de calidad debe mantener al menos un 85% de recuperación después de estirarse al 150% de las dimensiones originales. Los productos premium a menudo logran una recuperación del 90-95%, asegurando que mantengan forma a través de múltiples usos y lavados.

¿Cómo establezco estándares de calidad para mi línea de ropa activa?

Definir especificaciones claras para los atributos de rendimiento (estiramiento, recuperación, gestión de la humedad), estándares de apariencia (variaciones aceptables en el color, construcción) y requisitos de durabilidad (ciclos de lavado, resistencia a la abrasión). Documente estos en un paquete tecnológico integral y establezca protocolos de prueba para verificar el cumplimiento.

Obtenga una cotización gratuita para sus proyectos de ropa activa