Ensuring Product Excellence: Quality Control & Manufacturing Standards for Activewear & Yoga Wear Sourcing?

Inconsistent quality control processes lead to activewear that pills, loses shape, or fails during workouts. Many businesses discover manufacturing defects only after products reach customers, damaging brand reputation and increasing returns.

Effective quality control for activewear requires a comprehensive approach: material testing before production, in-line monitoring during assembly, standardized performance testing, final product inspection using AQL standards, and wash durability testing to verify performance over time.

At HAVING, we've refined our quality control processes through years of manufacturing experience, scaling to over $30 million in annual sales serving more than 3,000 stores. I've seen firsthand how proper QC protocols can make the difference between products that delight customers and those that damage brand reputation.

What Makes Quality Control Unique for Activewear?

Standard apparel QC processes aren't sufficient for activewear. The technical nature of these products requires specialized testing that many manufacturers aren't equipped to perform.

Activewear quality control must verify both construction quality and performance functionality. Beyond standard garment inspection, it requires specialized testing for stretch recovery, moisture-wicking capability, colorfastness during sweating, opacity under stretch, and durability through repeated washing and wear.

When we first started manufacturing activewear at HAVING, we quickly realized that our standard apparel QC protocols were insufficient. Activewear combines elements of both fashion and technical performance, requiring a hybrid approach to quality assurance.

The Dual Nature of Activewear QC

Activewear quality control must address two distinct aspects:

1. Garment Construction Quality

Similar to standard apparel, this includes:

- Seam integrity and stitching quality

- Fabric defect identification

- Size specification compliance

- Elastic and trim application

- Overall appearance and finish

2. Performance Functionality

Unique to activewear, this includes:

- Stretch and recovery testing

- Moisture management verification

- Opacity assessment (especially for leggings)

- Colorfastness to sweat and friction

- Durability through washing and wear

Critical Failure Points

Our manufacturing experience has identified several common failure points that require special attention:

| Failure Point | Impact | Detection Method |

|---|---|---|

| Seam failure during stretch | Product returns, brand damage | Stretch testing to failure point |

| Fabric pilling | Poor appearance, perceived quality issues | Martindale abrasion testing |

| Transparency during bending | Customer embarrassment, returns | Stretch opacity testing |

| Color bleeding/fading | Customer dissatisfaction | Colorfastness to washing, sweat, rubbing |

For a comprehensive overview of activewear materials and technology, visit our detailed guide: Activewear & Yoga Wear Technology & Materials: A Buyer's Guide to Performance Fabrics, Construction & Durability.

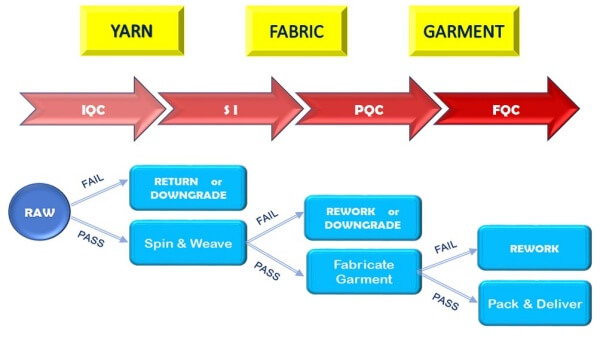

What Does a Comprehensive QC Process Look Like?

Many businesses implement incomplete quality control processes that miss critical issues. A truly effective QC system covers every stage from raw materials to finished product.

A comprehensive quality control process for activewear includes five key stages: raw material testing (verifying fabric performance properties), pre-production approval (confirming construction methods), in-line inspection (catching issues during assembly), final product testing (verifying performance metrics), and reliability testing (ensuring durability over time).

At HAVING, we've developed a multi-stage quality control process that has proven effective at scale. Our approach ensures consistent quality even as production volumes increase:

Stage 1: Raw Material Quality Control

Before production begins, all materials undergo rigorous testing:

Fabric Testing

- Physical Properties: Weight, thickness, stretch, recovery

- Performance Properties: Moisture-wicking, breathability, quick-drying

- Appearance Properties: Color consistency, surface uniformity

- Safety Testing: OEKO-TEX certification, harmful substance screening

Component Verification

- Elastics: Stretch and recovery, colorfastness, width consistency

- Threads: Tensile strength, colorfastness, compatibility with fabric

- Trims: Durability, attachment strength, corrosion resistance (for metal components)

- Labels/Heat Transfers: Adhesion strength, wash durability, comfort against skin

Stage 2: Pre-Production Approval

Before mass production, we verify construction methods through sample evaluation:

- Construction Method Verification: Confirming optimal seam types for each area

- Fit Validation: Checking sizing across the range during movement

- Performance Testing: Verifying key performance attributes on pre-production samples

- Appearance Assessment: Evaluating overall look, color matching, print alignment

Stage 3: In-Line Quality Control

During production, our QC team conducts regular checks:

- First Piece Inspection: Verifying the first pieces meet all specifications

- Regular Interval Checks: Examining pieces throughout the production run

- Critical Point Inspection: Focusing on high-risk areas (seams, elastic application)

- Measurement Verification: Ensuring size consistency throughout production

Stage 4: Final Product Inspection

Completed products undergo thorough inspection before shipping:

AQL-Based Inspection

We use Acceptable Quality Level (AQL) standards to determine inspection sample sizes:

- Critical Defects: 0% acceptable (safety issues, major functional failures)

- Major Defects: 1.5-2.5% AQL (visible defects, minor functional issues)

- Minor Defects: 4.0% AQL (cosmetic issues not affecting function)

Performance Testing

Random samples undergo functional testing:

- Stretch and Recovery: Ensuring fabric returns to original shape

- Opacity Testing: Verifying non-transparency during stretch

- Moisture Management: Confirming wicking capability

- Construction Strength: Testing seams under stress

Stage 5: Reliability Testing

To ensure long-term performance:

- Wash Cycle Testing: Subjecting samples to multiple wash cycles (typically 20-30)

- Performance Retention: Measuring key attributes after washing

- Color Retention: Evaluating colorfastness after repeated washing

- Dimensional Stability: Checking for shrinkage or stretching

For insights on building a complete activewear product line, visit our guide on Curating Your Collection: A B2B Guide to Activewear & Yoga Wear Styles, Functions & Material Options.

What Testing Standards Should Be Applied to Activewear?

Without standardized testing protocols, it's impossible to consistently evaluate product quality. Many businesses lack clear testing criteria, leading to subjective quality assessments.

Activewear should be tested according to established standards: stretch and recovery using ASTM D2594, colorfastness with AATCC 15 (perspiration) and AATCC 61 (washing), pilling resistance via ASTM D4970, moisture management through AATCC 195, and opacity testing with standardized light transmission methods.

At HAVING, we apply industry-standard testing protocols to ensure objective quality assessment. Here are the key standards we use:

Performance Testing Standards

Stretch and Recovery

- ASTM D2594: Standard Test Method for Stretch Properties of Knitted Fabrics

- Test Method: Fabric is stretched to a specified extension and recovery is measured

- Measurement: Percentage of recovery after specified time

- Typical Requirement: Minimum 85% recovery after 1 hour

Colorfastness

-

AATCC 15: Colorfastness to Perspiration

-

Test Method: Fabric exposed to artificial perspiration solution

-

Measurement: Color change and staining rated on gray scale (1-5)

-

Typical Requirement: Minimum rating of 4

-

AATCC 61: Colorfastness to Laundering

-

Test Method: Accelerated laundering simulation

-

Measurement: Color change rated on gray scale (1-5)

-

Typical Requirement: Minimum rating of 4

Pilling Resistance

- ASTM D4970: Pilling Resistance and Surface Change

- Test Method: Martindale or random tumble method

- Measurement: Visual rating of pilling (1-5)

- Typical Requirement: Minimum rating of 4 after specified cycles

Functional Performance Standards

Moisture Management

- AATCC 195: Liquid Moisture Management Properties of Textile Fabrics

- Test Method: Measures spreading and transport of liquid moisture

- Measurement: Multiple indices including wetting time, spreading speed

- Typical Requirement: Varies by intended use (higher standards for high-intensity activities)

Opacity Testing

- Light Transmission Method

- Test Method: Measuring light passing through stretched fabric

- Measurement: Percentage of light blocked

- Typical Requirement: Minimum 85-90% opacity when stretched for yoga wear

Durability Standards

-

ASTM D4966: Abrasion Resistance (Martindale Method)

-

Test Method: Fabric rubbed against standard abradant

-

Measurement: Appearance change after specified cycles

-

Typical Requirement: Minimum 10,000 cycles before significant change

-

AATCC 135: Dimensional Changes in Automatic Washing

-

Test Method: Measures shrinkage after washing

-

Measurement: Percentage change in dimensions

-

Typical Requirement: Maximum 3-5% change

Safety Testing Standards

-

OEKO-TEX Standard 100: Testing for harmful substances

-

Test Method: Comprehensive chemical analysis

-

Requirement: Certification to appropriate product class

-

CPSIA Compliance (for children's activewear)

-

Test Method: Testing for lead and phthalates

-

Requirement: Meeting federal safety standards

For detailed information on activewear materials and construction techniques, visit our comprehensive guide on Activewear & Yoga Wear Technology & Materials: A Buyer's Guide to Performance Fabrics, Construction & Durability.

How Do You Evaluate a Manufacturer's Quality Control Capabilities?

Many businesses select manufacturing partners based primarily on price, only to discover quality issues after production. Properly evaluating QC capabilities before partnership is essential.

When evaluating a manufacturer's quality control capabilities for activewear, assess their testing equipment (stretch testing apparatus, colorfastness testing, opacity measurement), QC staffing (dedicated QC team with activewear expertise), documented procedures (standardized testing protocols), and track record (experience with similar performance products and references from existing clients).

At HAVING, we encourage potential partners to thoroughly evaluate our quality control capabilities before committing to production. Based on our experience, here are the key factors to assess when evaluating a manufacturer:

Essential Quality Control Infrastructure

Testing Equipment

Look for manufacturers with:

- Fabric performance testing equipment

- Colorfastness testing apparatus

- Stretch and recovery measurement tools

- Opacity testing setup

- Wash testing facilities

Laboratory Capabilities

Ideally, manufacturers should have:

- In-house testing lab

- Calibrated measuring equipment

- Standard testing materials

- Documentation systems

- Or established relationships with third-party testing labs

Quality Control Personnel

Evaluate the QC team:

- Dedicated quality control staff (not just production workers)

- QC manager with relevant experience in performance apparel

- Staff training programs

- Technical knowledge of activewear requirements

- Ratio of QC staff to production volume

Documentation and Procedures

Request and review:

- Written QC procedures specific to activewear

- Testing protocols for performance attributes

- Defect classification guidelines

- Sampling plans based on AQL standards

- Record-keeping systems

- Traceability procedures

Track Record and Experience

Assess the manufacturer's history:

- Experience with similar performance products

- Client references (particularly activewear brands)

- Sample quality consistency

- Problem resolution examples

- Continuous improvement initiatives

On-Site Evaluation Checklist

When visiting potential manufacturers, observe:

| Area to Evaluate | What to Look For |

|---|---|

| Production Floor | Cleanliness, organization, lighting, specialized equipment for activewear (flatlock machines, coverstitch) |

| Quality Control Area | Dedicated space, good lighting, testing equipment, reference samples |

| Inspection Points | Visible quality checkpoints throughout production, not just final inspection |

| Material Storage | Clean, organized, climate-controlled, material labeling system |

| Documentation | Work instructions at stations, quality records, traceability systems |

For guidance on developing your own activewear line with reliable manufacturing partners, explore our resource on Your Brand, Your Product: The Complete Guide to Private Label (OEM/ODM) Activewear & Yoga Wear Manufacturing.

What Certifications Matter for Activewear Manufacturing?

Navigating the complex landscape of textile certifications can be overwhelming. Many businesses aren't aware of which certifications are truly relevant for activewear.

Key certifications for activewear include OEKO-TEX Standard 100 (ensuring textiles are free from harmful substances), ISO 9001 (quality management systems), social compliance audits like BSCI or WRAP (ethical manufacturing), and optional sustainability certifications like bluesign® (environmentally friendly production) or GRS (for recycled content).

At HAVING, we maintain multiple certifications to ensure our activewear meets international standards for safety, quality, and ethical manufacturing. Here's what you should know about relevant certifications:

Product Safety Certifications

OEKO-TEX Standard 100

- What It Certifies: Textiles tested for harmful substances

- Importance: Critical for products with prolonged skin contact

- Testing Scope: Tests for regulated and non-regulated substances

- Validity: Requires annual renewal and regular testing

UV Protection Certification (for outdoor activewear)

- What It Certifies: Fabric's ability to block harmful UV rays

- Importance: Relevant for outdoor performance wear

- Testing Method: UPF (Ultraviolet Protection Factor) rating

- Common Standard: AS/NZS 4399 or AATCC 183

Quality Management Certifications

ISO 9001

- What It Certifies: Quality management systems

- Importance: Demonstrates systematic approach to quality

- Requirements: Documented procedures, internal audits, continuous improvement

- Benefit: Reduces risk of quality inconsistencies

Social Compliance Certifications

Business Social Compliance Initiative (BSCI)

- What It Certifies: Ethical labor practices and working conditions

- Importance: Verifies ethical manufacturing

- Audit Areas: Fair wages, working hours, health and safety, no child labor

- Process: Independent third-party audits

Worldwide Responsible Accredited Production (WRAP)

- What It Certifies: Lawful, humane, and ethical manufacturing

- Importance: Internationally recognized social compliance program

- Focus Areas: Labor practices, workplace conditions, environmental responsibility

- Levels: Different certification levels based on compliance

Sustainability Certifications (Optional)

bluesign®

- What It Certifies: Environmentally friendly textile production

- Importance: Comprehensive approach to sustainable manufacturing

- Focus: Chemical safety, resource efficiency, consumer safety

- Benefit: Appeals to environmentally conscious brands

Global Recycled Standard (GRS)

- What It Certifies: Recycled content in products

- Importance: Relevant for activewear using recycled polyester

- Requirements: Minimum recycled content, chain of custody verification

- Benefit: Supports sustainability claims

Certification Verification

When evaluating manufacturer certifications:

- Request current certificates (not expired)

- Verify certification through the issuing body's website

- Check the scope of certification (specific to relevant products)

- Ask about certification maintenance procedures

For market insights and consumer preferences regarding certified products, visit our analysis of Understanding the Activewear & Yoga Wear Market: Trends, Demographics & Opportunities for B2B Buyers.

How Do You Ensure Consistent Quality at Scale?

Maintaining quality consistency while scaling production is a common challenge. Many manufacturers struggle to deliver the same quality level when moving from small orders to large production runs.

Ensuring consistent quality at scale requires standardized processes (documented procedures for all production steps), comprehensive training (ensuring all workers understand quality standards), statistical quality control (using data to identify and address variations), and continuous improvement systems (regularly reviewing and enhancing processes based on findings).

At HAVING, we've successfully scaled our activewear production to over $30 million in annual sales while maintaining consistent quality. Here are our key strategies for quality consistency at scale:

Standardization and Documentation

The foundation of consistent quality is standardized processes:

- Detailed Work Instructions: Step-by-step procedures for each operation

- Visual Standards: Physical examples of acceptable and unacceptable quality

- Measurement Specifications: Precise tolerances for all dimensions

- Construction Standards: Specific requirements for seams, stitches, and techniques

Training and Skill Development

Worker skill significantly impacts quality consistency:

- Comprehensive Initial Training: Thorough onboarding for new workers

- Skill Certification: Verification of competency before independent work

- Ongoing Skill Development: Regular training updates and improvements

- Cross-Training: Developing versatility to maintain flexibility

Statistical Process Control

Data-driven quality management enables consistency at scale:

- In-Process Measurements: Regular checking of key dimensions

- Defect Tracking: Monitoring types and frequencies of quality issues

- Root Cause Analysis: Identifying underlying causes of recurring problems

- Corrective Action Implementation: Systematic approach to resolving issues

Technology and Automation

Strategic use of technology enhances consistency:

- Automated Cutting: Ensuring precise pattern cutting

- Computer-Controlled Stitching: Maintaining consistent seam quality

- Digital Quality Inspection: Using technology to detect defects

- RFID Tracking: Monitoring products throughout production

For information on navigating supply chain and logistics considerations, visit our guide on From Factory to Warehouse: Understanding MOQs, Lead Times & Logistics in Activewear & Yoga Wear Sourcing.

Conclusion

Implementing robust quality control and adhering to manufacturing standards are essential for successful activewear sourcing. By understanding the unique testing requirements, establishing comprehensive QC processes, and partnering with properly certified manufacturers, businesses can ensure their products deliver consistent performance and build consumer trust.

At HAVING, our commitment to quality control has enabled us to scale activewear production while maintaining excellence, helping our partners build successful brands in this competitive category.

For a comprehensive overview of the entire activewear category, including market trends and business opportunities, visit our Ultimate B2B Guide to Sourcing & Selling Activewear & Yoga Wear.

Frequently Asked Questions (FAQ)

What is the most common quality issue in activewear manufacturing?

The most common quality issues are pilling (surface fuzzing that affects appearance), seam failure during stretch (particularly in high-stress areas), and opacity problems in leggings (becoming see-through when stretched). All can be prevented through proper material selection and construction techniques.

How often should activewear be tested during production?

Quality checks should occur at multiple stages: pre-production approval, first piece inspection, inline checks at regular intervals (typically every 1-2 hours), and final AQL inspection before shipping. Performance testing should be conducted on samples from each production lot.

What's the difference between first-party and third-party testing?

First-party testing is conducted by the manufacturer, while third-party testing is performed by independent laboratories. Third-party testing provides greater objectivity and is often required for certification or compliance verification.

How can I verify a manufacturer's quality claims?

Request test reports, visit facilities to observe testing procedures, ask for client references, and order samples for independent testing. Consider starting with a small production run to verify quality before larger commitments.

What's the minimum acceptable recovery rate for activewear fabrics?

Quality activewear should maintain at least 85% recovery after being stretched to 150% of original dimensions. Premium products often achieve 90-95% recovery, ensuring they maintain shape through multiple wearings and washings.

How do I establish quality standards for my activewear line?

Define clear specifications for performance attributes (stretch, recovery, moisture management), appearance standards (acceptable variations in color, construction), and durability requirements (wash cycles, abrasion resistance). Document these in a comprehensive tech pack and establish testing protocols to verify compliance.