Decoding Lingerie Trims: How Elastic Bands, Straps, Closures & Underwires Impact Cost & Wearer Experience?

The difference between ordinary lingerie and exceptional intimate wear often lies in the details most customers never see. Behind every comfortable bra strap and supportive underwire is a world of design decisions that significantly impact both manufacturing costs and wearer satisfaction.

The quality of trims used in lingerie production directly affects comfort, support, durability, and price point. Manufacturers who understand these components can create products that deliver superior value while maintaining reasonable production costs.

As a lingerie manufacturer with over two decades of experience serving 3,000+ stores across China, I've witnessed firsthand how seemingly minor trim choices can make or break a product line. Let me take you behind the scenes to understand the true impact of these essential components.

What Makes Elastic Bands So Critical to Lingerie Comfort?

The elastic band is the unsung hero of lingerie comfort. When customers complain about underwear that digs in, rolls, or loses shape after washing, they're experiencing the consequences of poor elastic quality.

High-quality elastic bands maintain their recovery properties even after repeated stretching and washing, providing consistent support without causing discomfort or irritation to the wearer.

Different types of elastic bands serve different purposes in lingerie:

| Elastic Type | Best Used For | Cost Impact | Wearer Experience |

|---|---|---|---|

| Plush-back elastic | Bra bands, waistbands | Medium-high | Superior comfort, reduced irritation |

| Picot edge elastic | Leg openings, decorative edges | Medium | Decorative finish, gentle on skin |

| Fold-over elastic | Edges requiring clean finish | Low-medium | Clean appearance, moderate comfort |

| Silicone-lined elastic | Strapless styles, stay-put features | High | Excellent grip, prevents slipping |

I once worked with a brand that switched from standard to plush-back elastic for their bestselling everyday bra. While material costs increased by 18%, customer satisfaction scores rose by 27%, and return rates dropped significantly. The investment in better elastic actually improved their profit margins through increased customer loyalty and reduced returns.

How Do Straps Affect Support and Comfort?

Straps are more than just a way to keep lingerie in place—they're engineering components that distribute weight and provide crucial support. The width, elasticity, and attachment methods all contribute to the wearer's comfort and the garment's functionality.

Premium lingerie straps typically use a combination of elastic and non-stretch materials to provide the perfect balance of flexibility and support, while budget options often rely on simple elastic that stretches out quickly.

When examining strap quality, consider these factors:

- Width: Wider straps distribute weight better and are less likely to dig into shoulders

- Adjustability range: Quality straps offer greater adjustment range to fit more body types

- Attachment method: Reinforced stitching at stress points prevents strap failure

- Material composition: Higher spandex content (around 15-20%) provides better recovery

In our factory, we've found that upgrading from basic 3/8" elastic straps to engineered straps with stabilized edges and controlled stretch increases production costs by approximately $0.40-0.60 per garment. However, this investment dramatically reduces customer complaints about straps that slip, twist, or dig in—issues that often lead to returns and lost customers.

Why Are Closures Worth the Investment?

Closures may seem like simple hardware, but they significantly impact both the user experience and the garment's lifespan. From hooks and eyes to front clasps and adjusters, these components face constant stress during wear.

The difference between premium and budget closures isn't just about appearance—it's about functionality, durability, and comfort against the skin.

| Closure Type | Quality Indicators | Cost Difference | Durability Impact |

|---|---|---|---|

| Hook & Eye | Nickel-free metal, reinforced stitching | +$0.15-0.30 per set | 2-3x longer before deformation |

| Front Clasps | Precision molding, smooth operation | +$0.40-0.75 per unit | Reduced breakage risk by 80% |

| Strap Adjusters | Metal vs. plastic, grip strength | +$0.10-0.25 per pair | Maintains adjustment 5x longer |

One of our clients initially balked at upgrading their hook-and-eye closures, as it would increase their production cost by about 2%. However, after implementing the change, warranty claims for closure failures dropped by 78%, and customer reviews specifically mentioned the improved quality of the hardware.

The Underwire Dilemma: Comfort vs. Support

Perhaps no lingerie component is more controversial than the underwire. Customers often have a love-hate relationship with underwires—appreciating the support while sometimes suffering from discomfort.

The quality of an underwire isn't determined by its presence or absence, but by its design, materials, and proper integration into the garment.

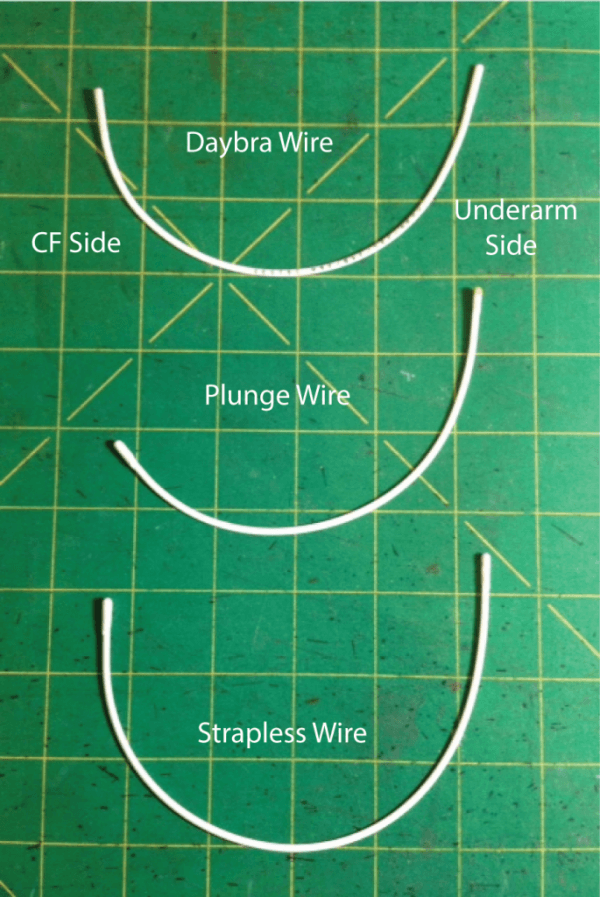

Key factors that determine underwire quality include:

- Material: Steel vs. plastic vs. newer composite materials

- Gauge: Thinner wires can be more comfortable but less supportive

- Coating: Quality underwires have smooth, durable coatings to prevent poking through

- Casing: The channel that houses the wire must be properly constructed

- Shape: Wires should be anatomically appropriate for the target customer

In our experience, investing an additional $0.30-0.50 per garment in premium underwires and proper casing construction reduces customer complaints about underwire discomfort by up to 65%. This is one area where cutting costs almost always leads to customer dissatisfaction.

How to Identify Quality Trims When Sourcing

When evaluating samples or discussing specifications with suppliers, here are key indicators of quality trims:

- Recovery test: Stretch elastic components and observe how quickly and completely they return to original shape

- Wash test: Quality trims maintain properties after multiple wash cycles

- Stress test: Apply tension to closures and attachment points to assess durability

- Comfort assessment: Evaluate edges, seams, and hardware for potential irritation points

- Certification: Request documentation for materials compliance and safety standards

I remember working with a new brand that was comparing two seemingly identical samples from different suppliers. The visible difference was minimal, but when we conducted recovery testing on the elastics, one sample maintained 95% recovery after 50 stretch cycles, while the other dropped to 68%. This simple test revealed a significant quality difference that would have affected the garment's lifespan.

Cost-Benefit Analysis: When to Invest in Premium Trims

Not every product requires top-tier components. The key is aligning trim quality with your brand positioning and customer expectations:

| Market Segment | Recommended Trim Quality | Cost Impact | Business Benefit |

|---|---|---|---|

| Budget/Mass Market | Standard with strategic upgrades | +3-5% production cost | Reduced returns, repeat purchases |

| Mid-range | Premium functional components | +8-12% production cost | Brand loyalty, positive reviews |

| Luxury | Top-tier throughout | +15-25% production cost | Premium positioning, higher margins |

Even for budget brands, strategic upgrades in high-impact areas can significantly improve customer satisfaction. For example, investing in better elastic for waistbands while maintaining standard closures can address the most common comfort complaints without dramatically increasing costs.

Communicating Trim Requirements to Suppliers

Clear communication with suppliers is essential for getting the trim quality you need. Here's how to effectively specify your requirements:

- Provide reference samples of acceptable quality standards

- Create a detailed trim specification sheet with exact measurements and materials

- Request material certifications for compliance and safety standards

- Establish testing protocols for evaluating samples

- Develop a quality control checklist specifically for trim components

When we work with new clients, we create a comprehensive trim library with approved components that meet their quality standards. This eliminates confusion and ensures consistency across production runs.

Conclusion

The hidden components of lingerie—elastic bands, straps, closures, and underwires—play a crucial role in determining both production costs and customer satisfaction. By understanding the impact of these elements, brands can make informed decisions about where to invest for maximum return.

Remember that in intimate apparel, the details customers can't see often determine whether they'll return for another purchase. Strategic investment in quality trims can transform an ordinary product into one that delivers exceptional comfort, support, and durability—creating loyal customers and strengthening your brand reputation.