Ihre Marke, Ihr Produkt: Der komplette Leitfaden für die Aktivbekleidung für Private Label (OEM/ODM) & Yoga Wear Manufacturing?

Viele Unternehmen zögern, aufgrund der wahrgenommenen Komplexität ihre eigene Aktivkleidung für Marken zu entwickeln. Sie vermissen die höheren Margen und Markentreue, die mit Handelsmarkenangeboten ausgestattet sind und sich stattdessen für die Weiterverkauf bestehender Marken mit niedrigeren Gewinnmargen niederlassen.

Private Label Activewear ermöglicht es Unternehmen, Branding, Preisgestaltung und Produktspezifikationen zu kontrollieren und gleichzeitig höhere Gewinnmargen zu erzielen (typischerweise 50-70% gegenüber 30-40% für den Weiterverkauf). OEM/ODM -Fertigungspartner behandeln die technischen Aspekte, während Sie sich auf Marketing und Vertrieb konzentrieren und ein einzigartiges Angebot schaffen, das Kundenbindung aufbaut.

At HAVING, we've guided numerous brands through the process of developing their own private label activewear lines. Our journey to $30 million in annual sales serving over 3,000 stores has given us deep insights into successful private label development. Let me share what we've learned about creating your own branded activewear products.

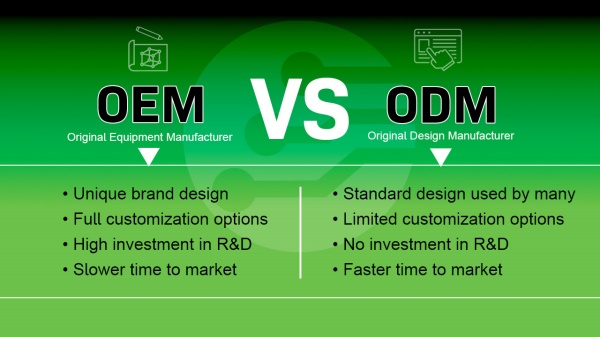

What's the Difference Between OEM and ODM Manufacturing?

Understanding these two manufacturing approaches is the first step in developing your private label strategy. Many businesses aren't clear on which option best suits their needs and capabilities.

OEM (Original Equipment Manufacturing) involves providing detailed specifications to a manufacturer who produces according to your requirements—ideal for brands with clear design vision and technical knowledge. ODM (Original Design Manufacturing) utilizes the manufacturer's existing designs with your branding applied—perfect for faster market entry with reduced development costs.

At HAVING, we offer both manufacturing approaches to accommodate different business needs and capabilities. Here's a detailed comparison to help you determine which approach is right for your brand:

OEM -Herstellung (Originalausrüstung Herstellung)

Definition: Sie geben detaillierte Spezifikationen und Designs an. Wir fertigen nach Ihren Anforderungen.

Vorteile:

- Vollständige Kontrolle über Produktspezifikationen

- Einzigartige Produkte exklusiv für Ihre Marke

- Differenzierung von Wettbewerbern

- Fähigkeit, bestimmte Innovationen umzusetzen

Überlegungen:

- Erfordert mehr technisches Wissen

- Längere Entwicklungszeitleiste

- Höhere Entwicklungskosten

- Typischerweise höhere Mindestbestellmengen (MOQs)

Beste für:

- Etablierte Marken mit klarer Vision

- Unternehmen mit technischem Fachwissen

- Marken, die eine signifikante Differenzierung suchen

- Unternehmen mit früheren Bekleidungserfahrungen

ODM -Fertigung (Originaldesignherstellung)

Definition: Wir bieten vorhandene Designs, die Sie an Ihr Branding anpassen können.

Vorteile:

- Schneller Zeit zum Markt

- Niedrigere Entwicklungskosten

- Bewährte Designs mit getesteter Leistung

- Niedrigere Mindestbestellmengen

- Reduzierte technische Anforderungen

Überlegungen:

- Weniger Produkteinheitlichkeit

- Eingeschränkte Differenzierung von Wettbewerbern

- Weniger Kontrolle über technische Spezifikationen

Beste für:

- Neue Marktteilnehmer

- Marken testen die Kategorie Activeweare

- Unternehmen mit begrenzten technischen Ressourcen

- Unternehmen, die schnellere Startzeitpläne suchen

Hybridansatz

Viele unserer erfolgreichsten Partner verwenden einen hybriden Ansatz:

- Beginnen Sie mit ODM für den ersten Markteintritt

- Sammeln Sie Kundenfeedback- und Verkaufsdaten

- Übergang nach und nach zu OEM, um einzigartige Funktionen zu erhalten

- Entwickeln Sie proprietäre Elemente und halten Sie bewährte Komponenten beibehalten

Diese Strategie minimiert das Risiko und ermöglicht die Erhöhung der Differenzierung im Laufe der Zeit.

Ausführliche Informationen zu Aktivkleidungstechnologie und Materialien, die Entscheidungen zur Produktentwicklung beeinflussen, besuchen Sie unseren umfassenden Leitfaden: Aktivkleidung & Yoga Wear -Technologie & Materials: A Buyer's Guide to Performance Fabrics, Construction & Haltbarkeit.

What's the Process for Developing Private Label Activewear?

Der Entwicklungsprozess kann ohne klare Roadmap entmutigend erscheinen. Viele Unternehmen unterschätzen die erforderlichen Zeit und Schritte, was zu überstürzten Entscheidungen und suboptimalen Produkten führt.

Der Handelsmarkenentwicklungsprozess dauert in der Regel 3-6 Monate und umfasst: Erstberatung und Konzeptentwicklung (1-2 Wochen), Materialauswahl und technische Spezifikation (2-3 Wochen), Stichproben und Revisionen (4-6 Wochen), Produktionsvorbereitung (2-3 Wochen) und Fertigung (4-6 Wochen). Jede Phase erfordert eine klare Kommunikation und Entscheidungsfindung, um sicherzustellen, dass das Endprodukt den Erwartungen entspricht.

At HAVING, we've streamlined our development process based on experience with numerous private label partners. Here's our step-by-step approach:

Phase 1: Beratung & Konzeptentwicklung (1-2 Wochen)

Schlüsselaktivitäten:

- Erste Beratung zum Verständnis der Markenvision

- Zielmarkt- und Positionierungsdiskussion

- Vorläufiger Stil und Funktionsplanung

- Budget- und Zeitleisteneinrichtung

- Wettbewerbsanalyse und Marktpositionierung

Ergebnisse:

- Projektbrief

- Vorläufige Produktspezifikationen

- Entwicklungszeitleiste

- Erste Preisschätzungen

Phase 2: Materialauswahl & Technische Spezifikation (2-3 Wochen)

Schlüsselaktivitäten:

- Stoffauswahl basierend auf Leistungsanforderungen

- Auswahl an Farb- und Trimmauswahl

- Bestimmung der Konstruktionsmethode

- Technische Spezifikationsentwicklung

- Preisfindung

Ergebnisse:

- Materialmuster

- Technische Spezifikationsblätter

- Komponentenliste

- Überarbeitete Preisschätzungen

Phase 3: Probenahme & Überarbeitungen (4-6 Wochen)

Schlüsselaktivitäten:

- Entwicklung von anfänglichen Prototypen

- Anpassungsbewertung

- Leistungstests

- Entwurfsverfeinerungen

- Endgültige Stichprobengenehmigung

Ergebnisse:

- Erste Prototypen

- Testberichte

- Überarbeitete Proben

- Endgültige zugelassene Proben

- Produktionsbereitete Spezifikationen

Phase 4: Produktionsvorbereitung (2-3 Wochen)

Schlüsselaktivitäten:

- Materialbeschaffung

- Produktionsplanung

- Qualität des Qualitätskontrollprotokolls

- Verpackungsentwicklung

- Genehmigung vor der Produktion

Ergebnisse:

- Produktionsplan

- Qualitätskontrollstandards

- Verpackungsmuster

- Vorproduktionsproben

Phase 5: Herstellung (4-6 Wochen)

Schlüsselaktivitäten:

- Massenproduktion

- Inline-Qualitätskontrolle

- Endinspektion

- Verpackung und Etikettierung

- Versandvorbereitung

Ergebnisse:

- Fertige Produkte

- Qualitätskontrollberichte

- Versanddokumentation

Informationen zum Aufbau einer kompletten Produktlinie für Aktivkleidung finden Sie in unserem Leitfaden auf Kuratieren Sie Ihre Kollektion: Ein B2B -Leitfaden für Activewear & Yoga -Verschleißstile, Funktionen & Materialoptionen.

Welche Anpassungsoptionen stehen für Private Label Activewear zur Verfügung?

Understanding customization possibilities helps businesses create truly distinctive products. Many aren't aware of the full range of options available beyond basic branding.

Zu den Optionen für Aktivkleidung gehören die Auswahl der Stoffauswahl (Leistungsstufe, Komposition, Gewicht), Farbentwicklung, Druckdesign, Konstruktionstechniken, Brandingelemente (Logos, Etiketten, Wärmeübertragungen), Verpackungsdesign und Funktionsfunktionen (Taschen, Mesh -Panels, Spezialnaht). Der Anpassungsgrad korreliert typischerweise mit minimalen Bestellmengen und Entwicklungszeitplänen.

At HAVING, we offer extensive customization options for our private label partners. Here's an overview of the key areas where you can differentiate your products:

Materialanpassung

Stoffoptionen

- Leistungsniveaus: Basic, moderat oder fortschrittliches Feuchtigkeitsmanagement

- Zusammensetzung: Polyester/Elastan, Nylon/Elastan, nachhaltige Mischungen

- Gewicht: Leicht für hohe Intensität, Mittelgewicht für Studio, Schwergewicht für die Komprimierung

- Handgefühl: Seidig, wottony, gebürstet, komprimiert

- Besondere Eigenschaften: UV-Schutz, Anti-Odor, Schnelltrocknen, zusätzliche Strecke

Farb- und Druckoptionen

- Feste Farben: Benutzerdefinierte Farbanpassung an Ihre Spezifikationen

- Härteeffekte: Marled oder räumlich gefärbte Erscheinungen

- All-Over-Drucke: Benutzerdefinierte Muster, Digitaldruck

- Platzierungsdrucke: Strategiedesign -Platzierung

- Spezialisation: Matte, Glanz oder strukturierte Effekte

Entwurfsanpassung

Stiloptionen

- Silhouette -Modifikationen: Einstellungshöhe, Beinform, Riemendesign einstellen

- Baudetails: Nahtplatzierung, Paneldesign, Zwickelform

- Funktionselemente: Taschenzugabe oder -änderung, Platzierung der Netzwerkplatte

- Leistungsfunktionen: Kompressionszonen, Lüftungsplatzierung

Brandingelemente

- Logo -Anwendung: Drucken, Stickerei, Wärmeübertragung, Silikon

- Etikettendesign: Hauptbezeichnungen, Pflegeetiketten, Größenetiketten

- Hardware: Reißverschluss zieht, Kabelende, Schnappschüsse mit Logo

- Elastische Behandlungen: Markenbänder, benutzerdefinierte elastische Farben

Verpackungsanpassung

- Hang -Tags: Benutzerdefiniertes Design, Form, Material

- Produktverpackung: Polybeutel, Kisten, nachhaltige Alternativen

- Kollateralmaterial: Einfügungen, Pflegeanweisungen, Markengeschichtenerzählen

- Bündelungsoptionen: Sets, Multi-Packs, Geschenkverpackungen

Anpassungsstufen

Wir bieten normalerweise drei Anpassungsebenen an:

| Anpassungsstufe | What's Included | Typischer MOQ |

|---|---|---|

| Grundes Branding | Standarddesigns mit Ihren Etiketten, Logos, Verpackung | 500 Einheiten |

| Mäßige Anpassung | Farbwechsel, Materialauswahl, grundlegende Designänderungen | 1.000-3.000 Einheiten |

| Vollständige Anpassung | Einzigartige Designs, benutzerdefinierte Materialien, spezielle Funktionen | 3.000+ Einheiten |

Informationen zu Qualitätskontrollstandards für Private -Label -Produkte finden Sie in unserer Ressource auf Gewährleistung von Produktexzellenz: Qualitätskontrolle & Fertigungsstandards für Activewear & Yoga tragen Beschaffung.

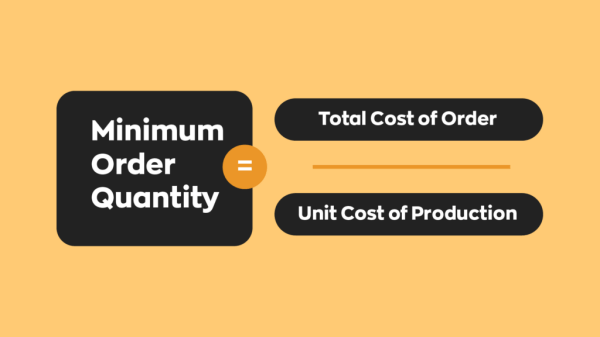

Was sind die minimalen Bestellmengen und Kostenüberlegungen?

Understanding MOQs and cost factors is crucial for financial planning. Many businesses are surprised by minimum order requirements or don't fully understand the factors that influence pricing.

Mindestbestellmengen für Private-Label-Aktivkleidung reichen von 500-3.000 Einheiten pro Stil/Farbe, abhängig vom Anpassungsniveau. Zu den wichtigsten Kostenfaktoren gehören die Auswahl der Stoffe (technische Merkmale erhöhen Kosten), Komplexität des Bauwerks (mehr Panels und spezielle Nahtsteigerungskosten), Anpassungsabschluss, Auftragsvolumen (größere Bestellungen reduzieren die Kosten) und die Komplexität der Verpackung.

At HAVING, we've structured our private label program to accommodate various business sizes while maintaining quality standards. Here's what you need to know about MOQs and pricing:

Mindestbestellmengen

Unsere MOQ -Struktur ist so konzipiert, dass sie zugänglich ist und gleichzeitig die Produktionseffizienz sicherstellt:

Nach Geschäftsgröße

- Kleine Marken/Startups: 500 Einheiten pro Stil

- Mittelmarken: 1.000-3.000 Einheiten pro Stil

- Große Einzelhändler: 3.000+ Einheiten pro Stil

Durch Anpassungsstufe

- Standarddesigns mit Branding: 500 Einheiten pro Stil/Farbe

- Modifizierte Standarddesigns: 1.000 Einheiten pro Stil/Farbe

- Voll benutzerdefinierte Designs: 2.000-3.000 Einheiten pro Stil/Farbe

Nach Materialtyp

- Stützmaterialien: Niedrigere MOQs (500-1.000)

- Benutzerdefinierte Standardmaterialien: Medium MOQs (1.000-2.000)

- Benutzerdefinierte Materialien: Höhere MOQs (3.000+)

Kostenfaktoren

Mehrere Elemente beeinflussen die endgültigen Kosten für Handelsmarken -Aktivkleidung:

Materialauswahl

| Materialtyp | Relative Kostenauswirkungen |

|---|---|

| Basic Polyester/Elastane | Grundlinie |

| Premium Nylon/Elastane | +15-25% |

| Recycelte Materialien | +10-20% |

| Technische Leistungsstoffe | +20-40% |

Baukomplexität

- Grundkonstruktion: Minimale Panels, Standardnähte (Basiskosten)

- Mäßige Komplexität: Mehrere Panels, einige spezielle Nähte (+10-20%)

- Hohe Komplexität: Zahlreiche Panels, umfangreiche Spezialausnähte (+20-30%)

- Technische Konstruktion: Verbundene Nähte, komplexe Verkleidung, Spezialmerkmale (+30-50%)

Bestellvolumen

Volumenrabatte folgen normalerweise diesem Muster:

- 500-1.000 Einheiten: Grundpreis

- 1.001-3.000 Einheiten: 5-10% Rabatt

- 3.001-5.000 Einheiten: 10-15% Rabatt

- 5.001-10.000 Einheiten: 15-20% Rabatt

- Mehr als 10.000 Einheiten: 20%+ Rabatt (verhandelbar)

Verpackungsoptionen

- Grundlegende Polybeutel: Minimale Kosten

- Benutzerdefinierte gedruckte Polybeutel: Niedrige zusätzliche Kosten

- Hängen Sie Tags und Einfügungen auf: Niedrige bis mittlere zusätzliche Kosten

- Benutzerdefinierte Boxen: Medium bis hohe zusätzliche Kosten

Beispiele für Preisspanne

Während spezifische Preise von vielen Faktoren abhängen, finden Sie hier typische Großhandelspreisbereiche:

- Basis -Handelsmarktlabel: $ 8-12 pro Einheit

- Mittelklasse-Handelsmarktlabel: $ 12-18 pro Einheit

- Premium -Handelsmarktlabel: $ 18-25+ pro Einheit

Unter Erkenntnisse über die Preisstrategie und die Gewinnmargen untersuchen Sie unsere detaillierte Analyse: Maximieren Sie Ihren ROI: Activewear & Yoga tragen Großhandelspreise, Einzelhandelsmargen & Rentabilitätsanalyse.

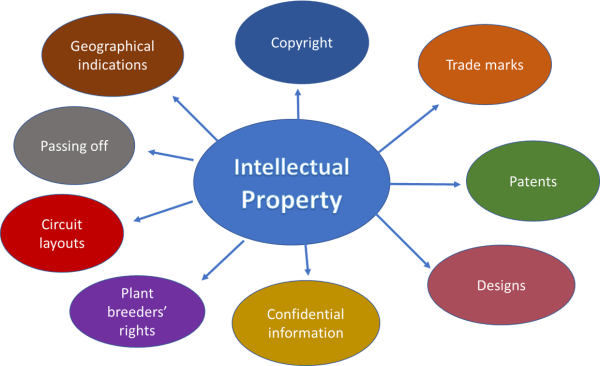

Wie schützen Sie Ihre Marke und Ihr geistiges Eigentum?

Bei der Entwicklung von Private -Label -Produkten treten häufig geistige Eigentumsprodukte auf. Viele Unternehmen sorgen sich über Designschutz und Exklusivität, wenn sie mit Herstellern in Übersee zusammenarbeiten.

Der Schutz Ihrer Marke und des geistigen Eigentums beinhaltet mehrere Strategien: Klare Vertraulichkeitsvereinbarungen, eingeschränkte Verbreitung technischer Spezifikationen, Markenregistrierung in wichtigen Märkten, Designpatente für wirklich innovative Merkmale und die Zusammenarbeit mit renommierten Herstellern mit etablierten IP -Schutzprotokollen.

At HAVING, we respect our partners' intellectual property and have established protocols to protect their designs and innovations. Here are key strategies we recommend:

Rechtsschutzmaßnahmen

Vertraulichkeitsvereinbarungen

- Geheimhaltungsvereinbarungen (NDAs): Sign before sharing designs or concepts

- Vertraulichkeitsklauseln: In alle Produktionsvereinbarungen einbeziehen

- Informationsklassifizierung: Markieren Sie klar vertrauliche Dokumente

Registrierung von geistigem Eigentum

- Markenregistrierung: Registrieren Sie Ihren Markennamen und Ihr Logo in den Fertigungsländern

- Designpatente: Betrachten Sie für wirklich einzigartige funktionale oder ästhetische Elemente

- Versorgungspatente: Für innovative technische Lösungen (selten in Activewear)

Vertragliche Schutz

- Exklusivitätsklauseln: Verhindern Sie die Herstellung identischer Produkte für Wettbewerber

- Eigentümerklauseln: Geben Sie eindeutig das Eigentum an Entwürfen und Spezifikationen fest

- Wettbewerbsvorkehrungen: Verhindern Sie den Hersteller daran, Ihren Markt direkt einzutreten

Praktische Schutzstrategien

Informationsmanagement

- Notwendigkeitsbasis: Begrenzen Sie den vollständigen Entwurfszugriff auf essentielles Personal

- Fachabteilung: Teilen Sie das Produktionswissen zwischen verschiedenen Teams

- Digitale Sicherheit: Verwenden Sie sichere Methoden zur Freigabe und Kommunikation von Dateien

Fertigungsbeziehung

- Reputationsforschung: Arbeiten Sie mit Herstellern mit etabliertem Ruf zusammen

- Referenzprüfungen: Sprechen Sie mit aktuellen Kunden über IP -Schutzerfahrungen

- Laufende Überwachung: Reguläre Marktprüfungen für nicht autorisierte Kopien

Produktionsschutz

- Produktionszählung: Strenge Abrechnung aller Materialien und Fertigwaren

- Qualitätsmarksysteme: Versteckte Kennungen in authentischen Produkten

- Zerstörung von Sekunden: Ordnungsgemäße Entsorgung abgelehnter Produkte

Informationen zum Navigieren von Lieferketten- und Logistiküberlegungen finden Sie in unserem Leitfaden zu Von der Fabrik zum Lager: MOQS verstehen, Vorlaufzeiten & Logistik in Activewear & Yoga tragen Beschaffung.

Was sind die Vorteile der Partnerschaft für Private Label Activewear?

Der richtige Fertigungspartner zu finden, ist entscheidend für den Erfolg von Private Label. In vielen Lieferanten fehlt das spezialisierte Fachwissen für technische Activewear -Produkte.

Der ideale Partner für Activewear Manufacturing kombiniert technisches Know -how in Leistungsstoffe, nachgewiesene Qualitätskontrollsysteme, Wettbewerbspreise und flexible MOQs. Suchen Sie nach Herstellern mit nachgewiesenem Erfolg bei der Skalierungsproduktion, einem Engagement für Qualität und einem kollaborativen Ansatz für die Produktentwicklung.

At HAVING, we've established ourselves as a leader in activewear manufacturing through our work with major retailers and brands. Our journey to $30 million in annual sales serving over 3,000 stores demonstrates our ability to scale while maintaining quality.

Unsere einzigartigen Vorteile

Was unterscheidet sich aufeinanderisten:

-

"Body-vor-Fabric" Philosophie: Unser Design -Ansatz priorisiert Komfort, Passform und Leistung, um sicherzustellen, dass sich die Kleidungsstücke mit dem Körper bewegen, anstatt ihn einzuschränken.

-

Niedrige MOQ -Flexibilität: Wir bieten branchenführende niedrige Mindestmindest von nur 500 Teilen pro Stil an, wodurch das Handelsmarkt für Unternehmen aller Größen zugänglich ist.

-

Technisches Know -how: Unsere spezialisierten Kenntnisse über Leistungsstoffe und Konstruktionstechniken gewährleisten Produkte, die wie versprochen abschneiden.

-

Umfassende Unterstützung: Wir führen Partner durch den gesamten Entwicklungsprozess, vom Konzept bis zur Lieferung.

-

Bewährte Skala: Mit einem Jahresumsatz von 30 Millionen US -Dollar und über 3.000 Geschäften haben wir unsere Fähigkeit gezeigt, eine konsistente Qualität bei Lautstärke zu liefern.

Unser Privatbezeichnungsprozess

Das Arbeiten mit Have ist unkompliziert:

- Beratung: Wir diskutieren Ihre Markenvision, Zielmarkt und Produktbedürfnisse

- Design & Entwicklung: Wir erstellen oder passen Designs an, um Ihre Spezifikationen zu erfüllen

- Probenahme: Wir produzieren Prototypen für Ihre Zustimmung

- Produktion: Wir stellen Ihre Produkte mit strenger Qualitätskontrolle her

- Lieferung: Wir verwalten die Logistik, um Produkte effizient in Ihr Lagerhaus zu bringen

Abschluss

Die Entwicklung Ihres eigenen Private Label Activewear bietet erhebliche Vorteile hinsichtlich der Markenkontrolle, des Margenpotentials und der Marktdifferenzierung. Durch das Verständnis des OEM/ODM -Prozesses, der Anpassungsoptionen, der Kostenüberlegungen und der Strategie zur Schutz von geistigem Eigentum können Unternehmen erfolgreich einzigartige Produkte schaffen, die Kundenbindung aufbauen und die Rentabilität fördern.

At HAVING, we're committed to supporting your private label journey with our manufacturing expertise and collaborative approach to product development.

Eine umfassende Übersicht über die gesamte Kategorie Activewear, einschließlich Markttrends und Geschäftsmöglichkeiten, besuchen Sie unsere Ultimativer B2B -Leitfaden zur Beschaffung & Verkaufen activewear & Yoga -Verschleiß.

Häufig gestellte Fragen (FAQ)

What's the difference between private label and white label activewear?

Private Label beinhaltet in der Regel mehr Anpassungen und einzigartige Spezifikationen, die auf Ihre Marke zugeschnitten sind, während White Label auf Standardprodukte bezieht, die von einem Lieferanten hergestellt werden, zu dem Sie einfach Ihr Branding mit minimalen Änderungen hinzufügen.

Wie lange dauert es, um eine Handelsmarken -Activewear -Linie zu entwickeln?

Der vollständige Prozess dauert in der Regel 3-6 Monate vom ersten Konzept bis zum fertigen Produkt, wobei Zeitlinienschwankungen auf der Anpassungsstufe, der Materialauswahl und der Bestellkomplexität basieren.

What's the minimum investment needed to start a private label activewear line?

Erwarten Sie für eine grundlegende Sammlung (2-3 Stile in 2 Farben) eine Mindestinvestition von 8.000 bis 15.000 USD, abhängig von der Anpassungsniveau, der Materialauswahl und der Bestellmengen.

Kann ich kleine Änderungen an vorhandenen Designs vornehmen, ohne den vollständigen MOQS zu erfüllen?

Ja, viele Hersteller bieten modifizierte Standarddesigns mit niedrigeren MOQs an als vollständig benutzerdefinierte Produkte. Dieser "Hybridansatz" Ermöglicht eine gewisse Differenzierung ohne die höheren Mindestmindest für vollständig benutzerdefinierte Designs.

Wie sorge ich Qualitätskontrolle für meine Private -Label -Produkte?

Arbeiten Sie mit Herstellern zusammen, die Qualitätskontrollprozesse festgelegt haben, fordern Sie detaillierte Testberichte an, berücksichtigen Inspektionen von Drittanbietern für große Bestellungen und beginnen mit kleineren Produktionsläufen, um die Qualität vor dem Skalieren zu überprüfen.

Welche Informationen müssen ich bereitstellen, um den Handelsbezeichnungsvorgang zu starten?

Seien Sie bereit, Ihren Zielmarkt, die gewünschten Preispunkte, Stilvorstellungen, Leistungsanforderungen, Brandingelemente, Verpackungsideen und Zeitleistenerwartungen zu teilen. Je spezifischer Ihre Vision ist, desto effizienter kann der Entwicklungsprozess fortgesetzt werden.

Holen Sie sich ein kostenloses Angebot für Ihre Activewear -Projekte