التنقل في المشهد المعقد للوائح النسيج ومعايير السلامة أمر شاق. تكتشف العديد من الشركات مشكلات الامتثال بعد فوات الأوان ، مما يؤدي إلى استدعاءات المنتجات المكلفة أو مشاكل الاستيراد أو حتى المسؤولية القانونية التي تضر بسمعة العلامة التجارية.

يجب أن تلبي الملابس الداخلية الفترة المعايير المختلفة للسلامة والجودة ، بما في ذلك شهادة Oeko-Tex القياسية 100 (ضمان أن تكون المنسوجات خالية من المواد الضارة) ، وبروتوكولات اختبار الامتصاص ، واللوائح الخاصة بالمنطقة مثل الوصول إلى الاتحاد الأوروبي أو CPSIA US. إن التحقق الخالي من PFAS مهم بشكل متزايد حيث يدرك المستهلكون المخاوف الصحية المحتملة.

في الحصول على الأولوية للامتثال والسلامة في جميع منتجات الملابس الداخلية الخاصة بنا. لقد علمنا تجربتنا في تصنيع أكثر من مليوني وحدة سنويًا لتجار التجزئة الرئيسيين مثل Primark الأهمية الحاسمة لتلبية المعايير العالمية. اسمحوا لي أن أشارك ما تعلمناه حول التنقل في عالم الامتثال والشهادات ومعايير المصنع.

ما هي الشهادات المهمة للملابس الداخلية الفترة؟

إن فهم الشهادات ذات الصلة حقًا يمكن أن يكون ساحقًا. تضيع العديد من الشركات الموارد على شهادات غير ضرورية بينما تفتقد تلك التي تعتبر حاسمة لأسواقها المستهدفة.

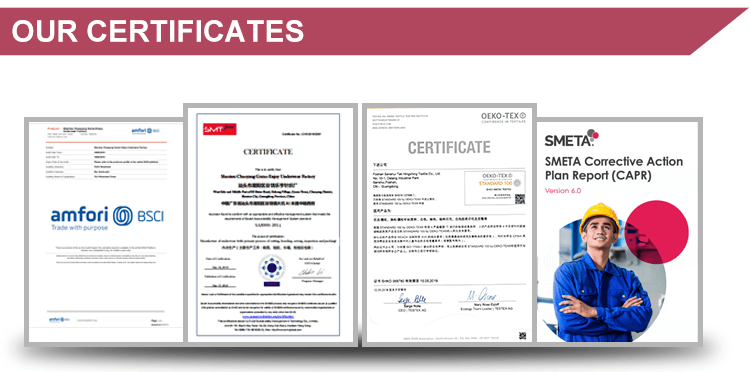

تشمل الشهادات الرئيسية للملابس الداخلية الفترة Oeko-Tex Standard 100 (ضمان أن تكون المنسوجات خالية من المواد الضارة) ، و ISO 9001 (أنظمة إدارة الجودة) ، ومراجعات الامتثال الاجتماعي مثل BSCI أو Wrap (التصنيع الأخلاقي) ، وشهادات الاستدامة الاختيارية مثل GOTS (للمواد العضوية) أو GRS (للمحتوى المعاد تدويره).

في امتلاكنا ، نحافظ على شهادات متعددة لضمان تلبية دورتنا الداخلية في الدورات المعايير الدولية للسلامة والجودة والتصنيع الأخلاقي. إليك ما تحتاج لمعرفته حول الشهادات ذات الصلة:

شهادات سلامة المنتج الأساسية

Oeko-Tex Standard 100

ما يشهد: تم اختبار المنسوجات للمواد الضارة

أهمية: حاسمة للمنتجات ذات التلامس الجلدي المطول

نطاق الاختبار: اختبارات المواد الخاضعة للتنظيم وغير المنظمة

صحة: يتطلب التجديد السنوي واختبار منتظم

يعد Oeko-Tex Standard 100 مهم بشكل خاص للملابس الداخلية الفترة بسبب الطبيعة الحميمة للمنتج والاتصال الموسع مع المناطق الحساسة في الجسم. تضمن الشهادة أن جميع المكونات - من الأقمشة إلى المواضيع ، واللاستيك ، والمطبوعات - تتطلب متطلبات السلامة الصارمة.

التحقق خالي من PFAS

ما تتحقق: منتجات خالية من مواد الفرد والبولي فلووروكيل

أهمية: Addressing growing consumer concern about "forever chemicals"

طريقة الاختبار: تحليل مختبر متخصص

ملحوظة: ليست شهادة رسمية ولكن وثائق اختبار ذات أهمية متزايدة

أبرزت الدعاوى القضائية الأخيرة واهتمام وسائل الإعلام المخاوف بشأن PFAs في الملابس الداخلية. على الرغم من أنها ليست شهادة رسمية ، إلا أن التحقق الخالي من PFAS من خلال الاختبارات المعملية أصبح ضروريًا لثقة المستهلك.

شهادات إدارة الجودة

ISO 9001

ما يشهد: أنظمة إدارة الجودة

أهمية: يوضح النهج المنهجي للجودة

متطلبات: الإجراءات الموثقة ، التدقيقات الداخلية ، التحسين المستمر

فائدة: يقلل من خطر التناقضات الجودة

تشير شهادة ISO 9001 إلى أن الشركة المصنعة قامت بتنفيذ عمليات إدارة الجودة المنهجية ، وهو أمر مهم بشكل خاص للمنتجات الوظيفية مثل الملابس الداخلية الفترة حيث يكون تناسق الأداء أمرًا بالغ الأهمية.

شهادات الامتثال الاجتماعي

مبادرة الامتثال الاجتماعي التجاري (BSCI)

ما يشهد: ممارسات العمل الأخلاقية وظروف العمل

أهمية: يتحقق من التصنيع الأخلاقي

مناطق التدقيق: الأجور العادلة ، ساعات العمل ، الصحة والسلامة ، لا عمل للأطفال

عملية: عمليات تدقيق مستقلة من الطرف الثالث

الإنتاج المعتمد العالمي المسؤول (WRAP)

ما يشهد: القانون القانوني والإنساني والأخلاقي

أهمية: برنامج الامتثال الاجتماعي المعترف به دوليا

مجالات التركيز: ممارسات العمل ، وظروف مكان العمل ، والمسؤولية البيئية

مستويات: مستويات شهادة مختلفة تستند إلى الامتثال

أصبحت شهادات الامتثال الاجتماعي ذات أهمية متزايدة حيث يطلب المستهلكون وتجار التجزئة شفافية حول ظروف التصنيع. يتطلب العديد من تجار التجزئة الرئيسيين الآن هذه الشهادات من مورديهم.

شهادات الاستدامة (اختيارية)

معيار المنسوجات العضوية العالمية (GOTS)

ما يشهد: الحالة العضوية للمنسوجات

أهمية: ذات صلة بالملابس الداخلية للقطن العضوي

متطلبات: الحد الأدنى 70 ٪ من الألياف العضوية ، والمواد الكيميائية المقيدة ، والإدارة البيئية

فائدة: نداء للمستهلكين الواعيين للبيئة

المعيار العالمي المعاد تدويره (GRS)

ما يشهد: المحتوى المعاد تدويره في المنتجات

أهمية: ذات صلة بالملابس الداخلية الفترة باستخدام المواد المعاد تدويرها

متطلبات: الحد الأدنى من المحتوى المعاد تدويره ، سلسلة التحقق من الحضانة

فائدة: يدعم مطالبات الاستدامة

على الرغم من أنه ليس ضروريًا لجميع الملابس الداخلية ، إلا أن شهادات الاستدامة يمكن أن توفر مزايا تسويقية كبيرة وتناشد المستهلكين الواعيين بيئيًا.

| شهادة | أساسي أو اختياري | نطاق التكلفة النموذجي | تردد التجديد |

|---|---|---|---|

| Oeko-Tex Standard 100 | ضروري | 1،000-3000 دولار | سنوي |

| اختبار PFAS | ضروري | 300-800 دولار لكل اختبار | لكل تشغيل الإنتاج |

| ISO 9001 | مُستَحسَن | 5،000-15000 دولار | 3 سنوات مع عمليات التدقيق السنوية |

| BSCI/التفاف | ضروري بشكل متزايد | 3،000-8000 دولار | سنوي أو كل سنتين |

| حصلت | اختياري (ضروري للمطالبات العضوية) | 5،000-20،000 دولار | سنوي |

للحصول على معلومات مفصلة عن تقنية الملابس الداخلية والمواد التي قد تتطلب شهادات محددة ، تفضل بزيارة دليلنا الشامل: الفترة تكنولوجيا الملابس الداخلية & المواد: دليل المشتري للامتصاص والأقمشة & تسرب التسرب.

ما هي اللوائح الإقليمية التي يجب أن تلتقي بها الملابس الداخلية؟

الأسواق المختلفة لها متطلبات تنظيمية مميزة. يمكن أن يؤدي الفشل في تلبية هذه المعايير إلى رفض المنتجات في الجمارك أو الاستدعاء القسري أو العقوبات القانونية.

يجب أن تتوافق الملابس الداخلية في الفترة للوائح الخاصة بالمنطقة بما في ذلك الوصول إلى الاتحاد الأوروبي (تقييد المواد الكيميائية الخطرة) ، و CPSIA الأمريكية (خاصة بالنسبة لمنتجات المراهقين) ، والاقتراح في كاليفورنيا 65 ، ومتطلبات وضع العلامات على النسيج الخاصة بالبلد. كل سوق لديه احتياجات امتثال فريدة يجب معالجتها قبل الاستيراد.

في الحصول على شركائنا ، نساعد شركائنا على التنقل في المشهد المعقد للوائح العالمية. إليك ما تحتاج لمعرفته حول المتطلبات الإقليمية الرئيسية:

لوائح أمريكا الشمالية

الولايات المتحدة

قانون تحسين سلامة المنتجات الاستهلاكية (CPSIA)

- قابلية التطبيق: ذات صلة بشكل خاص بالملابس الداخلية الفترة التي يتم تسويقها إلى المراهقين الذين تقل أعمارهم عن 14 عامًا

- متطلبات: اختبار الرصاص والفثالات والمواد المقيدة الأخرى

- توثيق: شهادة منتجات الأطفال (CPC) لمنتجات الشباب

متطلبات لجنة التجارة الفيدرالية (FTC)

- قانون تحديد منتجات ألياف النسيج: وضع علامة على محتوى الألياف الدقيقة

- قاعدة العلامات رعاية: تعليمات الرعاية الواضحة

- قدمت في مطالبات الولايات المتحدة الأمريكية: معايير صارمة لمطالبات بلد المنشأ

اقتراح كاليفورنيا 65

- متطلبات: ملصقات تحذير للمنتجات التي تحتوي على مواد كيميائية مدرجة

- الأهمية: مهم بشكل خاص إذا كانت المواد تحتوي على أي مواد مدرجة

- خيارات الامتثال: إما أن المنتجات لا تحتوي على مواد كيميائية مدرجة أو توفر تحذيرات

كندا

قانون سلامة المنتجات الاستهلاكية كندا

- متطلبات: على غرار المعايير الأمريكية مع بعض الاختلافات

- قانون وضع العلامات النسيج: وضع العلامات ثنائية اللغة (الإنجليزية/الفرنسية)

- متطلبات القابلية للاشتعال: الامتثال لمعايير القابلية للاشتعال

لوائح الاتحاد الأوروبي

الوصول (التسجيل والتقييم والترخيص وتقييد المواد الكيميائية)

- نِطَاق: يقيد العديد من المواد الخطرة في المنتجات الاستهلاكية

- متطلبات: الامتثال لقيود المواد والوثائق

- التحديثات: إضافات منتظمة إلى قائمة المواد المقيدة

توجيه سلامة المنتج العام

- متطلبات: يجب أن تكون المنتجات آمنة للاستخدام المقصود

- توثيق: ملف فني يوضح تقييم السلامة

لائحة وضع العلامات النسيج

- متطلبات: محتوى الألياف في جميع لغات الاتحاد الأوروبي ، تعليمات الرعاية

- التغييرات القادمة: المتطلبات الجديدة المحتملة لمنتجات الحيض

لوائح آسيا والمحيط الهادئ

أستراليا/نيوزيلندا

- معايير سلامة المنتج: الامتثال لمعايير AS/NZS

- قانون المستهلك الأسترالي: متطلبات سلامة المنتج ووضع العلامات

- قانون المنافسة وقانون المستهلك: الحقيقة في متطلبات الإعلان

اليابان

- قانون وضع العلامات على جودة البضائع المنزلية: متطلبات وضع العلامات المحددة

- المعايير الصناعية اليابانية (JIS): معايير الجودة والسلامة

الصين

- معايير GB: الامتثال للمعايير الوطنية للمنسوجات

- التفتيش CIQ: التفتيش المحتمل في الجمارك

- متطلبات وضع العلامات: وضع العلامات على اللغة الصينية

المعايير العالمية الناشئة

لوائح محددة للمنتجات الشهرية

- تقوم العديد من المناطق بتطوير معايير محددة لمنتجات الحيض

- المتطلبات المستقبلية المحتملة لتوحيد الامتصاص

- زيادة التركيز على السلامة الكيميائية في المنتجات الحميمة

للحصول على معلومات حول التنقل في سلسلة التوريد واعتبارات اللوجستية عبر مناطق مختلفة ، تفضل بزيارة دليلنا من المصنع إلى المستودع: فهم موقد ، أوقات الرصاص & الخدمات اللوجستية في مصادر الملابس الداخلية.

كيف تقوم بتقييم معايير المصنع والتصنيع الأخلاقي؟

ضمان التصنيع الأخلاقي مهم بشكل متزايد للمستهلكين وتجار التجزئة. تكافح العديد من الشركات للتحقق من ظروف المصنع والممارسات الأخلاقية ، خاصة عند التصنيع في الخارج.

يتضمن تقييم معايير المصانع تقييم الامتثال الاجتماعي (ممارسات العمل ، وظروف العمل ، والأجور العادلة) ، والمسؤولية البيئية (إدارة النفايات ، واستخدام الموارد) ، وأنظمة إدارة الجودة (معايير الإنتاج المتسقة) ، والشفافية (الاستعداد لتبادل المعلومات والسماح بمراجعة الحسابات).

في وجودنا ، نحن ملتزمون بممارسات التصنيع الأخلاقية والترحيب بمراجعة العميل لمرافقنا. إليك كيفية تقييم معايير المصنع بشكل فعال:

تقييم الامتثال الاجتماعي

المجالات الرئيسية للتقييم

ممارسات العمل

- ساعات العمل الامتثال للقوانين المحلية

- دفع الأجور العادلة وتعويض العمل الإضافي

- حقوق حرية الجمعية

- لا طفل أو عمل قسري

ظروف العمل

- تدابير السلامة في مكان العمل

- إجراءات الطوارئ والمخرج

- التهوية المناسبة والتحكم في درجة الحرارة

- إضاءة كافية وبيئة العمل

رفاهية الموظف

- الوصول إلى الفواصل وفترات الراحة

- تنظيف مرافق مياه الشرب والصرف الصحي

- آليات التظلم

- سياسات مكافحة التحريرة

طرق التحقق

عمليات تدقيق الطرف الثالث

- BSCI (مبادرة الامتثال الاجتماعي التجاري)

- التفاف (الإنتاج المعتمد المسؤول في جميع أنحاء العالم)

- Edex/Smeta (تبادل البيانات الأخلاقية الموردين)

- SA8000 (المساءلة الاجتماعية الدولية)

التقييم المباشر

- زيارات منشأة (تم الإعلان عنها وغير معلنة)

- مقابلات العمال بعيدا عن الإدارة

- مراجعة المستندات (كشوف المرتبات ، سجلات الوقت ، السياسات)

- استشارة أصحاب المصلحة المحليين

تقييم المسؤولية البيئية

المجالات الرئيسية للتقييم

إدارة الموارد

- تدابير استخدام المياه ومحافظة عليها

- كفاءة الطاقة واستخدام الطاقة المتجددة

- مصادر المواد الخام والكفاءة

السيطرة على التلوث

- أنظمة معالجة مياه الصرف الصحي

- ضوابط انبعاث الهواء

- ممارسات الإدارة الكيميائية

إدارة النفايات

- استراتيجيات الحد من نفايات النسيج

- برامج إعادة التدوير

- التعامل مع النفايات الخطرة

طرق التحقق

الشهادات البيئية

- ISO 14001 (الإدارة البيئية)

- نظام Bluesign® (المعيار البيئي الخاص بالنسيج)

- ZDHC (تصريف صفر للمواد الكيميائية الخطرة)

التقييم المباشر

- مراجعة السياسة البيئية

- تفتيش مرفق الضوابط البيئية

- ملاحظة إدارة النفايات

- فواتير الفواتير وسجلات الاستهلاك

تقييم إدارة الجودة

المجالات الرئيسية للتقييم

أنظمة مراقبة الجودة

- فحص المواد الواردة

- فحص الجودة في العملية

- فحص المنتج النهائي

- بروتوكولات الاختبار للامتصاص ومقاومة التسرب

التوثيق والتتبع

- توثيق مصادر المواد

- سجلات الإنتاج

- نتائج اختبار الجودة

- أنظمة تتبع الكثير

تحسين مستمر

- منهجيات حل المشكلات

- تتبع العيوب والتحليل

- برامج تدريب الموظفين

- صيانة المعدات

طرق التحقق

شهادات الجودة

- ISO 9001 (أنظمة إدارة الجودة)

- معايير الجودة الخاصة بالصناعة

التقييم المباشر

- مراجعة يدوي الجودة

- مراقبة أرضية الإنتاج

- اختبار مرفق تقييم

- تحليل معدل العيب

قائمة مراجعة تقييم المصنع

عند تقييم شركاء التصنيع المحتملين ، استخدم قائمة المراجعة هذه:

| فئة | الأسئلة الرئيسية |

|---|---|

| الامتثال الاجتماعي |

• ما هي شهادات الامتثال الاجتماعية التي يحتفظون بها؟ • متى كانت آخر مراجعة لجهة خارجية؟ • هل هم على استعداد لتبادل تقارير التدقيق؟ • ما هو معدل دوران الموظف؟ |

| الممارسات البيئية |

• ما هي أنظمة الإدارة البيئية الموجودة؟ • كيف يتعاملون مع نفايات مياه الصرف الصحي والمنسوجات؟ • هل لديهم برامج كفاءة الطاقة؟ • ما هي بروتوكولات الإدارة الكيميائية التي يتبعونها؟ |

| أنظمة الجودة |

• ما هي شهادات الجودة التي يحافظون عليها؟ • ما هي معدات الاختبار التي لديهم في المنزل؟ • كيف يتعاملون مع مشكلات الجودة والعيوب؟ • هل يمكنهم توفير مقاييس أداء عالية الجودة؟ |

| الشفافية |

• هل هم على استعداد للسماح بزيارات المنشأة؟ • هل يكشفون عن جميع مواقع الإنتاج (بما في ذلك المقاولين من الباطن)؟ • هل سيوفرون الوصول إلى العمال للمقابلات؟ • كيف ينقلون تحديات الإنتاج؟ |

للحصول على معلومات حول تطوير خط الملابس الداخلية الخاصة بك مع الشركات المصنعة الأخلاقية ، استكشف موردنا على علامتك التجارية ، منتجك: الدليل الكامل للملصقات الخاصة (OEM/ODM) تصنيع الملابس الداخلية.

كيف تضمن الامتثال والجودة المستمرة؟

الشهادة الأولية هي مجرد البداية. تفشل العديد من الشركات في تنفيذ أنظمة لمراقبة الامتثال المستمرة ، مما يؤدي إلى انزلاق المعايير مع مرور الوقت.

يتطلب ضمان الامتثال المستمر تنفيذ بروتوكولات الاختبار العادية (اختبار المواد ، واختبار المنتج النهائي ، واختبار متانة الغسيل) ، وإجراء عمليات تدقيق في المصنع الدورية (كل من الزيارات المجدولة والمفاجأة) ، والحفاظ على أنظمة توثيق واضحة ، وإنشاء إجراءات الإجراءات التصحيحية لمعالجة أي مشكلات تنشأ.

في الحصول على أنظمة شاملة للحفاظ على معايير الامتثال والجودة خلال عمليات التصنيع الخاصة بنا. إليك نهجنا في الامتثال المستمر:

بروتوكولات الاختبار العادية

اختبار المواد

تكرار: كل قطعة واردة

الاختبارات التي أجريت:

- التحقق من محتوى الألياف

- فحص المواد المقيدة

- الخصائص الفيزيائية (الوزن ، الامتداد ، الانتعاش)

- ثبات اللون

اختبار الإنتاج

تكرار: أثناء الإنتاج على فترات محددة

الاختبارات التي أجريت:

- التحقق من قدرة الامتصاص

- اختبار مقاومة التسرب

- فحوصات جودة البناء

- الاستقرار الأبعاد

اختبار المنتج النهائي

تكرار: كل مجموعة إنتاج

الاختبارات التي أجريت:

- اختبار الامتصاص الكامل

- غسل أخذ عينات المتانة

- فحص الجودة النهائي

- سلامة التعبئة والتغليف

جدول التدقيق والتفتيش

عمليات التدقيق الداخلية

تكرار: شهريًا

مجالات التركيز:

- عملية الإنتاج الالتزام

- تنفيذ مراقبة الجودة

- معايير السلامة والامتثال

- اكتمال الوثائق

عمليات تدقيق الطرف الثالث

تكرار: سنويًا أو حسب الاقتضاء بالشهادات

الأنواع:

- تدقيق الامتثال الاجتماعي

- عمليات التدقيق البيئية

- تدقيق نظام إدارة الجودة

- تجديد الشهادات المحددة

تدقيق العميل

تكرار: حسب طلب العملاء

يقترب:

- سياسة الباب المفتوح لزيارات العميل

- مشاركة شفافة للوثائق

- الوصول إلى مناطق الإنتاج

- مقابلات العمال حسب الاقتضاء

أنظمة التوثيق

الحفاظ على الوثائق الشاملة أمر ضروري لإثبات الامتثال:

- شهادات المواد: وثائق لجميع المواد الواردة

- التقارير اختبار: نتائج جميع الاختبارات التي أجريت

- سجلات الإنتاج: وثائق تصنيع مفصلة

- وثائق الشهادة: الشهادات الحالية وتقارير التدقيق

- سجلات التدريب: توثيق تدريب الموظفين

- تقارير الإجراءات التصحيحية: سجلات القضايا والقرارات

إجراءات الإجراء التصحيحي

عندما يتم تحديد المشكلات ، يضمن النهج المنهجي الدقة السليم:

- إصدار الوثائق: تسجيل مفصل للمشكلة

- تحليل السبب الجذري: تحديد السبب الأساسي

- خطة العمل التصحيحية: خطوات محددة لمعالجة المشكلة

- تطبيق: تنفيذ الإجراءات التصحيحية

- تَحَقّق: تأكيد فعالية الإجراءات

- التدابير الوقائية: تنفيذ الأنظمة لمنع التكرار

تكنولوجيا إدارة الامتثال

تعمل إدارة الامتثال الحديثة على الاستفادة من التكنولوجيا:

- أنظمة الوثائق الرقمية: حفظ السجلات المركزية

- رمز الاستجابة السريعة تتبع: ربط المنتجات بسجلات الإنتاج

- معدات الاختبار الآلية: ضمان طرق اختبار متسقة

- برنامج إدارة الامتثال: تتبع الشهادات والتجديد

للحصول على معلومات مفصلة حول معايير مراقبة الجودة وبروتوكولات الاختبار ، تفضل بزيارة موردنا الشامل على ضمان تميز المنتج: مراقبة الجودة & معايير التصنيع لمصادر الملابس الداخلية.

خاتمة

يعد التنقل في الامتثال والشهادات ومعايير المصنع أمرًا ضروريًا لمصادر الملابس الداخلية بالثقة. من خلال فهم الشهادات ذات الصلة واللوائح الإقليمية ومعايير التصنيع الأخلاقي ومتطلبات الامتثال المستمرة ، يمكن للشركات حماية سمعة علامتها التجارية مع تقديم منتجات آمنة وعالية الجودة للمستهلكين.

للحصول على نظرة عامة شاملة على فئة الملابس الداخلية بأكملها ، بما في ذلك اعتبارات التصنيع وفرص الشراكة ، تفضل بزيارة دليل B2B النهائي للمصادر & بيع الفترة الداخلية.

في الحصول على التزامنا بالامتثال والتصنيع الأخلاقي ، كان أمرًا أساسيًا لنجاحنا في إنتاج أكثر من مليوني وحدة داخلية للملابس الداخلية سنويًا لتجار التجزئة الرئيسيين مع الحفاظ على أعلى معايير سلامة المنتج وجودةها.

الأسئلة المتداولة (الأسئلة الشائعة)

ما هي أهم شهادة للملابس الداخلية الفترة؟

يُعتبر Oeko-Tex Standard 100 عمومًا هو أكثر الشهادات الأساسية للملابس الداخلية الفترة ، حيث تتحقق من أن جميع المكونات خالية من المواد الضارة-أمرًا حرجة للمنتجات ذات التلامس المطول مع المناطق البشرة الحساسة.

كم مرة يجب اختبار الملابس الداخلية للامتثال؟

يجب أن يحدث اختبار المواد لكل مجموعة جديدة من المواد ، في حين يجب إجراء اختبار المنتج النهائي لكل تشغيل إنتاج. تتبع مراجعات الامتثال الشاملة ، بما في ذلك تجديد الشهادات ، الدورات السنوية.

ما الفرق بين شهادات BSCI و WRAP؟

يشهد كلاهما على التصنيع الأخلاقي ، لكن BSCI (مبادرة الامتثال الاجتماعي التجاري) أكثر شيوعًا في الأسواق الأوروبية ويتبع نهج التحسين المستمر ، في حين أن Wrap (الإنتاج المعتمد المسؤول في جميع أنحاء العالم) أكثر انتشارًا في أسواق أمريكا الشمالية ويستخدم نظام مستوى الشهادات.

كيف يمكنني التحقق من مطالبات PFAS الخالية من PFAS في الملابس الداخلية؟

طلب تقارير اختبار محددة باستخدام طرق مثل LC-MS/MS (كروماتوجرافيا سائلة مع مطياف الكتلة الترادفية) التي يمكنها اكتشاف مركبات PFAS عند مستويات منخفضة. يجب إجراء الاختبارات من قبل مختبرات الجهات الخارجية المعتمدة على المنتجات النهائية.

ما هي الوثائق التي يجب أن أطلبها من شركاء التصنيع المحتملين؟

اطلب نسخًا حالية من الشهادات ذات الصلة (Oeko-Tex ، ISO ، الامتثال الاجتماعي) ، تقارير تدقيق الطرف الثالث الأخير ، تقارير الاختبار عن منتجات مماثلة ، وسياساتها المكتوبة حول مراقبة الجودة ، والمسؤولية الاجتماعية ، والإدارة البيئية.

كيف تختلف اللوائح الإقليمية للملابس الداخلية الفترة؟

تشمل الاختلافات الرئيسية متطلبات وضع العلامات (اللغة ، المحتوى) ، القيود الكيميائية (الوصول إلى الاتحاد الأوروبي أكثر صرامة من اللوائح الأمريكية) ، معايير قابلية التشهير ، ومتطلبات محددة للمنتجات التي يتم تسويقها إلى المراهقين أو الأطفال.