Activewear & Yoga Wear Technology & Materials: A Buyer's Guide to Performance Fabrics, Construction & Durability?

Selecting the right materials and construction techniques for activewear can be overwhelming. Many businesses choose inappropriate fabrics or inadequate construction methods, resulting in products that pill, lose shape, or fail to perform as promised, damaging brand reputation.

High-quality activewear combines technical performance fabrics with specialized construction techniques. Key attributes include four-way stretch for unrestricted movement, moisture-wicking to keep skin dry, durability through multiple washes, and strategic seam placement to prevent chafing. Superior yoga wear adds considerations for opacity during poses and gentle compression that maintains shape.

As a manufacturer who's helped develop activewear for major brands, I've gained deep insights into what makes these products perform. At HAVING, we've tested countless material combinations and construction techniques to create activewear that performs reliably while remaining comfortable. Let me share what we've learned about the critical components that make activewear effective.

What Makes Performance Fabrics Different from Regular Fabrics?

Many businesses underestimate the technical requirements of activewear fabrics. Understanding these differences is essential for creating products that truly perform during physical activity.

Performance fabrics differ from regular apparel fabrics in four key ways: moisture management (wicking sweat away from the body), stretch and recovery (maintaining shape during movement), durability (withstanding abrasion and frequent washing), and specialized finishes (such as anti-odor or UV protection). These technical properties require specific fiber compositions and construction methods.

When we develop activewear at HAVING, we focus on these technical properties that separate performance fabrics from standard apparel materials:

Moisture Management

Effective moisture management is perhaps the most defining characteristic of performance fabrics:

Wicking Mechanism

Performance fabrics use capillary action to draw moisture away from the skin and spread it across the fabric's outer surface, where it can evaporate quickly. This process involves:

- Hydrophobic Inner Layer: Repels moisture against the skin

- Hydrophilic Outer Layer: Attracts moisture to the fabric surface

- Capillary Pathways: Channels that transport moisture outward

Fabric Constructions for Moisture Management

| Construction Type | Wicking Performance | Best For |

|---|---|---|

| Microfiber Polyester | Excellent | High-intensity activities |

| Mechanical Wicking (textured yarns) | Very Good | Moderate activities, everyday wear |

| Chemical Treatments | Good (diminishes with washing) | Budget-friendly options |

| Natural Wicking (wool, bamboo) | Moderate to Good | Eco-conscious consumers, sensitive skin |

Stretch and Recovery

The ability to stretch with movement and return to original shape is crucial for activewear performance:

Four-Way vs. Two-Way Stretch

- Four-Way Stretch: Extends both horizontally and vertically, providing maximum freedom of movement. Essential for yoga, dance, and activities requiring full range of motion.

- Two-Way Stretch: Extends in one direction only (typically horizontally). Suitable for activities with more limited movement patterns.

Recovery Factors

Quality activewear must return to its original shape after stretching. Key factors include:

- Elastane Content: Typically 15-25% for optimal recovery

- Fiber Quality: Premium elastane maintains recovery longer

- Construction Method: Knit structures affect recovery performance

- Heat Setting: Proper manufacturing processes ensure lasting recovery

Durability Considerations

Activewear faces unique durability challenges:

- Abrasion Resistance: Withstanding friction from movement and equipment

- Pilling Resistance: Maintaining smooth surface despite repeated wear

- Colorfastness: Retaining color despite sweat, washing, and UV exposure

- Wash Durability: Maintaining performance properties through frequent laundering

Specialized Performance Finishes

Modern activewear often incorporates additional performance technologies:

- Anti-Odor/Antimicrobial: Silver ions, zinc compounds, or natural alternatives

- UV Protection: UPF ratings for outdoor activities

- Thermoregulation: Phase-change materials that help regulate body temperature

- Water/Wind Resistance: DWR (Durable Water Repellent) treatments for outdoor use

For a comprehensive overview of the entire activewear category, including market trends and business opportunities, visit our Ultimate B2B Guide to Sourcing & Selling Activewear & Yoga Wear.

What Fabrics Work Best for Different Activewear Applications?

Selecting the right fabric for specific activities is crucial for product success. Many businesses apply a one-size-fits-all approach that fails to address the unique demands of different exercises.

Different activities require specialized fabric properties: high-intensity workouts need maximum moisture management and durability; yoga demands excellent stretch, recovery, and opacity; outdoor activities require UV protection and temperature regulation; while athleisure pieces balance performance with comfort and style for everyday wear.

At HAVING, we match fabric properties to specific activity requirements. Here's our guide to selecting the right materials for different applications:

High-Intensity Training/Running

These activities generate significant heat and sweat, requiring:

- Ideal Fabrics: Lightweight polyester/elastane blends (80-85% polyester, 15-20% elastane)

- Key Properties: Superior moisture-wicking, quick-drying, lightweight feel

- Construction: Mechanical wicking structures, mesh panels for ventilation

- Weight Range: 140-200 GSM (grams per square meter)

- Additional Features: Anti-odor treatments, reflective elements for visibility

Yoga and Studio Activities

These practices demand fabrics that perform during varied movements and poses:

- Ideal Fabrics: Nylon/elastane blends (75-80% nylon, 20-25% elastane)

- Key Properties: Four-way stretch, excellent recovery, opacity when stretched

- Construction: Brushed interior for soft feel, compressive but not restrictive

- Weight Range: 220-280 GSM for leggings, 180-220 GSM for tops

- Additional Features: Matte finish, minimal seams to prevent irritation

Outdoor Activities

Environmental exposure creates unique fabric requirements:

- Ideal Fabrics: Durable polyester blends, sometimes with nylon reinforcement

- Key Properties: UV protection, abrasion resistance, quick-drying

- Construction: Tighter weaves or knits for durability, reinforced stress points

- Weight Range: Varies by season (140-180 GSM summer, 200-300 GSM winter)

- Additional Features: UPF ratings, DWR treatments, antimicrobial properties

Athleisure/Lifestyle

These pieces must balance performance with everyday comfort:

- Ideal Fabrics: Soft polyester/elastane or cotton/elastane blends

- Key Properties: Comfort, stretch, casual appearance with performance benefits

- Construction: Brushed surfaces, heathered looks, fashion-forward textures

- Weight Range: 200-320 GSM for bottoms, 150-220 GSM for tops

- Additional Features: Wrinkle resistance, easy care, crossover styling

Fabric Comparison Chart

| Fabric Type | Pros | Cons | Best For |

|---|---|---|---|

| Polyester/Elastane | Excellent moisture management, durability, color retention | Less breathable than natural fibers, potential for odor retention | High-intensity training, running, durability-focused items |

| Nylon/Elastane | Superior stretch and recovery, soft hand feel, durability | Higher cost, less moisture-wicking than polyester | Yoga, studio activities, compression pieces |

| Cotton/Elastane | Natural feel, breathability, comfort | Poor moisture management, slower drying, less durability | Light activities, athleisure, lifestyle pieces |

| Recycled Polyester Blends | Sustainability story, similar performance to virgin polyester | Slightly higher cost, potential consistency challenges | Eco-conscious brands, sustainability positioning |

For insights on building a complete activewear product line with appropriate fabrics for different activities, visit our guide on Curating Your Collection: A B2B Guide to Activewear & Yoga Wear Styles, Functions & Material Options.

What Construction Techniques Are Essential for Quality Activewear?

Construction methods significantly impact activewear performance and durability. Many businesses focus solely on fabric selection while overlooking the critical role of proper construction techniques.

Quality activewear construction requires specialized techniques: flatlock or coverstitch seams to prevent chafing, strategic seam placement to enhance movement, reinforcement at stress points, and proper stitch density for durability during stretch. For yoga wear, additional considerations include gusset construction for mobility and waistband design for stay-put performance.

At HAVING, our "body-before-fabric" philosophy guides our construction approach. We prioritize techniques that enhance comfort and performance during movement:

Seam Construction

The right seaming techniques are crucial for comfort and durability:

Flatlock Seams

- Construction: Two fabric edges butted together and stitched flat

- Benefits: Minimal bulk, reduced chafing, comfortable against skin

- Best For: Areas with direct skin contact, compression garments

- Considerations: Requires specialized machinery, higher production cost

Coverstitch

- Construction: Visible parallel stitching on outside, looped thread on inside

- Benefits: Stretch capability, clean finish, durability

- Best For: Hems, necklines, areas needing stretch

- Considerations: Professional appearance, moderate production cost

Overlock/Serged Seams

- Construction: Fabric edges sewn together and finished in one operation

- Benefits: Production efficiency, adequate stretch

- Best For: Non-critical areas, internal construction

- Considerations: Can cause chafing if used in sensitive areas

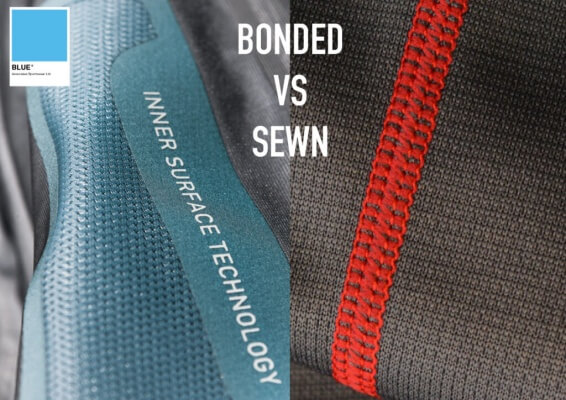

Bonded/Welded Seams

- Construction: Fabrics fused together using heat or adhesive

- Benefits: Seamless appearance, waterproofing potential, no chafing

- Best For: Premium products, waterproof items, ultra-lightweight pieces

- Considerations: Highest production cost, requires specialized equipment

Strategic Seam Placement

Where seams are placed significantly impacts comfort and performance:

- Movement Mapping: Placing seams away from high-friction areas

- Body Contouring: Using seams to enhance fit and provide support

- Stress Distribution: Strategic placement to distribute tension

- Visual Effect: Using seams to create slimming or enhancing effects

Critical Construction Elements

Waistband Construction

Waistbands are crucial for comfort and function:

- High-Rise vs. Mid-Rise: Different construction needs based on height

- Internal Elastic: Provides support without direct skin contact

- Powermesh Lining: Adds gentle compression and support

- Gusset Construction: Diamond or oval shape for maximum mobility

Sports Bra Construction

Support and comfort require specialized techniques:

- Encapsulation vs. Compression: Different construction for different support needs

- Strap Design: Reinforcement for weight-bearing areas

- Band Construction: Wide elastic or fabric bands for support

- Removable Cups: Construction allowing for optional modesty pads

Quality Indicators in Construction

When evaluating activewear construction quality, look for:

| Quality Indicator | What to Look For | Why It Matters |

|---|---|---|

| Stitch Density | 8-12 stitches per inch | Ensures seam strength during stretch |

| Thread Selection | Nylon core spun or textured polyester | Provides stretch and durability |

| Seam Alignment | Precise matching at intersections | Indicates attention to detail and quality control |

| Reinforcement | Bar tacks or extra stitching at stress points | Prevents seam failure during use |

For information on quality control standards and testing protocols for activewear construction, visit our resource on Ensuring Product Excellence: Quality Control & Manufacturing Standards for Activewear & Yoga Wear Sourcing.

How Do You Evaluate Activewear Quality and Performance?

Assessing activewear quality can be challenging without specialized knowledge. Many businesses lack clear criteria for evaluating samples and production quality, leading to inconsistent products and customer disappointment.

Quality activewear should be evaluated on multiple criteria: fabric performance (moisture management, stretch recovery, opacity), construction quality (seam strength, stitch consistency, reinforcement), durability (pilling resistance, colorfastness, wash performance), and comfort (next-to-skin feel, movement compatibility, weight appropriateness).

At HAVING, we've developed comprehensive quality evaluation protocols for activewear. Our experience manufacturing for major brands has taught us what separates exceptional products from mediocre ones. Here's how we recommend evaluating activewear quality:

Objective Testing Methods

Several standardized tests can objectively measure activewear performance:

Moisture Management Testing

- Vertical Wicking Test: Measures how quickly moisture travels up a fabric strip

- Moisture Management Tester (MMT): Evaluates multi-dimensional wicking

- Drying Rate Test: Measures how quickly fabric dries after wetting

Stretch and Recovery Testing

- Stretch Percentage: Measures maximum extension before fabric damage

- Recovery Rate: Evaluates how completely fabric returns to original dimensions

- Repeated Stretch Testing: Simulates multiple wearings and washings

Durability Testing

- Martindale Abrasion Test: Measures resistance to surface wear

- Pilling Resistance: Evaluates tendency to form surface fuzz balls

- Colorfastness: Tests color retention after washing, sweating, and light exposure

- Dimensional Stability: Measures shrinkage or stretching after washing

Opacity Testing

Particularly important for yoga wear:

- Stretch Opacity: Testing transparency when fabric is extended

- Bend Test: Evaluating coverage during deep bending positions

- Light Box Testing: Measuring light transmission through fabric

Practical Evaluation Techniques

Beyond lab testing, practical evaluation provides valuable insights:

Movement Testing

- Wear Testing: Having actual users perform activities in the garments

- Range of Motion Assessment: Checking for restriction during movement

- Ride-Up/Down Evaluation: Testing if garments stay in place during activity

Comfort Assessment

- Hand Feel: Evaluating softness and texture against skin

- Weight Appropriateness: Ensuring fabric weight matches intended activity

- Pressure Point Identification: Checking for areas of discomfort during wear

Construction Examination

- Seam Strength: Testing resistance to popping during stretch

- Stitch Consistency: Evaluating evenness and tension

- Trim Security: Checking attachment of hardware, labels, and decorative elements

Common Quality Issues to Watch For

Based on our manufacturing experience at HAVING, these are the most common quality problems to identify:

| Quality Issue | Identification Method | Potential Impact |

|---|---|---|

| Pilling | Visual inspection after wear/wash, abrasion testing | Poor appearance, reduced customer satisfaction |

| Seam Failure | Stretch testing, movement assessment | Product failure, returns, brand damage |

| Color Bleeding | Wash testing, crocking test | Customer complaints, damaged other garments |

| Transparency Issues | Stretch opacity testing, bend testing | Customer embarrassment, returns, negative reviews |

| Loss of Compression | Recovery testing after multiple washes | Reduced performance, baggy appearance |

For information on developing your own private label activewear line with optimal quality standards, visit our detailed resource: Your Brand, Your Product: The Complete Guide to Private Label (OEM/ODM) Activewear & Yoga Wear Manufacturing.

What Innovations Are Shaping the Future of Activewear Materials?

The activewear materials landscape continues to evolve rapidly. Staying informed about emerging technologies and innovations is essential for businesses looking to maintain competitive advantage.

The future of activewear is being shaped by several key innovations: sustainable material developments (recycled and biodegradable fibers), smart textiles with integrated technology, advanced thermoregulation fabrics, and natural performance materials that combine eco-friendliness with technical function.

At HAVING, we're constantly researching and developing new approaches to activewear materials. Our R&D team focuses on innovations that solve real consumer pain points while improving sustainability. Here are the key developments we're seeing:

Sustainable Material Innovations

Eco-friendly alternatives are rapidly advancing:

- Recycled Polyester Evolution: Improved processing creating performance parity with virgin materials

- Bio-Based Synthetics: Partially plant-derived polyester and nylon alternatives

- Biodegradable Elastane Alternatives: Addressing the least sustainable component in stretch fabrics

- Natural Performance Fibers: Enhanced cotton, hemp, and bamboo with engineered performance

Smart and Responsive Textiles

Technology integration is creating new possibilities:

- Temperature-Responsive Fabrics: Materials that adapt to body heat and environmental conditions

- Moisture-Triggered Ventilation: Structures that open when moisture is detected

- Embedded Sensors: Fabrics with integrated fitness tracking capabilities

- Energy-Generating Textiles: Materials that harvest energy from movement

Advanced Performance Technologies

New approaches to core performance needs:

- Dry-Dye Technology: Waterless dyeing processes reducing environmental impact

- Multi-Functional Finishes: Single treatments providing multiple benefits (antimicrobial + cooling)

- Engineered Compression: Zone-specific compression levels in single garments

- Enhanced Natural Materials: Treatments giving natural fibers performance properties

Future Outlook

Based on our industry experience and R&D at HAVING, we anticipate several key developments in activewear materials over the next 3-5 years:

- Mainstream Adoption of Recycled Materials: Recycled content becoming standard rather than premium

- Biodegradable Synthetic Blends: Addressing end-of-life concerns for performance fabrics

- Simplified Supply Chains: Technologies reducing processing steps and environmental impact

- Personalization Technologies: Materials adaptable to individual body types and preferences

For insights on how these innovations might affect your product development strategy, explore our guide on The Business Case for Sustainable Activewear & Yoga Wear: Meeting Consumer Demand & Enhancing Brand Value.

Conclusion

Understanding activewear and yoga wear technology and materials is essential for creating products that truly perform and meet consumer expectations. By selecting appropriate fabrics for specific activities, implementing proper construction techniques, and establishing rigorous quality evaluation methods, businesses can develop activewear that builds brand loyalty and drives growth.

At HAVING, we combine technical expertise with manufacturing capability to create activewear that performs consistently while meeting evolving consumer demands for both function and sustainability.

Frequently Asked Questions (FAQ)

What's the difference between polyester and nylon for activewear?

Polyester typically offers superior moisture management and color retention, while nylon provides better stretch, recovery, and a softer hand feel. Polyester is often preferred for high-intensity activities generating significant sweat, while nylon excels in yoga and studio applications where stretch and comfort are paramount.

How much elastane should quality activewear contain?

Most high-performance activewear contains 15-25% elastane (spandex/Lycra). Compression garments may contain up to 30%, while lighter-support items might use 10-15%. The percentage affects both stretch capability and recovery performance.

What causes pilling in activewear and how can it be prevented?

Pilling occurs when short fibers work loose, tangle, and form small balls on the fabric surface. Prevention strategies include using longer staple fibers, tighter knit constructions, appropriate fiber blends, and special anti-pill finishes during manufacturing.

How can I test if leggings will be squat-proof?

Perform a bend test by having someone wear the leggings and bend forward in good lighting. For production testing, use standardized opacity testing with a light box behind stretched fabric. Quality yoga leggings should maintain at least 70-80% opacity when stretched to maximum extension.

What's the most durable construction method for activewear seams?

Flatlock seams offer the best combination of durability, comfort, and performance for most activewear applications. For maximum durability in extreme stress areas, reinforced flatlock seams with additional bartacking provide superior strength.

How do sustainable materials compare to conventional ones in performance?

Modern recycled polyester and nylon can match conventional materials in performance, with differences of less than 5% in key metrics like moisture-wicking and durability. The performance gap has narrowed significantly in recent years as recycling technology has improved.