A Manufacturer's Guide: How to Engineer a High-Impact Sports Bra That Actually Works?

Your brand wants to enter the lucrative high-impact sports bra market. You've designed a product that looks strong, using thick fabrics and a tight fit. But customer feedback is brutal: it either offers poor support during a run, or it's so restrictive and uncomfortable that no one wants to wear it.

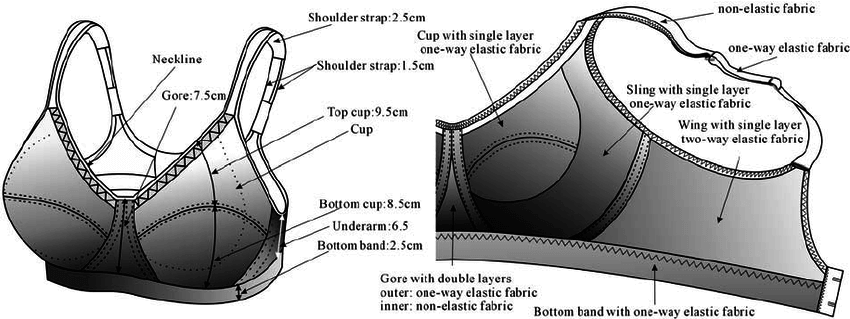

Creating a truly effective high-impact sports bra is an act of engineering, not just design. It requires a deep understanding of biomechanics and the four pillars of support: the scientific method (compression vs. encapsulation), the anchor (the band), the distribution system (straps and back), and the performance material (the fabric matrix).

High-impact support is a science. Simply layering heavy, compressive fabric is a rookie mistake I see all too often. The result is a garment that constricts breathing without actually preventing damaging breast movement. As a manufacturer of performance apparel, my team doesn't just see a bra; we see a piece of technical equipment. At HAVING (China) Ltd., our "body-before-fabric" philosophy forces us to think like engineers. How does the body move? Where do forces need to be absorbed? This guide is a look inside that engineering process. It’s how you move from a bra that looks strong to one that is strong.

Pillar #1: Are You Just Squeezing, or Are You Supporting?

Many brands believe that "high support" simply means "tighter." They create a single, tight layer of fabric that flattens the chest, assuming this compression is enough to stop movement during high-impact activities like running or HIIT.

This is the most common design flaw. True support comes from two distinct scientific methods: "Compression" (squeezing) and "Encapsulation" (separating and securing each breast). The most effective high-impact sports bras for larger cup sizes use a sophisticated combination of both.

Understanding this difference is the first step to becoming a serious player in the performance market. Compression is effective for smaller cup sizes (A/B cup) as it works by pressing the breast tissue flat against the chest wall to reduce movement. However, for larger cup sizes (C cup and above), compression alone is often uncomfortable and insufficient. Encapsulation is the technology used in everyday underwire bras—it lifts and separates each breast into its own structured cup. When we engineer a high-impact bra for a client, we often create a hybrid. We build a bra with fully separated, molded cups (encapsulation) and then overlay it with a supportive, compressive outer layer. This combination provides a powerful defense against movement without sacrificing shape or comfort.

The Science of Support

| Support Method | How It Works | Best For |

|---|---|---|

| **Compression** | Squeezes breasts against the chest wall. Simple, single-layer construction. | Low to medium impact activities; smaller cup sizes (A-B). |

| **Encapsulation** | Lifts and supports each breast in a separate, structured cup. More complex construction. | Low to medium impact activities; all cup sizes, especially C+. Offers a more natural shape. |

| **Combination** | Uses individual cups (Encapsulation) within a compressive outer shell (Compression). | High-impact activities (running, HIIT, sports); all cup sizes, essential for C+. The gold standard for performance. |

Pillar #2: Is Your Band the Anchor or a Weak Link?

You've focused all your attention on the cups and the straps. You've made the band from the same comfortable, stretchy fabric as the rest of the bra, assuming it's just there to hold things together.

The band is not an accessory; it is the chassis of the entire garment. It should provide up to 80% of the bra's total support. An effective band must be made from a wide, low-stretch, high-modulus elastic to create a firm, stable "anchor" from which the rest of the support system can function.

When a brand sends us a tech pack for a new sports bra, the first thing our engineers look at is the band specification. If it's weak, we know the design will fail, no matter how good the rest of it is. The band is what stops the entire bra from moving up and down with the body during impact. A flimsy band will ride up, causing the straps to dig in and the cups to lose their supportive position. We advise our clients to use a distinct, powerful elastic for the band—at least one inch wide, and often wider for larger sizes. The feel should be plush on the inside for comfort, but the structure must be firm. It needs to fit snugly around the ribcage, like a foundation. Without a strong foundation, the whole house will collapse.

Pillar #3: Are Your Straps Bearing the Burden?

Your customers are complaining about sore shoulders and red marks after a workout. You might think this is a necessary evil of a high-support bra, a sign that it's "working."

This is a classic symptom of a failed anchor band. If the straps are digging in, it means they are being forced to do the support work that the band should be doing. Well-designed straps are for stabilization and pressure distribution, not heavy lifting. Their design, width, and material are critical for comfort, not primary support.

The straps are the final piece of the support puzzle. Their job is to hold the cups in place and distribute the remaining load comfortably across the shoulders. A wider, padded strap is essential for larger cup sizes to spread the pressure over a larger surface area. The back design is also crucial. A "racerback" or "T-back" design is excellent for activities with a lot of arm movement (like running or tennis) because it allows the shoulder blades (scapulae) to move freely. A more traditional "U-back" (like a normal bra) can offer great support and is often easier to get on and off. As part of our OEM/ODM services, we often create multiple prototypes to test how different back designs interact with the overall support system, ensuring the final product is a perfect balance of stability and freedom of movement.

Pillar #4: Is Your Fabric Just Wicking Sweat or Actively Supporting?

You've chosen a fabric that is "moisture-wicking" and has good stretch. But during a high-intensity workout, the bra starts to feel baggy, and the support seems to fade.

For high-impact, the fabric is an active performance component. You must look beyond basic wicking and select a material with a high "stretch recovery rate" and excellent "modulus." This ensures the fabric can stretch to accommodate movement but then instantly snap back to its original shape to provide consistent support, workout after workout.

This is where material science becomes critical. "Stretch" is easy to find. "Recovery" is what you pay for. A cheap fabric will stretch, but it won't snap back effectively. This is called "growth," and it's why a low-quality sports bra feels loose and unsupportive after 20 minutes of running. When we source fabrics for performance lines like our bras and high-tech shapewear, we look at the lab data. We need a fabric with a high percentage of quality elastane (like Lycra®) and a dense, powerful knit structure. We also increasingly use "body-mapping," a design philosophy where we place different fabrics in different zones: a high-power, low-stretch fabric for the main support zones, and a more breathable, open-mesh fabric in high-sweat zones like the back and under the bust.

The Fabric Performance Matrix

- Stretch & Recovery: The ability to stretch and instantly return to form. Critical for consistent support.

- Modulus: A measure of the fabric's resistance to stretching. A high-modulus fabric feels more "powerful" and provides better compression.

- Moisture Wicking: The ability to pull sweat away from the skin to the fabric's surface to evaporate.

- Durability: The ability to withstand repeated washing and wear without losing its shape or supportive properties.

Conclusion

An effective high-impact sports bra is a sophisticated piece of engineering where science, structure, and materials converge. Partnering with a manufacturer who understands these four pillars is the only way to transform your design from a blueprint into a best-selling performance product.

Frequently Asked Questions (FAQ)

1. Is underwire necessary for a high-impact sports bra?

While many modern designs are wire-free, underwire is still a very effective tool for encapsulation, especially for larger cup sizes (DD+). A flexible, well-cushioned underwire can provide superior separation and lift that is difficult to achieve with fabric alone, leading to better motion control.

2. What does "body-mapping" mean in sportswear design?

Body-mapping is a design technique where different fabrics or knit structures are placed on different parts of a garment based on the body's needs in that area. For a sports bra, this means using high-support panels on the front and sides, and highly breathable mesh panels in high-sweat zones like the center back.

3. Why do some sports bras have a hook-and-eye closure like a regular bra?

A hook-and-eye closure allows for a much more precise and adjustable fit around the band. Since the band provides most of the support, being able to get it perfectly snug is a major performance advantage. It also makes a very firm, compressive bra much easier to put on and take off.

4. What is the best material for sports bra pads or inserts?

The best pads are made from perforated or molded foam that is engineered to be breathable. Avoid thick, non-porous foams that trap sweat and heat against the skin. Some high-end pads are also infused with anti-odor or cooling technologies.