How to Engineer a "Seamless Feel" in Cut-and-Sew Lingerie: A Manufacturer's Guide

You love the design freedom of traditional cut-and-sew lingerie—the intricate lace panels, the perfect shaping. But you're haunted by the biggest complaint from customers: scratchy, digging seams that ruin the entire experience. You're stuck, believing that true "seamless comfort" is impossible for your designs.

This is a common myth. By engineering four key details—the seam construction, the thread, the trims, and the labels—you can achieve a luxurious "seamless feel" in a high-quality cut-and-sew garment. Comfort is not an accident; it is a result of precise manufacturing technology.

As a manufacturer, I often hear designers say they have to choose between the beauty of cut-and-sew and the comfort of seamless. This is a false choice. The truth is, that annoying, scratchy feeling doesn't come from the fact that a garment has seams; it comes from how those seams are constructed. At HAVING (China) Ltd., our "body-before-fabric" philosophy drives us to obsess over these details. We believe comfort can be engineered into any design. This guide will reveal the four key technologies we use to eliminate irritation and elevate the comfort of cut-and-sew lingerie to a whole new level.

Tech #1: Are Your Seams Part of the Problem or the Solution?

Look inside most standard lingerie. You'll find a bulky, raised seam called an "overlock" stitch along the sides. While strong, this ridge of thread is a primary source of friction and irritation against the skin.

The first revolution in comfort is the "Flatlock Seam." Unlike a traditional overlock that creates a raised edge, a flatlock seam is constructed so that the fabric edges lie perfectly flat against each other. This fundamentally eliminates the friction and digging sensation at critical areas like the side seams and leg openings.

The visual and tactile difference is astounding. A flatlock seam feels almost like there's no seam at all. It requires a highly specialized sewing machine and a more skilled operator, so it's a more expensive process. This is why you won't find it on cheap, mass-market goods. When a client comes to us with a design for a premium pair of panties or a bodysuit, this is one of the first upgrades we suggest. It is a tangible, immediately noticeable improvement in comfort that justifies a higher retail price. It’s a clear signal to the customer that this is a high-quality, thoughtfully designed garment.

The Seam Showdown

| Seam Type | Construction | Comfort Level |

|---|---|---|

| **Standard Overlock** | Joins fabric with a raised, serged edge. Fast and strong. | Can feel bulky and cause friction or irritation against the skin. |

| **Flatlock Seam** | A complex stitch that joins fabric edge-to-edge, creating a perfectly flat seam. | Superior comfort. Eliminates the "seam feel" and prevents chafing. The hallmark of high-performance apparel. |

Tech #2: Is Your Thread a Hidden Irritant?

You've chosen the softest modal fabric, but customers still complain about itchiness, especially around the seams. The fabric is perfect, so what's the problem? The culprit is often the thread itself.

Standard, cheap polyester thread is a hidden killer of comfort. It can be coarse and cause micro-abrasions on the skin. The solution is to use premium, soft-touch threads like "Microfiber Thread" or "Bulky Nylon." These super-soft, flexible threads dramatically improve the next-to-skin feel of every single seam.

This is a detail that most brands overlook, but it makes a world of difference. Standard spun polyester thread is strong and cheap, but its fibrous texture can feel like fine-grit sandpaper against sensitive skin. When we produce high-end lingerie, we use a different class of thread. Microfiber threads are made from the same ultra-fine filaments as premium fabrics, making them incredibly soft. Bulky nylon thread is even more luxurious; it's a fluffy, voluminous thread that spreads out when sewn, creating a soft, cushion-like seam. Yes, these threads are more expensive, but the improvement in comfort is exponential. It's an invisible detail that your customers will feel, even if they don't know why.

Tech #3: Are Your Elastics Leaving a Mark?

A customer takes off her bra at the end of the day and sees angry red marks along her ribcage and shoulders. The elastic provides support, but at the cost of all-day comfort.

The boundaries of your garment—the waistbands, leg openings, and straps—are the most common sources of discomfort. The solution is to "soften the edges" using techniques like "Plush-Back Elastics" or "Enclosed Elastics," ensuring every point of contact with the skin is cushioned and gentle.

An exposed, raw elastic edge is simply not acceptable for a premium, comfort-focused brand. As part of our comprehensive OEM/ODM services, we have a whole library of soft-edge solutions we present to our clients.

- Plush-Back (or Brushed-Back) Elastics: This is the most common and effective solution. The side of the elastic that touches the skin is woven or brushed to have a super-soft, plush, almost fuzzy texture. It feels amazing and prevents chafing.

- Enclosed Elastics: For the ultimate soft edge, the entire elastic is encased within a folded-over layer of the main garment fabric. This means the only thing touching the skin is the soft main fabric itself. It's a more labor-intensive process but offers an incredibly clean look and luxurious feel.

- Bonded Edges: This technique eliminates elastics and sewing altogether at the leg or waist, using a special adhesive to create a super-flat, seamless edge that is completely invisible and irritation-free.

Tech #4: Is Your Label the Most Annoying Part of Your Lingerie?

What's the first thing many women do when they buy a new bra or pair of underwear? They cut out the scratchy, annoying care label. This is a design failure.

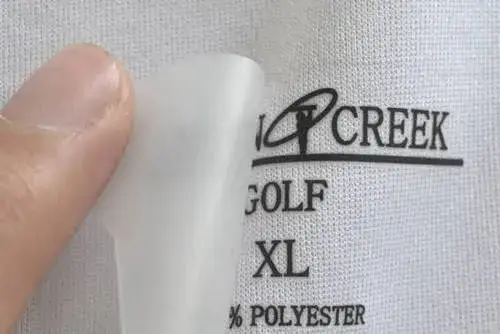

The traditional sewn-in label is an outdated source of constant irritation. The modern standard for high-quality, comfortable lingerie is "Tagless Labeling." Using technologies like heat transfer or pad printing, all the required information is printed directly onto the fabric, creating a truly "no-feel" label.

This should be a non-negotiable for any brand that claims to prioritize comfort. A sewn-in label, with its sharp corners and abrasive texture, is a persistent annoyance. We've invested in the technology to offer tagless solutions to all our clients.

- Heat Transfer: This is the most popular method. The label information is printed onto a special transfer paper and then applied to the garment with heat and pressure. The result is a smooth, flexible label that is soft to the touch.

- Pad Printing: This method uses a soft silicone pad to transfer ink directly onto the fabric, similar to stamping. It's excellent for more delicate or textured fabrics where a heat transfer might not apply as well.

Adopting a tagless label is one of the easiest and most impactful ways to instantly upgrade the comfort and perceived quality of your product.

Conclusion

The soul of a cut-and-sew garment lies in its details. By obsessing over these four key elements—the seams, the thread, the edges, and the labels—you can engineer a product that offers the design beauty of cut-and-sew with the modern comfort your customer demands.

Frequently Asked Questions (FAQ)

1. Is a flatlock seam as strong as an overlock seam?

Yes. When done correctly with high-quality thread, a flatlock seam is incredibly strong and durable. It is the standard construction method for high-performance activewear, which endures enormous stress, proving its strength and reliability.

2. Does using premium thread really increase the cost that much?

While premium threads are more expensive per spool, the actual amount of thread in a single garment is quite small. The impact on the final unit cost is usually just a few cents. However, the impact on comfort and perceived quality is immense, making it one of the most cost-effective upgrades you can make.

3. What is the difference between "cut-and-sew" and "seamless" manufacturing?

Cut-and-sew is the traditional method where patterns are cut from flat pieces of fabric and then sewn together. Seamless manufacturing uses large, circular knitting machines to knit a garment into a tube shape in one continuous process, eliminating most or all seams. Seamless is great for comfort but offers less design flexibility than cut-and-sew.

4. Can you use bonded edges on any fabric?

No. Bonding technology (using a special adhesive film and heat/pressure) works best on synthetic fabrics like nylon/spandex or polyester/spandex blends. It does not work well on natural fibers like 100% cotton, as the adhesive needs a smooth, stable synthetic surface to create a strong, permanent bond.