Top 4 Methods for Finding a Reliable Lingerie Manufacturer in Bangladesh?

You're hearing the buzz about Bangladesh as a global manufacturing powerhouse, especially for high-volume basics. As you consider diversifying your supply chain beyond China, you're faced with a wall of uncertainty: Where do you even start looking? How do you find a factory you can trust?

To successfully source from Bangladesh, you need a multi-channel approach. The top four methods are: using online B2B platforms for initial screening, leveraging professional networks and industry associations like the BGMEA for deeper insights, attending local trade shows for direct contact, and implementing a rigorous supplier vetting process to ensure quality and compliance.

As a manufacturer based in China, I understand the appeal of supply chain diversification. Many of our clients at HAVING (China) Ltd. partner with us for their complex, high-tech, or fast-turnaround collections, while exploring countries like Bangladesh for their large-volume, basic cotton programs. It's a smart strategy. But navigating a new sourcing destination requires a clear map. Having spent decades in the global apparel industry, I want to share the professional methods we advise our own partners to use when they explore new territories. This is your guide to finding a great partner in Bangladesh.

Method #1: Are You Using Online Platforms for Smart Screening?

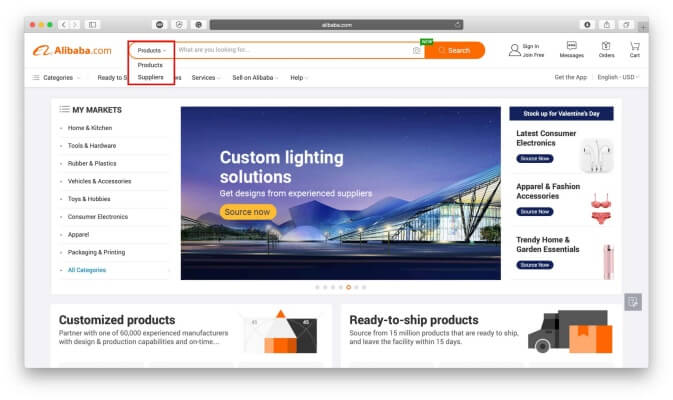

Your first instinct might be to search on massive B2B platforms like Alibaba or Global Sources. This is a good starting point for casting a wide net, but it's also filled with pitfalls if you don't know how to navigate it.

Online platforms are excellent tools for initial discovery and creating a long list of potential suppliers. The key is to use their filters effectively and develop a keen eye for distinguishing between actual factories and pure trading companies. Look for detailed production information and verified credentials.

The sheer number of listings can be overwhelming. The biggest challenge is identifying the true source. A trading company might have a slick website but no actual machines. One trick I recommend is to look closely at the product photos. Does the supplier show a wide variety of unrelated products (e.g., t-shirts, hardware, and lingerie)? That's often a sign of a trading company. A specialized factory will have a deep, focused portfolio. Also, look for mentions of specific machinery or technical capabilities. While we in China might highlight our advanced seamless knitting or bonding technology for shapewear, a strong Bangladesh factory might emphasize its large-scale knitting capacity for cotton basics. Use these platforms for what they are—a discovery tool—before moving on to deeper verification.

How to Filter the Noise Online

- Use Specific Keywords: Instead of "lingerie factory," try "knit cotton panty manufacturer Dhaka" or "BSCI certified bra factory Bangladesh."

- Check Business Type: Look for suppliers listed as "Manufacturer." Be skeptical of those who are only "Trading Company" or "Distributor."

- Analyze the Product Range: A focused product range (e.g., only knit underwear) is a good sign.

- Ask for a Business License & Certifications: A real factory will have no problem providing these documents.

Method #2: Are You Tapping into Professional Networks?

Online platforms will only get you so far. The best partners are often found through trusted industry connections and official channels. This requires a more proactive, investigative approach.

To find vetted, high-quality suppliers, you must dig deeper. Use professional networks like LinkedIn to connect with sourcing agents and production managers in Bangladesh, and leverage the official member directory of the Bangladesh Garment Manufacturers and Exporters Association (BGMEA).

This is an insider's technique. The BGMEA is the most powerful industry body in the country. Their member directory is a goldmine of legitimate, export-focused factories. Contacting factories through this official channel already puts you on a more professional footing. On LinkedIn, you can search for "Lingerie Production Manager Dhaka" and connect with professionals on the ground. Ask them for recommendations or insights. When our clients ask us for advice on diversifying, we always tell them to build these human connections. While our own OEM/ODM services in China offer an integrated, high-tech solution, we know that success in any country is built on trust, and trust comes from these professional networks.

Your Deep Dive Toolkit

| Channel | Actionable Step | Why It Works |

|---|---|---|

| **BGMEA Directory** | Go to the official BGMEA website, find the member list, and filter by product category (e.g., knitwear, intimate apparel). | These are established, export-oriented factories that are part of the official industry body. A much higher level of trust. |

| **LinkedIn** | Connect with sourcing managers, quality controllers, and merchandisers based in Dhaka. Build relationships and ask for insights. | Provides on-the-ground intelligence and personal recommendations that you can't find on a B2B platform. |

| **Sourcing Agents** | Hire a reputable, local sourcing agent. They have a pre-vetted list of factories and can manage the process for you. | Good for brands without the time or experience to manage the process themselves, but it adds a cost layer. |

Method #3: Are You Making the Trip?

You can do a lot of research from your desk. But nothing replaces seeing the operation with your own eyes and holding the product in your own hands.

Attending a major apparel trade show in or near Bangladesh, like the Dhaka Int'l Textile & Garment Machinery Exhibition (DTG), is the single most effective way to meet a large number of potential partners in a short time. Face-to-face meetings are the ultimate way to assess a factory's professionalism and product quality.

There's a different energy when you meet someone in person. You can instantly gauge their passion and professionalism. You can touch and feel the quality of the men's underwear or women's bras they are producing. We exhibit at major global shows for this very reason—it’s the best way to build trust. I always advise clients to plan a trip. Spend a few days at a trade show in Dhaka, and then use the following week to visit the top 2-3 factories you met. This investment of time and money at the beginning of the relationship is the best insurance you can buy against future production problems.

The Final Checkpoint: Is Your Potential Partner Truly Vetted?

You've used these methods to create a shortlist of 3-5 promising factories. Now comes the most critical step of all: the formal vetting process. Do not skip a single step here.

No matter how you find a supplier, you must put them through a rigorous, multi-stage vetting process. This involves requesting a detailed quotation (RFQ), evaluating their samples against your standards, verifying their social and chemical compliance certificates, and ideally, conducting a factory audit.

This is where you move from conversation to confirmation. This is the standard we hold all our own material suppliers to, and it's the standard you should use too.

- Request for Quotation (RFQ): Send your detailed tech pack and ask for an itemized price quote. How professionally and quickly they respond is your first test.

- Sample Evaluation: Pay for samples. There is no substitute. Check the quality, the stitching, the fit, and the feel. Does it meet your brand's standards?

- Certificate Verification: Ask for their social compliance audit (like BSCI or WRAP) and their chemical safety certificates (like OEKO-TEX®). Don't just take the PDF; verify the certificate number on the official databases.

- Factory Audit: For a significant partnership, a factory audit (either done by you or a third-party service) is essential. This verifies their capacity, equipment, and working conditions.

Conclusion

Finding the right manufacturing partner in Bangladesh is a process of strategic, multi-layered research. It's about moving beyond a simple price quote to find a partner who aligns with your quality standards, ethical values, and long-term vision—the same principles that build any successful partnership, anywhere in the world.

Frequently Asked Questions (FAQ)

1. What is Bangladesh best known for manufacturing?

Bangladesh is a global leader in high-volume production of knitwear (like t-shirts and polo shirts) and cotton-based products, including basic underwear and denim. While its capabilities in more complex lingerie are growing, its primary strength lies in large orders of less complex items.

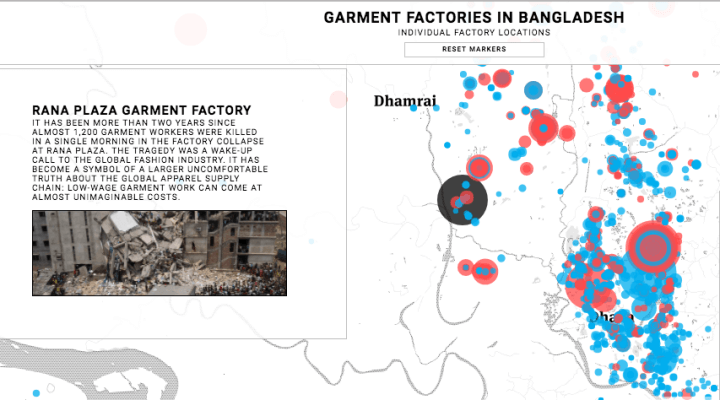

2. What are the main manufacturing hubs in Bangladesh?

The two main hubs for the garment industry are the capital city, Dhaka, and the port city of Chittagong. Many of the largest and most advanced factories are located in and around these two cities.

3. What is the BGMEA?

The BGMEA stands for the Bangladesh Garment Manufacturers and Exporters Association. It is the primary trade body for the country's massive ready-made garment (RMG) industry, representing the vast majority of factories.

4. Are there any specific challenges to be aware of when sourcing from Bangladesh?

While a powerful sourcing destination, potential challenges can include longer lead times compared to China due to less developed internal logistics and reliance on imported raw materials for more complex fabrics. Political stability and infrastructure development can also be factors to monitor. Diligent planning and clear communication are key.