Top 5 Factors That Determine Your Lingerie's True Cost: A Manufacturer's Breakdown?

You've just received two quotes for what seems like the same bra. One is $5, the other is $7.50. Frustrated, you ask the inevitable question: "Why is your price so much higher?" This confusion can lead to poor decisions that damage your budget and your brand.

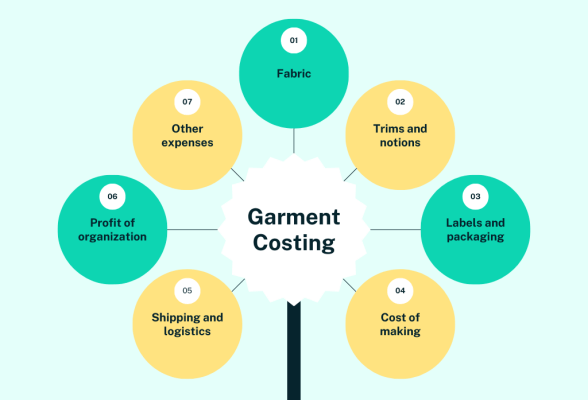

The price of a piece of lingerie is determined by five key factors: the quality and quantity of the main fabric, the cost of all trims and hardware, the complexity of the labor (CMT), hidden overheads and profit, and the overall design complexity which impacts all of the above. Understanding these is the key to truly evaluating a price quote.

"Why is my quote higher?" It’s the most common question I hear from new brand founders. And it’s a fair one. The answer lies in the details. A price quote isn't just a number; it's a story about the quality, complexity, and craftsmanship of the product you want to create. As a manufacturer, a transparent partner should be able to walk you through that story. At HAVING (China) Ltd., we believe an educated client is the best client. This guide will break down the 5 key factors that make up the true cost of your lingerie, so you can stop comparing apples to oranges and start making truly informed decisions.

Factor #1: Is Your Fabric Just Fabric, or an Investment?

This is the biggest piece of the pie, typically making up 40-60% of your garment's cost. You've chosen a lace fabric, but why does one factory quote it so much higher than another?

The cost of your main fabric is driven by its composition (e.g., standard vs. premium lace), its weight, and crucially, the amount of waste generated during cutting. Intricate designs requiring "pattern matching" can dramatically increase fabric consumption and cost, a detail often overlooked by new brands.

Let me tell you a quick story. A client wanted to produce a beautiful lace bralette. They received a very low quote from another factory and couldn't understand why ours was higher. The secret was in the cutting. Their design required the scallop edge of the lace to be perfectly symmetrical on both cups. This is called "pattern matching." To achieve this, our cutters have to carefully place the pattern pieces, leaving large, unusable gaps in the fabric. This process can increase fabric waste from a standard 15% to over 40%. The cheaper factory was not accounting for this; they were planning to cut the pieces randomly, which would have resulted in a cheap-looking, asymmetrical product. The fabric itself is only part of the cost; how you use it is just as important.

The Material Cost Breakdown

- Main Fabric: A basic nylon lace might cost $3/yard, while a high-quality certified jacquard lace could be $10/yard. For a single bra, this difference alone can change the price by several dollars.

- Lining Fabric: The fabric that touches the skin, like cotton or mesh, also has different quality and cost tiers.

- Fabric Waste: As mentioned, this is a huge hidden factor. A simple T-shirt bra has low waste. A complex lace bodysuit has very high waste.

Factor #2: Are You Accounting for Every Tiny Piece?

A bra isn't just fabric. It's a complex assembly of many small components, often called "trims" or "findings." Are you considering the cost of every strap, slider, and hook?

Trims and accessories are a significant cost component. This includes all elastics (for the band and straps), the hook-and-eye closure, rings and sliders for adjustment, and any decorative hardware. The quality and origin of these small pieces can substantially impact the final price and performance.

This is another area where costs can hide in plain sight. A brand might specify a "gold slider" in their tech pack. But is that a cheap plastic slider painted gold, or a high-quality, zinc alloy slider with real gold plating that won't chip or cause skin irritation? The cost difference is huge. The same goes for elastics. A basic elastic might lose its stretch after ten washes, leading to poor reviews. A high-quality elastic with a soft backing will perform for years. As part of our OEM/ODM services, we provide a detailed Bill of Materials (BOM) that specifies the supplier and cost for every single component, so you know exactly what you're paying for.

Factor #3: How Much "Work" Is in Your Work of Art?

This is the labor cost, often referred to as CMT (Cut, Make, Trim). It typically accounts for 20-30% of the price. Why can the labor cost for two different bras vary so much?

CMT is not a fixed cost; it's a direct function of time. A simple seamless panty might take a sewer 5 minutes to make, while a complex, multi-part underwire bra could take 45 minutes. The more seams, panels, and special techniques your design has, the higher the labor cost will be.

The complexity of the design is the biggest driver of labor costs. A T-shirt bra might have 15-20 operational steps. A complex corset or a piece of ornate bridal lingerie could have over 50 steps, involving different specialized sewing machines and highly skilled workers. Modern techniques like bonding or "stitch-free" seams also require expensive machinery and specially trained operators, which adds to the cost. When you design a product, you are also designing a production process. Our role as your partner is to provide feedback on your design—a process called "Design for Manufacturability"—to help you achieve your aesthetic vision at the most efficient possible cost.

Factor #4: What Are the "Invisible" Factory Costs?

Beyond the physical materials and labor, there are other essential costs that are part of running a professional, ethical, and high-quality manufacturing operation. These often account for 10-15% of the total.

Every price quote includes a portion for "hidden" overheads and profit. This covers the costs of sampling and development, quality control staff, administration, factory compliance audits (for ethical production), and a reasonable profit margin that allows the factory to reinvest and grow.

This is the part that brands often don't see but is crucial for a reliable partnership. A factory that offers a suspiciously low price is likely cutting corners in these areas. They might have no real QC team, or they might operate with poor ethical standards. The price from a reputable factory includes the cost of being a good business: paying fair wages, maintaining a safe and clean facility, and investing in quality systems. Our profit margin allows us to reinvest in new technologies and training for our team. When you pay for these "invisible" costs, you're not just buying a product; you're buying peace of mind, reliability, and an ethical supply chain.

The Final Breakdown: A Tale of Two Bras

Let's see how these factors play out in a real-world comparison. Here is a simplified, hypothetical cost breakdown for a basic T-shirt bra versus a complex lace bralette.

| Cost Component | Basic T-Shirt Bra (Example) | Complex Lace Bralette (Example) | Reason for Difference |

|---|---|---|---|

| **1. Fabric & Lining** | $1.50 | $3.00 | Premium lace is more expensive; pattern matching increases waste. |

| **2. Trims (Elastic, Hardware)** | $0.75 | $1.25 | Decorative elastics and higher quality, coated metal hardware. |

| **3. CMT (Labor)** | $1.25 | $2.00 | More complex construction and sewing with delicate lace takes more time. |

| **4. Overheads & Profit** | $0.75 | $1.15 | Calculated as a percentage of the higher sub-total cost. |

| **Total FOB Price** | $4.25 | $7.40 | Nearly 75% more expensive due to design choices. |

Conclusion

The cheapest price is rarely the best value. By understanding these five key cost drivers, you can have more productive conversations with your manufacturing partners and make strategic decisions that balance your design vision with your financial goals.

Frequently Asked Questions (FAQ)

1. What does FOB mean in a price quote?

FOB stands for "Free On Board." The FOB price is the total cost to produce your garment and deliver it to the port of departure in the country of origin (e.g., FOB Shanghai). It does NOT include the cost of ocean shipping, insurance, import duties, or local delivery in your country.

2. How can I lower my production costs?

The easiest ways to lower costs are to simplify your design (fewer seams and pieces), choose more cost-effective materials, and increase your order quantity (MOQ). A good manufacturer can also offer "value engineering" suggestions, like slightly changing a seam type to make it faster to sew without sacrificing quality.

3. Does the color of the garment affect the price?

Sometimes, yes. Standard colors like black, white, and nude are often readily available from fabric mills with lower minimums. If you require a custom color that needs to be specifically dyed for your brand (a "lab dip"), you will likely face a higher MOQ for the fabric, which can increase the overall cost if you have to order more than you need.

4. Why do larger sizes sometimes cost more?

Larger sizes (especially in plus-size ranges) can sometimes have a small surcharge. This is because they require more fabric to produce. For complex bras, they may also require more supportive components, like wider straps or a 4-hook back, which adds to the material cost.