8 Questions You MUST Ask a Lingerie Manufacturer Before Signing a Contract?

You've found a manufacturer who has given you a great price, and you're ready to sign the contract and start production. But a feeling of uncertainty is holding you back—what if you've missed something critical? What questions should you have asked?

Signing a manufacturing contract without a thorough vetting process is a blind risk. Before you commit, you MUST ask about their business type (factory vs. trader), their experience with your specific product, their MOQ and pricing structure, their quality control process, lead times, payment terms, IP protection, and their communication methods.

A manufacturing agreement isn't just a piece of paper; it's the foundation of a partnership that can make or break your brand. I've seen founders get so excited about a low price that they skip these crucial questions, only to find themselves locked in a contract with a partner who can't meet their quality standards or deadlines. As a manufacturer, I believe a good partner is one who can answer these questions confidently and transparently. At HAVING (China) Ltd., we welcome these conversations because they build the trust needed for a successful, long-term relationship. This is your final checklist. Do not sign anything until you have satisfactory answers to all eight of these questions.

Question #1: Are You a Factory or a Trading Company?

The company you're speaking with has a professional website and a sales rep who speaks perfect English. But who are they really? Are they the ones who will actually be making your product, or are they a middleman?

This is the most fundamental question you must ask. A factory directly manufactures your goods, offering more control and better pricing. A trading company outsources your order to other factories, which can add cost, communication layers, and a significant loss of quality control. You need to know exactly who you are working with.

There is nothing inherently wrong with trading companies, but you need to make an informed choice. I have seen situations where a brand thought they were working with a high-end factory, but it was actually a trading company that placed their order in a low-cost, low-quality workshop to maximize their own profit margin. The brand had no idea where their product was being made and no power to fix problems when they arose. When you work directly with a manufacturer like us, you are speaking to the source. You can see our facility (even virtually), you know who is handling your product, and there are no hidden markups. Always ask for their business license; it will state their official business scope as either a "manufacturer" or "trading company."

Why This Distinction Is Critical

| Factor | Direct Factory (like HAVING) | Trading Company |

|---|---|---|

| **Price** | Lower (no middleman markup) | Higher (includes their profit margin) |

| **Control** | High (direct influence over production) | Low (you have no control over which factory they choose) |

| **Communication** | Direct and faster | Indirect and slower (messages are relayed) |

| **Transparency** | High (you know where your product is made) | Low (they may not disclose the actual factory) |

Question #2: Can You Show Me Examples of Similar Products You Have Made?

Their website looks great, but do they have real, hands-on experience making the specific type of lingerie you need? Making a simple bralette is completely different from making a complex underwire bra or high-compression shapewear.

You must verify their technical expertise. Ask to see physical samples or detailed photos of products they have manufactured that are similar to yours in terms of complexity, fabric, and construction. This is the only way to gauge their true capabilities.

"Yes, we can make that" is an easy thing to say. Proving it is another matter. A brand once approached us to produce a complex piece of shapewear after their previous partner, who specialized in simple t-shirts, completely failed. The seams were puckered, and the compression was all wrong. They chose them because they were cheap, not because they had the right experience. When a potential client asks us this question, we are excited to answer. We can show them examples of bonded seams, zoned compression garments, and delicate lace application. A confident, experienced manufacturer will have a portfolio of work they are proud to share. If they are hesitant or can only show you images from a catalog, that's a major red flag.

Question #3: What is Your MOQ, Pricing Structure, and What's Included?

You've received a per-unit price, but what does it really include? And can you meet their minimums? The financial details need to be crystal clear before you commit.

You must get a detailed breakdown of their Minimum Order Quantity (MOQ) per style/color and a clear confirmation of what the quoted price includes. Ask specifically about costs for samples, grading, packaging, and lab dips to avoid unexpected charges later.

We covered this in our article on hidden costs, but it's so important it must be on this final checklist. The number one cause of disputes between brands and manufacturers is money. A low "teaser" price is useless if you are then charged for every single development step. Before signing, you need a written confirmation of the full cost structure. What is the cost for the first prototype? For a full-size set of samples? Do they charge for color matching (lab dips)? Is basic packaging included? A professional partner will provide a clear, itemized quote. They will also be upfront about their MOQs and work with you to find a solution, rather than surprising you with an impossible minimum after you've already invested time and money in sampling.

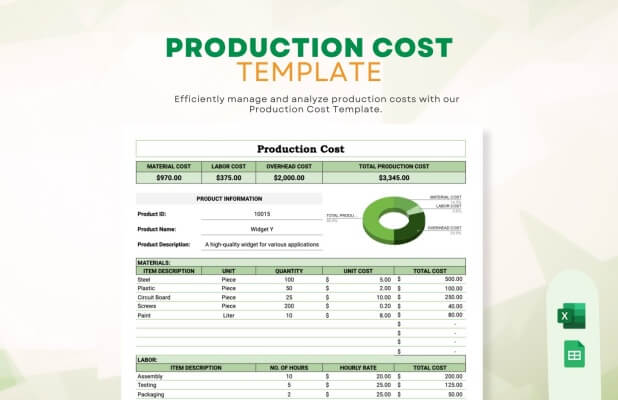

Question #4: What is Your Quality Control Process?

How will you ensure that the 1,000th piece looks just as good as the approved "golden sample"? Hoping for the best is not a strategy.

You must understand the factory's internal Quality Control (QC) process from start to finish. Ask about their checkpoints: do they inspect raw materials (IQC), monitor during production (IPQC/DUPRO), and perform a final inspection (FQC)? A factory without a documented QC process is a recipe for disaster.

Quality isn't something you check for at the end; it's something you build in at every stage. A good factory doesn't just rely on a final inspection. They have systems in place throughout the production line. For example, our QC team checks the fabric when it arrives from the mill to ensure there are no defects before we cut it. We have line leaders who monitor the sewing quality in real-time. Finally, we have a dedicated final inspection team that checks the finished goods based on AQL standards. We welcome third-party inspectors because we are confident in our process. You should ask a potential partner to explain their QC system. If they just say, "Don't worry, we check everything," without providing specifics, they don't have a real system.

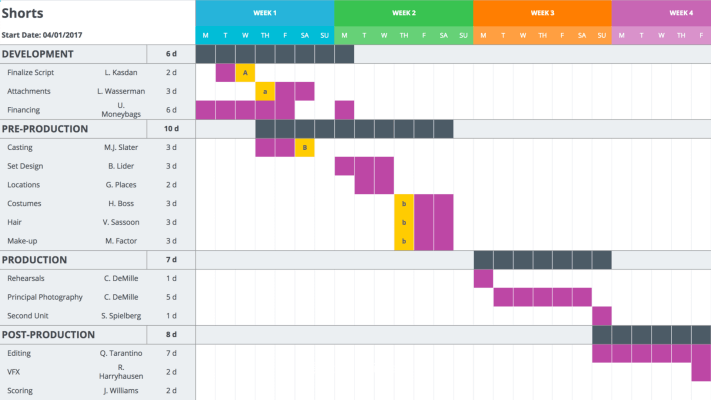

Question #5: What Are Your Production Lead Times?

Knowing your production timeline is critical for planning your marketing, launch dates, and cash flow. A vague answer is not acceptable.

You must get a clear, written estimate of the production lead time that starts from the date you approve the pre-production sample (PPS) and place your bulk order. Also, ask how this lead time might be affected by peak seasons or holidays like Chinese New Year.

A common mistake for new brands is miscalculating their timeline. The "lead time" does not start when you first contact the factory. It starts after the entire development and sampling process is complete and you have officially signed off on the final sample. A typical lead time for a lingerie order is 45-90 days. It's crucial to get this in writing. You also need to be aware of production black-out periods. The entire country shuts down for Chinese New Year (usually in Jan/Feb) for several weeks. A professional factory will proactively advise you to place orders well before this holiday to avoid significant delays.

Question #6: What Are Your Payment Terms?

How and when you are expected to pay is a critical part of your financial planning. You need to ensure the terms are fair and standard for the industry.

You must have the payment terms clearly stated in your contract. The industry standard for a new client is a 30-50% deposit to begin production and the remaining 50-70% balance due upon completion, before the goods are shipped. Be very wary of any supplier demanding 100% upfront.

The deposit shows you are a serious buyer and allows the factory to purchase the raw materials for your order. The final balance payment is made after you have had a chance to perform your final quality inspection and are satisfied with the goods. This structure protects both parties. A demand for 100% payment upfront from a new supplier is a massive red flag and often associated with scams. A legitimate, established business like ours operates on standard industry terms because we are confident in our ability to deliver a quality product that you will be happy to pay the balance for upon completion.

Question #7: How Do You Protect My Intellectual Property (IP)?

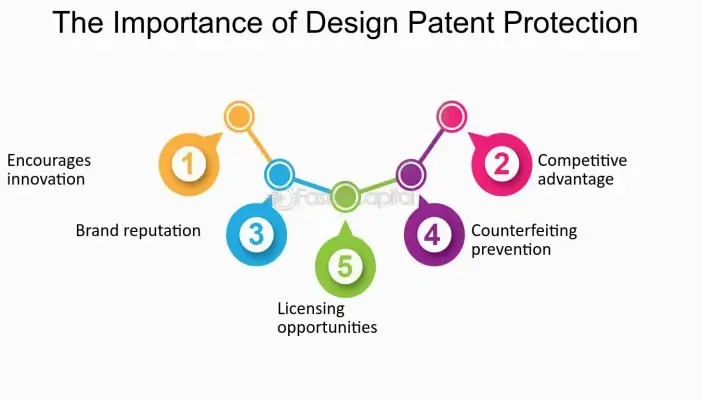

Your designs are your brand's most valuable asset. You need to be sure your manufacturing partner will protect them.

You must ask what specific measures the factory takes to protect your intellectual property. A trustworthy partner will be willing to sign a well-drafted NNN (Non-Disclosure, Non-Use, Non-Circumvention) agreement and will be able to explain their internal policies for protecting client designs.

As we've discussed before, a reputable factory's entire business is built on trust. It is not in our interest to copy designs. However, you should still be proactive. The best legal tool is an NNN agreement that is specifically designed for China and is written in Chinese. Beyond legal documents, ask about their practical measures. How do they handle samples from competing brands? Is access to the sample room restricted? Who on their team will have access to your designs? A professional manufacturer will understand and respect your concerns and will be able to answer these questions reassuringly. Their willingness to have this conversation is a good sign in itself.

Question #8: Who Will Be My Main Point of Contact?

When you have a question or need to make a change, who do you call? Knowing how communication will be handled is key to a smooth and stress-free partnership.

You must clarify who your dedicated account manager or merchandiser will be and what their preferred communication methods and response times are. A single, reliable point of contact who understands your brand is essential for effective day-to-day operations.

There's nothing more frustrating than having your emails go unanswered or being passed around to different people who don't know your project's history. This is why our clients are assigned a dedicated English-speaking merchandiser from day one. This person is your advocate inside the factory. They manage your project from sampling to shipment, answer your questions, and provide you with regular updates. Before signing a contract, you should know who this person is. You should feel confident in their ability to communicate clearly and manage your project effectively. This relationship will be the bedrock of your manufacturing partnership.

Conclusion

Asking these eight questions transforms you from a hopeful buyer into an empowered business partner. It sets a professional tone and ensures you are entering a partnership that is built on clarity, trust, and mutual respect.

Frequently Asked Questions (FAQ)

1. What is an NNN agreement and how is it different from an NDA?

An NDA (Non-Disclosure Agreement) is a Western legal concept that primarily prevents public disclosure. An NNN agreement, designed for China, is more robust. It covers Non-Disclosure, Non-Use (they can't use your idea for themselves), and Non-Circumvention (they can't go around you to your customers or suppliers). It must be in Chinese and governed by Chinese law to be effective.

2. What does AQL stand for in Quality Control?

AQL stands for Acceptable Quality Limit. It is a statistical method used to determine the sample size for inspection and the maximum number of defects allowed for that sample size. It's the industry standard for ensuring a shipment meets quality requirements without having to inspect every single item.

3. Is it normal for a factory to charge for samples?

Yes, it is completely normal for factories to charge for samples, especially for a new client. The sampling process requires significant time from skilled pattern makers and sample room sewers. Often, factories will offer to credit the sample fee back to you if you proceed with a bulk production order.

4. What should be included in a manufacturing contract?

A good manufacturing contract should include: detailed product specifications (referencing the tech pack), the agreed price per unit, the total order quantity, the payment terms, the production lead time, the quality standards (AQL), shipping terms (FOB), and clauses on IP protection and dispute resolution.