Why Most Shapewear Fails: 3 Technical Secrets to Creating a Product That Actually Works?

Your customers buy shapewear hoping for a magical transformation, only to be disappointed by a garment that rolls down, feels suffocating, or creates unnatural bulges. This failure isn't bad luck; it's bad design.

Most shapewear fails due to three technical flaws: uniform compression that creates a "sausage effect," poor construction that causes rolling and digging, and using non-breathable fabrics. Truly effective shapewear requires zoned compression, intelligent seam work, and high-performance, breathable materials.

The global shapewear market is booming, but it's filled with products that over-promise and under-deliver. As a manufacturer, I've seen hundreds of designs, and the difference between a best-seller and a failure almost always comes down to a few key technical details. Brands that understand these secrets are the ones that earn rave reviews and loyal customers. Our "body-before-fabric" philosophy at HAVING (China) Ltd. is perfectly suited for high-performance garments like shapewear, because true shaping is about working with the body, not just squeezing it.

Secret #1: Are You Flattening Everything Instead of Shaping?

The most common complaint about shapewear is the dreaded "sausage effect." The garment squeezes indiscriminately, flattening curves you want to keep (like the bust or butt) and creating uncomfortable pressure everywhere else, making the wearer look like a tube.

This happens because the garment uses uniform compression, applying the same level of force across the entire torso. Great shapewear uses "zoned compression," a sophisticated technique that applies firm control only where it's needed (like the tummy) and gentle, flexible support everywhere else.

Creating zoned compression is where true manufacturing expertise comes into play. It’s not something just any factory can do. A few years ago, a promising startup came to us with a shapewear bodysuit they had sampled elsewhere. The prototype was basically a tight tube of power mesh. It was uncomfortable, and frankly, it made their fit model look worse. They were frustrated. We explained the concept of zoned compression and re-engineered the garment. By weaving a high-compression panel specifically for the abdomen and using a more flexible, breathable knit around the bust and hips, we created a garment that sculpted the waist while enhancing the body's natural curves. This is the secret. It’s about being an architect for the body, not just a builder of a tight garment.

The Art of Intelligent Shaping

Zoned compression is achieved through advanced knitting technology and smart material placement.

- Seamless Knitting Technology: The most advanced method uses sophisticated circular knitting machines that can change the knit structure and tension in different areas of the same continuous piece of fabric. This creates a seamless garment with built-in zones of control.

- Variable Fabric Panels: A more traditional, but still effective, method involves sewing together different panels of fabric with varying levels of power and stretch. For example, a non-stretch satin panel might be used for the front tummy area, while a high-stretch power mesh is used for the back and hips.

- Bonded Support Slings: This technique involves bonding or laminating extra layers of fabric or supportive material onto the inside of the garment in specific zones, like under the bust or along the sides of the waist, to provide targeted lift and control.

| Compression Type | How It Works | Result |

|---|---|---|

| **Uniform Compression (Fails)** | Applies the same high pressure everywhere. | Uncomfortable "sausage effect," flattens natural curves. |

| **Zoned Compression (Works)** | Applies firm, medium, and light pressure to different body zones. | Sculpts, smooths, and enhances curves comfortably and naturally. |

Secret #2: Is Your Garment at War With Itself?

The second biggest failure is a garment that won't stay put. The waistband rolls down, the leg openings dig into the thigh, and the straps leave painful red marks. The customer spends all day adjusting it, feeling more frustrated than fabulous.

Shapewear fails to stay in place because of poor "anchoring" and construction. An effective design requires intelligent features like silicone grippers, bonded "no-roll" waistbands, and carefully placed seams that work with the body's movement, not against it.

![]()

This is all about physics and engineering. When you create a high-compression garment, that force has to be managed at the edges. A simple folded and sewn hem at the waist is a guaranteed recipe for rolling. The tension of the fabric will always try to return to its smallest point, which means it will roll down your torso. As a leading manufacturer of high-performance shapewear and bodysuits, we've spent years perfecting these finishing techniques. We use wide, seamless waistbands with bonded internal structures or precisely applied silicone strips that gently adhere to the skin. It’s a small detail that makes a world of difference in the wearer's experience. It’s the secret to a garment that feels like a second skin, not a cage.

Engineering a Secure and Comfortable Fit

A garment that stays put is a feat of clever engineering.

- Silicone Grippers: These are thin, often wavy lines of clear silicone applied to the inside hem of waistbands, leg openings, or strapless bust lines. They provide gentle grip against the skin without irritation.

- Bonded & Seamless Edges: Instead of a thick, sewn hem, modern shapewear uses bonding or laser-cutting technology to create flat, seamless edges that transition smoothly onto the skin. This prevents the "digging in" effect at the leg or waist.

- Strategic Seaming & Support Structures: Seams aren't just for holding fabric together. In high-quality shapewear, they act like the support beams of a building. For example, vertical seams at the side can help prevent the garment from bunching at the waist, while flexible boning can provide extra postural support and prevent the dreaded roll-down.

Secret #3: Are Your Customers Wearing a Plastic Bag?

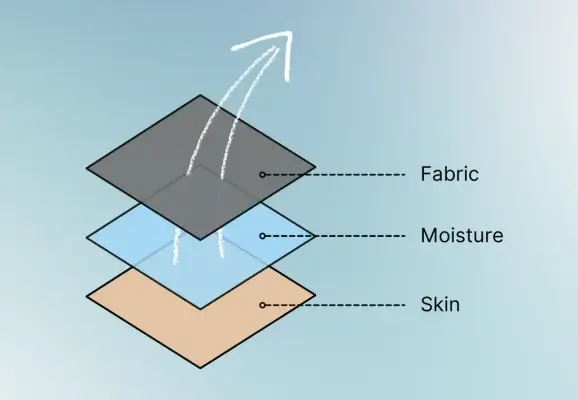

Your shapewear might offer amazing compression, but if it traps heat and moisture, no one will wear it for more than an hour. Customers complain of feeling hot, sweaty, and suffocated, a sign that the fabric is not functional.

Breathability is a non-negotiable for shapewear. The secret is using high-tech synthetic blends, typically of Nylon and Spandex (Lycra), that are specifically engineered for moisture-wicking and airflow. Heavy, cheap fabrics with low nylon content will trap heat and lead to discomfort.

Many brands make the mistake of choosing a fabric based only on its power or compression level. But the composition of that fabric is what determines its comfort. I've seen brands try to use heavy polyester blends to save money, and the customer feedback is always disastrous. A high percentage of Nylon is crucial because its fiber structure is excellent at pulling moisture away from the skin and allowing it to evaporate. Combining this with a high-quality Spandex (like Lycra® brand fibers) ensures you get powerful stretch and recovery without sacrificing breathability. As part of our OEM/ODM services, we work with our clients to select the perfect fabric blend that balances performance with comfort, ensuring their final product is one customers will want to wear all day.

Choosing the Right High-Performance Fabric

The fabric is the engine of your shapewear. Its properties determine the final performance.

| Fabric Component | Its Role in Shapewear | What to Look For |

|---|---|---|

| **Nylon (Polyamide)** | The workhorse. Provides strength, durability, a soft hand-feel, and excellent moisture-wicking properties. | Look for a high percentage (typically 60-85%). Microfiber nylon offers an even softer, more luxurious feel. |

| **Spandex (Elastane/Lycra®)** | The engine of compression. Provides the stretch and, more importantly, the "recovery" force that shapes the body. | Look for a content between 15-40%. Higher percentage means firmer control. Branded Spandex like Lycra® often offers superior durability. |

| **Cotton or Modal (in Gusset)** | Used for the gusset (crotch area) for maximum breathability and hygiene. | A 100% cotton or modal-lined gusset is a sign of a high-quality, thoughtfully designed garment. |

Conclusion

Creating shapewear that truly works isn't magic; it's science. By mastering zoned compression, intelligent construction, and high-performance fabrics, you can create a product that customers will love, trust, and recommend.

Frequently Asked Questions (FAQ)

1. What is the difference between light, medium, and firm compression in shapewear?

Light compression offers gentle smoothing, perfect for everyday wear. Medium compression provides noticeable shaping for the tummy and waist, ideal for wearing under work or evening outfits. Firm compression offers significant sculpting and is typically reserved for special occasions or post-surgical use.

2. Why does my shapewear roll down at the waist?

Shapewear usually rolls down because the waistband lacks a proper anchor. This can be due to a narrow band, a lack of silicone grippers, or a design that doesn't have enough vertical structure (like boning or side seams) to resist the fabric's tension.

3. Is seamless shapewear better?

Seamless shapewear is generally better for comfort and invisibility under clothing, as it eliminates bulky seams that can dig in or show through. It's also the best method for creating sophisticated zoned compression, as the knit structure can be varied continuously throughout the garment.

4. Can you work out in shapewear?

While some light-compression, moisture-wicking shapewear can be comfortable during low-impact activities, it's generally not recommended for intense workouts. Proper athletic wear is designed with different seam placements and fabric properties to allow for a full range of motion and maximum breathability during exercise.