7 Costly Mistakes First-Time Lingerie Brands Make (And How to Avoid Them)?

You have a brilliant vision for a new lingerie line and a passion to make it succeed. But the path from a great idea to a profitable brand is filled with hidden traps that can drain your budget and crush your dream before you even launch.

First-time lingerie brands often make costly mistakes like creating poor tech packs, ignoring factory MOQs, underestimating production costs, neglecting fit and sizing, having a weak marketing plan, choosing the wrong manufacturing partner, and ignoring quality control. Avoiding these requires meticulous planning, clear communication, and expert guidance.

Every week, I talk to passionate entrepreneurs ready to take on the world. They have incredible design ideas, but they often don't know what they don't know about the manufacturing process. The mistakes are often the same, and they are almost always preventable. As a manufacturer who has helped launch hundreds of lines, from simple bras and panties to complex shapewear, I've seen firsthand what separates the brands that thrive from those that fail. This guide is the insider advice I wish every new founder had.

Mistake #1: Is Your "Great Idea" Just a Sketch on a Napkin?

You've sketched out a beautiful design, maybe even created a mood board. You send it to a factory expecting them to read your mind and produce a perfect sample. The factory then quotes a high price or sends back something that looks nothing like your vision.

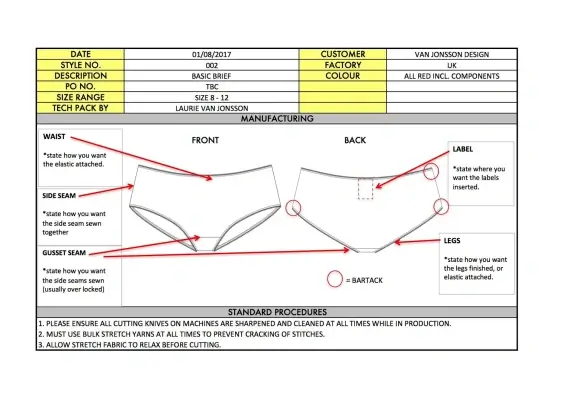

A professional, detailed "tech pack" is the single most important document in garment manufacturing. Without one, factories are forced to guess, leading to incorrect samples, endless revisions, wasted time, and soaring development costs. A simple sketch is not enough.

I cannot stress this enough: your tech pack is the blueprint for your product. A few years ago, a founder sent us a lovely drawing of a lace bralette. When we asked for the tech pack, she said, "You're the experts, can't you just make it?" We could, but the process would involve dozens of questions. What kind of lace? What's the strap width? What type of stitching? Each of these decisions affects the cost and the final look. We guide our clients through this process as part of our OEM/ODM services, but brands that arrive with a well-prepared tech pack always have a faster, smoother, and more affordable development process. It's the ultimate form of communication between your creative vision and the reality of the production floor.

What a Good Tech Pack MUST Include

Think of it as the recipe for your lingerie. If an ingredient is missing, the dish will fail.

- Flat Sketches: A clear, black-and-white technical drawing of the front, back, and side of the garment. This is different from an artistic fashion illustration.

- Bill of Materials (BOM): A complete list of every single component: main fabric, lining, lace, elastics, thread, hook-and-eye, rings, sliders, labels, etc.

- Stitching & Construction Details: Specific instructions on the type of seams (e.g., flatlock, zig-zag), stitch-per-inch (SPI), and how different parts should be joined together.

- Graded Size Chart: A table showing the precise measurements for your entire size range (S, M, L, XL, etc.), not just the sample size.

- Colorway & Placement: Details on the colors for each component and where any prints or logos should be placed.

| Without a Tech Pack | With a Good Tech Pack |

|---|---|

| Slow, expensive sample process with many errors. | Faster, more accurate samples with fewer revisions. |

| Inaccurate price quotes based on guesswork. | Precise, reliable price quotes based on facts. |

| Inconsistent quality in bulk production. | Consistent quality as a clear standard is set. |

Mistake #2: Are You Ignoring the Factory's MOQ?

You want to start small, testing the market with just 50 pieces of your new bra design in three different colors. You contact a large, professional factory and are shocked when they say their Minimum Order Quantity (MOQ) is 1,000 pieces per style, per color.

Ignoring or trying to negotiate down a factory's MOQ is a common mistake that wastes time. MOQs are not arbitrary; they are based on the minimum amount of fabric suppliers require and the production line efficiency needed to make your price point achievable.

The MOQ is often the biggest reality check for a new brand. The reason is simple: everything in the supply chain has its own minimum. Our fabric mill won't fire up its machines to dye just 50 meters of fabric for your 50 bras; their minimum might be 1000 meters. The same goes for elastics, hardware, and packaging. Trying to force a large factory to accept a tiny order is like asking a commercial bakery to bake you a single cupcake. At HAVING, we have a significant production capacity supporting over 3000 stores, so our systems are built for efficiency at scale. For brands starting out, the key is to be strategic. Instead of one style in three colors, it's often better to start with one color for three different styles (e.g., a bra, panty, and thong) to meet the fabric MOQ.

Smart Ways to Work With MOQs

Don't see the MOQ as a barrier; see it as a puzzle to be solved creatively.

- Consolidate Your Colors: Launch with one or two core colors across your entire first collection instead of a different color for each style. This allows you to meet the fabric MOQ more easily.

- Use Stock Materials: Ask your manufacturer what high-quality materials they have in stock. Using these "stock service" fabrics often comes with a much lower or even no MOQ.

- Design a Cohesive Collection: Create a small, focused collection where components can be shared. For example, the same lace or elastic can be used across a bralette, a panty, and a piece of shapewear, helping you meet the MOQ for that specific trim.

- Find the Right-Sized Partner: If your vision requires very small batches, a massive factory might not be the right fit. Seek out smaller studios or manufacturers that specialize in startup production runs. Be aware that your price per unit will be significantly higher.

Mistake #3: Is Your Budget Based on Hope?

You've calculated how much the factory will charge you per bra. You've set your retail price. The profit margin looks fantastic on paper. But have you accounted for the dozens of other expenses that stand between your factory payment and your customer's purchase?

One of the most fatal mistakes is creating a budget that only includes the per-unit manufacturing cost. A successful brand must budget for samples, shipping, import duties, marketing, packaging, website fees, and warehousing, all of which can easily double your initial investment.

Profitability is more than just the cost of goods sold. I've seen brands spend their entire starting capital on their first production run, leaving them with no money for marketing. They had a beautiful product sitting in boxes in their living room, but no way to tell the world it existed. Your production cost should ideally be no more than 25-30% of your total startup budget. The rest is needed for the essential work of building a brand and a business. A good manufacturing partner won't just give you a price; they'll help you understand the total picture, so you can plan for success.

The Iceberg of Startup Costs

The unit cost is just what you see above the water. Here's what's lurking beneath.

- Pre-Production: Sample costs, tech pack development, fit model fees.

- Production: The actual cost of the goods (FOB price).

- Logistics & Import: International shipping, insurance, import tariffs (which can be 16-20% alone), customs brokerage fees.

- Marketing & Sales: Website development, branding, photography, social media ads, PR, influencer collaborations.

- Operations: Warehousing/fulfillment center fees, packaging materials (boxes, mailers), payment processing fees, business registration, and accounting.

Failing to budget for each of these categories is setting yourself up for a cash flow crisis.

Mistake #4: Are You Forgetting Who You're Selling To?

You've designed a beautiful collection based on your own personal taste. You've used your own body as the fit model. But you haven't stopped to ask if your target customer has the same body shape or the same aesthetic preferences.

Designing in a vacuum without a clear target customer in mind is a recipe for a product no one wants to buy. Furthermore, improper fit is the number one reason for lingerie returns. You must invest in professional fitting and grading to ensure your products serve your intended audience.

Our "body-before-fabric" philosophy at HAVING is built on this principle. The garment must serve the body, not the other way around. I once saw a startup invest heavily in a line of minimalist bralettes designed for a smaller bust. The problem? Their marketing was all about body positivity and inclusivity, attracting a customer base with a much wider range of cup sizes. The result was a flood of returns and disappointed customer reviews saying, "This doesn't fit me!" It's crucial to define your target customer first, then design and fit the product specifically for them. This involves working with professional fit models who represent your target demographic and a manufacturer who understands the technical complexities of grading sizes up and down correctly.

Building for Your Customer, Not Just Yourself

- Define Your Niche: Who are you for? Is it plus-size, petite, post-mastectomy, maternity? Be specific.

- Use a Professional Fit Model: Find a model whose measurements are the exact middle of your target size range (e.g., a perfect 34B). All other sizes will be graded from this base size.

- Invest in Grading: Don't just add 2 inches to every measurement to go from a Small to a Medium. Body proportions don't scale linearly. Your manufacturer needs expertise in lingerie grading to ensure a G-cup has the right support and a petite A-cup doesn't have gaping.

- Test on Real People: Before going into bulk production, get your final samples onto as many bodies as you can within your target audience to gather feedback.

Mistake #5: Do You Have a Marketing Plan or Just a Pretty Instagram?

Your product samples look amazing, and you've set up a beautiful Instagram feed with stunning photos. You believe that once you post the pictures, customers will flock to your website.

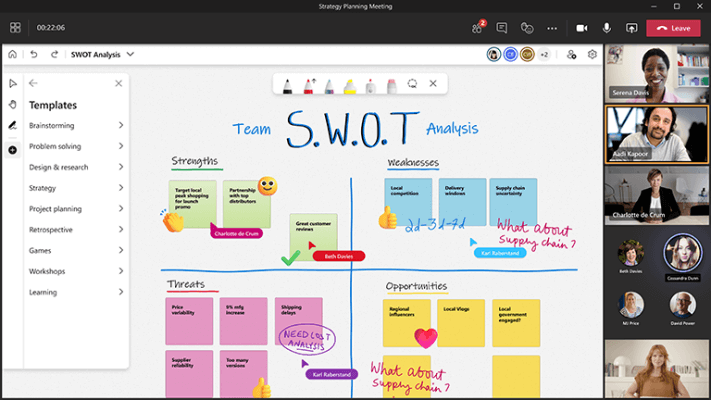

A great product does not sell itself. Believing that "if you build it, they will come" is a dangerous fantasy. Without a clear, multi-channel marketing strategy and a dedicated budget, even the most beautiful lingerie will remain an undiscovered secret.

Manufacturing is only half the battle. As a partner to over 3000 stores, we see the difference marketing makes every day. The brands that succeed are the ones that start building their community and telling their story long before the product is ready to ship. They create email lists, engage with potential customers on social media, collaborate with influencers, and plan their launch campaign meticulously. An Instagram page is a storefront, not a marketing strategy. You need a plan to bring people to that storefront. This involves understanding your customer acquisition cost (CAC), planning your email marketing flows, and telling a compelling brand story that goes beyond just pretty pictures.

Core Components of a Launch Marketing Plan

- Pre-Launch Buzz: Start collecting emails and building a social media following 3-6 months before launch. Run a "coming soon" landing page.

- Brand Storytelling: What makes you different? Is it your sustainability, your unique fit, your design philosophy? Communicate this consistently.

- Content Creation: High-quality product photography, lifestyle shots, and video content are non-negotiable.

- Launch Campaign: A coordinated push across multiple channels: email blast to your list, paid social media ads, influencer collaborations, and potential PR outreach.

- Post-Launch Engagement: The work doesn't stop after the launch. Focus on customer service, gathering reviews, and encouraging repeat purchases.

Mistake #6: Are You Choosing a Partner Based Only on Price?

You've sent your tech pack to ten different factories. You choose the one that gives you the absolute lowest price per unit, thinking you've scored a major win for your business.

Choosing a manufacturing partner based solely on the lowest bid is one of the most common and damaging mistakes. A cheap price often hides poor communication, unreliable timelines, unethical practices, and a complete lack of investment in quality. Your manufacturer is the most important partner you will have.

The relationship with your manufacturer is a long-term partnership. A good partner does more than just sew; they provide advice, solve problems, and help you improve your product. I've seen cheap factories disappear mid-production, deliver goods months late, or use inferior materials without telling the client. The small amount of money saved on the unit price is nothing compared to the cost of a ruined production run and a damaged reputation. Look for a partner who communicates clearly, shares your values (like our focus on quality and ethics), and is transparent about their process. A slightly higher price from a reliable, high-quality partner is an investment in peace of mind and the long-term health of your brand.

How to Choose the Right Partner

- Communication: Do they respond to emails promptly and clearly? Do they have English-speaking staff?

- Expertise: Do they specialize in lingerie? Can they show you examples of similar, complex products they have made?

- Transparency: Are they open about their process, pricing, and MOQs? Are they willing to show you their certifications (like GRS or OEKO-TEX®)?

- Quality: What are their quality control procedures? Can you speak to some of their other clients?

- Values: Do they have ethical labor practices (e.g., a BSCI audit)? Do they align with your brand's stance on sustainability?

Mistake #7: Are You Hoping for the Best on Quality?

The production run is complete. You're excited to receive your first big shipment. You trust that the factory has done a good job and that every piece will be perfect, so you don't arrange for a final inspection.

Assuming that bulk production quality will automatically match the approved sample is a massive gamble. A formal pre-shipment inspection by a dedicated QC team (either yours or a third party) is the only way to guarantee that your standards have been met before you make the final payment.

Even in the best factories, mistakes can happen over a run of thousands of units. A new sewing machine operator might make an error, a batch of elastic could be slightly defective, or colors might have a slight variation. This is normal. A professional quality control process is designed to catch these issues before they leave the factory. Skipping this step is like buying a used car without having a mechanic look at it first. You might get lucky, or you might get a massive, expensive problem. We have our own multi-stage QC process, but we always welcome and encourage our clients to conduct their own third-party inspections. It builds trust and ensures everyone is aligned on the final product quality.

The AQL Inspection Standard

The industry standard for inspection is AQL (Acceptable Quality Limit).

- It's not about checking every single piece, but a statistically significant random sample from the production run.

- It defines the maximum number of defects allowed for different categories:

- Critical Defects: Unsafe or hazardous (e.g., a broken needle in a garment). The acceptable limit is 0.

- Major Defects: Likely to be noticed by the customer and cause a return (e.g., a hole, a broken seam, incorrect sizing). A common limit is 2.5%.

- Minor Defects: Not likely to be noticed by the customer (e.g., a loose thread, a slightly crooked label). A common limit is 4.0%.

Insisting on an AQL inspection protects both you and the manufacturer, creating a clear, objective standard for what is acceptable for shipment.

Conclusion

Launching a lingerie brand is a challenging but incredibly rewarding journey. By avoiding these seven costly mistakes, you can navigate the path with confidence, protect your investment, and build the brand of your dreams.

Frequently Asked Questions (FAQ)

1. How much money do I need to start a lingerie brand?

This varies massively, but a rough estimate for a small, initial production run, including design, sampling, manufacturing, shipping, marketing, and website setup, can range from $15,000 to $50,000+ USD. Under-capitalization is a major risk.

2. What is the most profitable lingerie item to sell?

While this depends on your brand niche, multi-packs of well-made, comfortable panties often have a good balance of high volume and healthy margins. High-tech shapewear and specialty bras (like post-surgical or maternity) can also command higher prices and margins if you have a strong technical partner.

3. Do I need a patent for my lingerie design?

Generally, you cannot patent a basic clothing design. However, if you've invented a new, unique, and non-obvious functional component—like a novel clasp design or a new type of underwire technology—you might be able to apply for a utility patent. It's best to consult with an intellectual property lawyer.

4. How do I find a good lingerie manufacturer?

You can find manufacturers through online sourcing platforms (like Alibaba, but be cautious), attending trade shows (like Interfilière), and through industry networking. The best approach is to look for partners who are transparent, have strong expertise in lingerie, and can provide verifiable certifications and client references.