How a Great Lingerie Tech Pack Can Save Your Brand Thousands

The difference between a successful lingerie collection and a costly disaster often comes down to one critical document: your tech pack. As an experienced lingerie manufacturer working with over 3,000 stores worldwide, I've seen how a well-prepared tech pack can save brands thousands of dollars, while poor ones lead to endless revisions, production delays, and budget overruns.

A comprehensive tech pack is your brand's universal language with manufacturers, translating your creative vision into precise technical specifications that ensure your lingerie is produced exactly as you imagined—the first time.

Whether you're launching your first collection or looking to streamline your established brand's development process, mastering the art of creating effective tech packs is essential for your bottom line. Let's explore how proper documentation can dramatically reduce costs and accelerate your time to market.

Why Your Tech Pack Is Your Most Valuable Production Asset?

When I first started in the lingerie manufacturing business, I was shocked by how many designers would submit beautiful sketches with minimal technical details, expecting factories to "figure it out." This approach inevitably leads to costly mistakes.

A tech pack isn't just paperwork—it's the blueprint that guides every step of your product's journey from concept to reality. It eliminates guesswork, reduces sampling rounds, and prevents expensive production errors.

The tech pack serves as a contract between your brand and the manufacturer, clearly defining what you expect and what you'll receive.

Without this clarity, manufacturers must make assumptions about your design intentions, often resulting in samples that don't match your vision. Each incorrect sample costs you money and, more critically, time in your development calendar.

The Hidden Costs of Poor Tech Packs: A Financial Black Hole

Let me share a real scenario we encountered last year: A new lingerie brand submitted a tech pack with incomplete measurement specifications for their signature bra. The first sample arrived with cups that were too shallow and straps positioned incorrectly.

After three rounds of sampling at $150 per sample, plus shipping costs and a six-week delay, they finally approved production—but missed their planned launch date, resulting in lost sales opportunities and additional marketing expenses.

The total cost of this inadequate tech pack? Over $5,000 in direct expenses and an estimated $20,000 in lost revenue.

This isn't uncommon. Here's how poor tech packs typically drain your budget:

- Multiple sampling rounds: $100-300 per style, per round

- Express shipping fees: $50-200 per shipment

- Development timeline extensions: 2-8 weeks of delays

- Production rush charges: 10-30% premium on manufacturing costs

- Missed market opportunities: Potentially thousands in lost sales

At HAVING, we've analyzed hundreds of tech packs and found that brands with comprehensive documentation typically require 60% fewer sample revisions and launch collections an average of 5 weeks earlier than those with minimal specifications.

5 Essential Components of an Effective Lingerie Tech Pack

A professional lingerie tech pack must include these five critical elements to minimize costly errors and streamline production:

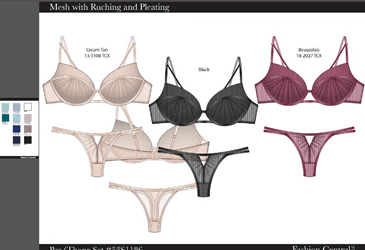

1. Technical Flat Sketches

Unlike fashion illustrations, technical flats are detailed, proportional drawings that show exactly how your garment should be constructed. For lingerie, these must include:

- Front and back views

- Side views for bras and shapewear

- Close-up details of special construction elements

- Accurate representation of seam lines, topstitching, and hardware placement

Pro tip: Always include both colored and black-and-white versions of your flats. The colored version helps visualize the final product, while the black-and-white version ensures construction details are clearly visible.

2. Comprehensive Measurement Specifications

Lingerie requires extremely precise measurements, often down to the millimeter. Your spec sheet should include:

- A detailed points of measure (POM) diagram

- Measurements for each size in your range

- Tolerances for each measurement point

- Specific instructions for measuring curved elements like underwires and cups

Common costly mistake: Failing to specify the correct measuring method for stretch fabrics (relaxed vs. extended) can result in garments that fit completely differently than intended.

3. Bill of Materials (BOM)

Your BOM should list every component needed to produce your garment:

- Main fabrics with exact composition percentages

- Lining and interlining materials

- Elastics (width, stretch percentage, and composition)

- Hardware (hooks, rings, sliders, underwires)

- Thread types and colors for each operation

- Trims and decorative elements

Cost-saving tip: Specify alternative materials that would be acceptable if your first choice is unavailable. This prevents production delays while waiting for your approval on substitutions.

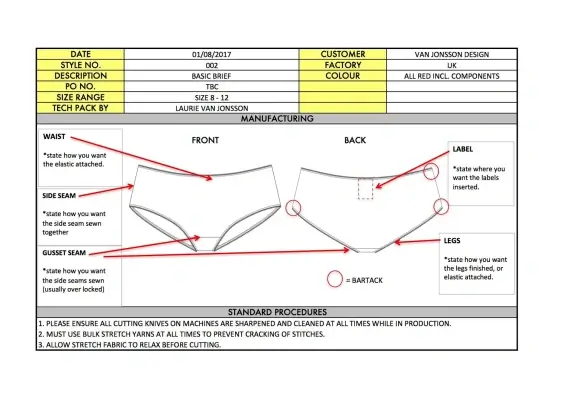

4. Construction and Sewing Instructions

This section details how your garment should be assembled:

- Seam types for each construction point

- Stitch density requirements

- Elastic application methods

- Special handling instructions for delicate materials

- Order of operations for complex construction elements

Critical detail: For lingerie, specifying the correct elastic tension is essential. Include percentages (e.g., "apply elastic with 15% tension") rather than subjective terms like "slight tension."

5. Packaging and Labeling Requirements

Often overlooked but crucial for your brand presentation:

- Hang tag placement and attachment method

- Care label content and placement

- Size label specifications

- Packaging instructions (poly bags, boxes, tissue paper)

- Barcode requirements

Branding opportunity: Detailed packaging instructions ensure your customer's unboxing experience matches your brand's positioning and quality standards.

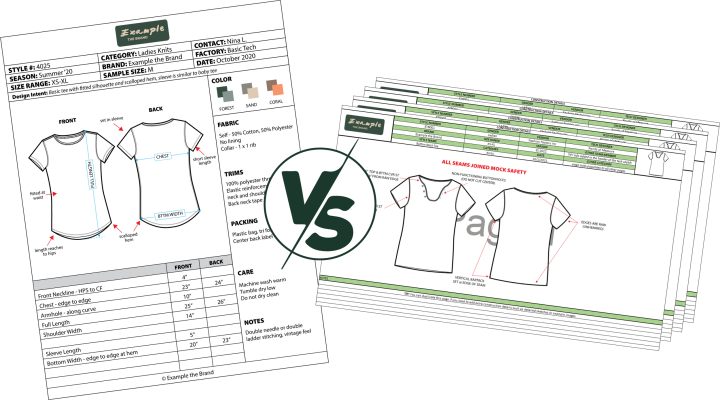

Case Study: The $8,000 Difference Between Poor and Professional Tech Packs

To illustrate the financial impact of tech pack quality, let's compare two real lingerie brands we worked with last year (names changed for privacy):

| Process Element | Brand A (Basic Tech Pack) | Brand B (Comprehensive Tech Pack) |

|---|---|---|

| Initial Tech Pack Quality | Hand sketches, basic measurements, minimal construction details | Professional technical flats, detailed POM, comprehensive BOM, specific construction instructions |

| Sample Rounds Required | 4 rounds ($600) | 1 round ($150) |

| Development Timeline | 16 weeks | 6 weeks |

| Express Shipping Costs | $450 (multiple urgent shipments) | $100 (standard shipping) |

| Production Delays | 3 weeks (missed seasonal window) | None |

| Material Waste | 15% excess due to unclear specifications | 3% standard waste |

| Total Additional Costs | $8,750 | $750 |

The difference is striking: Brand A spent an additional $8,000 and lost 10 weeks of market time due to their inadequate tech pack. Meanwhile, Brand B launched on schedule with minimal revisions, allowing them to capitalize on their planned marketing campaign and seasonal retail placement.

Decoding Lingerie Technical Terminology: Speaking the Factory's Language

One common source of costly misunderstandings is terminology confusion. Here are five frequently misinterpreted terms in lingerie tech packs and how to clarify them:

1. "Soft Cup" vs. "Non-Wired Cup"

Problem: "Soft cup" can be interpreted as either a non-wired cup or a cup with soft padding.

Solution: Specify "non-wired, unpadded cup" or "non-wired cup with 3mm foam padding" to avoid confusion.

2. "Picot Edge" vs. "Scalloped Edge"

Problem: These terms are often used interchangeably but refer to different finishing techniques.

Solution: Include a reference image of the exact edge finish you want, with measurements of the scallop depth or picot size.

3. "Medium Stretch" vs. "50% Stretch"

Problem: Subjective stretch descriptions lead to inconsistent results.

Solution: Always specify stretch as a percentage (e.g., "fabric must stretch 50% in width direction and 20% in length direction").

4. "Lightweight Lining" vs. "15 GSM Power Mesh"

Problem: Subjective material descriptions leave room for interpretation.

Solution: Specify exact material weights (GSM - grams per square meter) and composition percentages.

5. "Seamless" vs. "Bonded Seams"

Problem: "Seamless" can refer to knitted seamless construction or garments with bonded/welded seams.

Solution: Specify "circular knit seamless construction" or "cut-and-sew with ultrasonic bonded seams" to clarify your requirements.

Conclusion: Invest in Your Tech Pack, Invest in Your Success

A professional lingerie tech pack is not an administrative burden—it's a strategic investment that yields significant returns through reduced development costs, faster time to market, and higher-quality products.

At HAVING, we've seen brands transform their production efficiency by simply improving their technical documentation. The upfront effort of creating detailed tech packs typically saves 15-20% on overall development and production costs while reducing time to market by 30-40%.

For emerging lingerie brands with limited resources, investing in professional tech pack development may seem expensive initially, but it's far more costly to correct production mistakes after they occur. Consider working with an experienced technical designer to create your first tech packs, then use these as templates for future styles.

Remember: Your tech pack is the foundation upon which your entire production process is built. Make it solid, clear, and comprehensive, and you'll reap the rewards of smoother production, lower costs, and higher-quality lingerie that delights your customers.

Frequently Asked Questions (FAQ)

What's the minimum information I need to include in a lingerie tech pack?

At minimum, your tech pack should include technical flat sketches (front and back), a complete measurement chart with tolerances, a bill of materials listing all components, basic construction notes, and labeling requirements. However, for best results, we recommend including all five essential components detailed in this article.

How detailed should my construction instructions be?

For lingerie, which often involves complex construction techniques, your instructions should be detailed enough that a factory unfamiliar with your brand could produce your garment correctly. Include stitch types, seam finishes, elastic tensions, and assembly order for complex elements.

Should I create separate tech packs for each colorway of the same style?

You should create one master tech pack for the style with a colorway section that clearly shows all color options. Include Pantone color codes for each component and note any construction differences between colorways (such as different lace patterns or hardware finishes).

How can I ensure my measurements are interpreted correctly?

Always include a clear points of measure (POM) diagram showing exactly where each measurement should be taken. Specify whether measurements should be taken flat or in the round, and note any special measuring techniques for stretch materials or curved elements.

What file format should I use for my tech pack?

Most manufacturers prefer to receive tech packs as PDF files, which preserve formatting across different computer systems. However, you should also maintain an editable version (in Excel, Adobe Illustrator, or specialized tech pack software) for future updates and style variations.