From Factory to Warehouse: Understanding MOQs, Lead Times & Logistics in Activewear & Yoga Wear Sourcing?

Supply chain complexities often catch businesses by surprise. Unexpected lead times, shipping delays, and customs issues can disrupt inventory planning and disappoint customers who are waiting for your activewear products.

Successful activewear sourcing requires understanding typical lead times (60-90 days from order to delivery), minimum order quantities (typically 500-3,000 units per style depending on customization), and international shipping considerations. Planning for these factors prevents inventory shortages and ensures smooth product launches.

At HAVING, we've streamlined our supply chain processes to provide predictability for our partners. Our experience scaling production to over $30 million in annual sales serving more than 3,000 stores has taught us valuable lessons about managing the logistics of activewear sourcing. Let me share what we've learned about navigating these critical supply chain elements.

What Minimum Order Quantities Should You Expect?

Minimum order quantities (MOQs) are often the first hurdle businesses face when sourcing activewear. Without understanding typical requirements, it's easy to be surprised by minimums that exceed your initial budget or storage capacity.

Minimum order quantities for activewear typically range from 500-3,000 units per style/color depending on customization level. Factors influencing MOQs include material selection (stock vs. custom), design complexity, manufacturing efficiency requirements, and your relationship status with the manufacturer.

When we first started manufacturing activewear at HAVING, we maintained high MOQs due to production complexity. Today, we've developed more flexible options to accommodate various business sizes while maintaining quality and efficiency. Here's what you need to know about MOQs:

MOQ Factors and Typical Requirements

| Factor | Lower MOQ Range | Higher MOQ Range |

|---|---|---|

| Customization Level | Standard designs with branding: 500 units | Fully custom designs: 2,000-3,000 units |

| Material Selection | Stock materials: 500-1,000 units | Custom-developed materials: 3,000+ units |

| Color Options | Standard colors: 500 units per color | Custom dyed colors: 1,000+ units per color |

| Product Complexity | Basic styles (leggings, tanks): Lower MOQs | Complex styles (jackets, bras): Higher MOQs |

MOQ Strategies for Different Business Sizes

Startups and Small Brands

If you're just entering the activewear market, consider these approaches:

- Start with ODM (Original Design Manufacturing) using the manufacturer's existing designs with your branding

- Focus on 1-2 core styles in 1-2 colors to meet minimum requirements

- Consider stock materials rather than custom-developed fabrics

- Partner with manufacturers offering lower MOQs for standard designs

At HAVING, we offer industry-leading low MOQs of just 500 pieces per style for standard designs with branding, making private label accessible to emerging brands.

Medium-Sized Brands

As your business grows, you can optimize MOQs through:

- Consolidating orders for multiple styles to reach volume discounts

- Developing a core color program with seasonal accent colors

- Balancing custom and standard elements to manage minimums

- Building consistent ordering patterns to negotiate lower MOQs

Large Retailers

For substantial volume buyers:

- Negotiate MOQs based on annual purchase commitments

- Develop exclusive materials with suppliers through volume guarantees

- Create staggered delivery schedules to manage production flow

- Establish vendor-managed inventory programs with manufacturers

For detailed information on developing your own activewear line, visit our comprehensive guide: Your Brand, Your Product: The Complete Guide to Private Label (OEM/ODM) Activewear & Yoga Wear Manufacturing.

What Lead Times Should You Plan For?

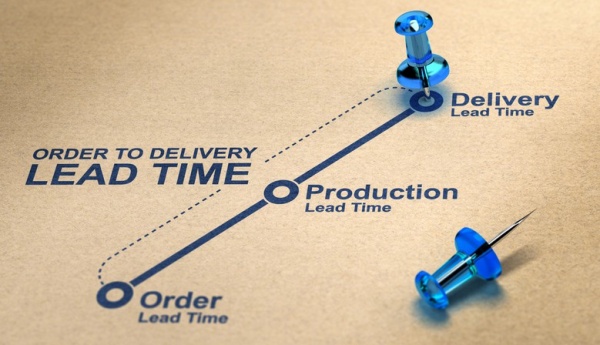

Unrealistic lead time expectations can derail product launches and marketing plans. Many businesses underestimate the time required from order placement to delivery, leading to inventory shortages and disappointed customers.

The typical timeline for activewear production includes sampling (2-3 weeks), material sourcing (3-4 weeks), production (4-6 weeks), quality control and testing (1 week), and shipping (2-6 weeks depending on destination and method). Planning for a total lead time of 12-20 weeks from concept to delivery ensures realistic inventory management.

At HAVING, we provide transparent lead time estimates based on our extensive manufacturing experience. Here's a detailed breakdown of the timeline components:

Development and Sampling Phase

Initial Sampling: 2-3 weeks

- Design confirmation: 3-5 days

- Material preparation: 5-7 days

- Sample production: 5-7 days

- Sample evaluation and feedback: 3-5 days

Revised Sampling (if needed): 1-2 weeks

- Adjustment implementation: 3-5 days

- Revised sample production: 5-7 days

- Final approval: 2-3 days

Pre-Production Phase

Material Sourcing: 3-4 weeks

- Fabric procurement: 2-3 weeks

- Trims and elastics: 2-3 weeks

- Color matching and approval: 1-2 weeks

Production Setup: 1-2 weeks

- Pattern grading and marker making: 3-5 days

- Production planning: 3-5 days

- Pre-production sample approval: 3-5 days

Production Phase

Bulk Production: 4-6 weeks

- Cutting: 5-7 days

- Sewing and assembly: 15-25 days

- Quality control during production: Ongoing

- Finishing and trimming: 3-5 days

Final Quality Control: 1 week

- Final inspection: 3-5 days

- Testing of production samples: 3-5 days

- Packaging and preparation for shipping: 2-3 days

Shipping Phase

Shipping Time: 2-6 weeks

- Air freight: 5-10 days (including customs clearance)

- Sea freight: 3-6 weeks (including customs clearance)

- Land transportation to final destination: 2-7 days

Lead Time Variables

Several factors can impact lead times:

| Variable | Potential Impact | Mitigation Strategy |

|---|---|---|

| Seasonal Timing | +1-3 weeks during peak seasons | Order during industry off-seasons |

| Material Availability | +2-4 weeks for specialty materials | Confirm material availability before ordering |

| Order Complexity | +1-2 weeks for complex designs | Simplify initial orders to establish baseline |

| Shipping Disruptions | Unpredictable delays | Build buffer time into planning |

For insights on market trends that might affect your inventory planning, visit our detailed analysis: Understanding the Activewear & Yoga Wear Market: Trends, Demographics & Opportunities for B2B Buyers.

International shipping complexities can significantly impact costs and timelines. Many businesses encounter unexpected fees, customs delays, and compliance issues when importing activewear.

Effective international shipping for activewear requires understanding shipping terms (FOB, EXW, DDP), selecting appropriate freight methods based on timeline and budget, preparing proper documentation for customs clearance, and planning for duties and taxes that can add 15-30% to product costs.

At HAVING, we help our partners navigate the complexities of international shipping and logistics. Here's what you need to know:

Shipping Terms and Responsibilities

Understanding shipping terms is crucial for clear responsibility allocation:

FOB (Free On Board)

- Manufacturer Responsibility: Delivery of goods to designated port/vessel

- Buyer Responsibility: International freight, insurance, customs clearance, final delivery

- Advantages: Lower upfront cost, control over shipping method

- Best For: Experienced importers with established freight forwarders

EXW (Ex Works)

- Manufacturer Responsibility: Making goods available at their facility

- Buyer Responsibility: All transportation, export/import clearance, insurance

- Advantages: Potentially lowest price point, complete control

- Best For: Buyers with strong logistics capabilities or local agents

DDP (Delivered Duty Paid)

- Manufacturer Responsibility: All transportation, customs clearance, duties, delivery to final destination

- Buyer Responsibility: Receiving goods at designated location

- Advantages: Simplicity, predictable landed cost

- Best For: Businesses new to importing or seeking simplicity

Freight Methods Comparison

| Method | Timeline | Cost | Best For |

|---|---|---|---|

| Air Freight | 5-10 days | High ($5-10/kg) | Urgent shipments, low volume, high-value goods |

| Express Courier | 3-7 days | Very High ($10-20/kg) | Samples, very small shipments, extreme urgency |

| Sea Freight (FCL) | 30-45 days | Low ($0.5-1.5/kg) | Large shipments filling a container |

| Sea Freight (LCL) | 35-50 days | Medium ($1.5-3/kg) | Medium-sized shipments not filling a container |

Documentation Requirements

Proper documentation is essential for smooth customs clearance:

Essential Documents

- Commercial Invoice: Detailed description, quantities, values

- Packing List: Itemized contents by carton/pallet

- Bill of Lading/Airway Bill: Transport document

- Certificate of Origin: Verifies country of manufacture

- Textile Declaration: Fiber content information

Additional Documentation (Market Specific)

- Lab Test Reports: Safety testing documentation

- OEKO-TEX Certificates: Verification of safety standards

- Compliance Declarations: Market-specific requirements

- Import Licenses: Required in some countries

Duties, Taxes, and Additional Costs

When calculating landed costs, consider these additional expenses:

Import Duties

- Classification: Activewear typically falls under HS code 6112 or 6114

- Duty Rates: Vary by country (typically 5-20% of product value)

- Trade Agreements: May provide reduced or zero duties

Taxes

- Value Added Tax (VAT): Applied in many countries (typically 10-25%)

- Goods and Services Tax (GST): Applied in countries like Australia, Canada

- Sales Tax: Applied in the US at state/local level

Additional Costs

- Customs Broker Fees: $100-300 per shipment

- Harbor Maintenance Fees: For sea shipments to certain countries

- Merchandise Processing Fees: Administrative charges

- Storage/Demurrage: Charges for delayed container pickup

- Last-Mile Delivery: Transportation to final destination

For information on quality control processes that should occur before shipping, visit our resource on Ensuring Product Excellence: Quality Control & Manufacturing Standards for Activewear & Yoga Wear Sourcing.

How Do You Manage Inventory Effectively?

Poor inventory management leads to either excess stock tying up capital or stockouts disappointing customers. Many businesses struggle to balance these competing risks when dealing with long lead times.

Effective activewear inventory management combines data-driven forecasting, strategic safety stock levels (typically 30-60 days supply), and tiered inventory classification (core styles maintained at higher stock levels than seasonal items). Implementing reorder points based on lead times rather than arbitrary levels helps prevent stockouts while minimizing excess inventory.

At HAVING, we help our partners develop inventory strategies that balance availability with capital efficiency. Here's our approach to effective inventory management:

Inventory Forecasting Methods

Accurate forecasting is the foundation of inventory management:

Historical Sales Analysis

- Baseline Method: Using past sales to project future demand

- Growth Factor: Applying category growth rates to historical data

- Seasonality Adjustments: Accounting for cyclical demand patterns

Market-Based Forecasting

- Market Share Approach: Estimating total market size and your share

- Competitive Analysis: Monitoring competitor activity and impact

- Trend Incorporation: Adjusting for emerging market trends

New Product Forecasting

- Comparable Product Method: Using similar product performance as baseline

- Test Market Data: Extrapolating from limited market testing

- Pre-Order Information: Using customer commitments as indicators

Inventory Classification Strategy

Not all activewear styles require the same inventory approach:

| Category | Description | Inventory Strategy |

|---|---|---|

| Core Products | Staple styles, consistent sellers | Higher safety stock (60-90 days), regular replenishment |

| Seasonal Products | Fashion colors, limited editions | Lower safety stock (30-45 days), one-time purchasing |

| New Launches | First-time offerings | Conservative initial order, rapid reorder capability |

| Specialty Items | Niche products (e.g., specialized yoga items) | Just-in-time approach, demand-driven ordering |

Reorder Point Calculation

To determine when to place new orders:

Reorder Point = (Average Daily Sales × Lead Time in Days) + Safety Stock

Example calculation:

- Average daily sales: 20 units

- Lead time: 90 days

- Safety stock: 30 days' worth (600 units)

- Reorder point: (20 × 90) + 600 = 2,400 units

When inventory drops to 2,400 units, place a new order.

Seasonal Planning Strategies

Activewear often has seasonal demand patterns requiring specialized approaches:

- Forward Buying: Purchasing seasonal inventory 4-6 months in advance

- Phased Deliveries: Arranging staggered shipments to match sales curve

- End-of-Season Strategy: Planning markdown timing and depth

- Carryover Analysis: Identifying which seasonal items could become core

For insights on building a balanced product line that optimizes inventory efficiency, visit our guide on Curating Your Collection: A B2B Guide to Activewear & Yoga Wear Styles, Functions & Material Options.

Conclusion

Successfully navigating MOQs, lead times, and logistics is essential for efficient activewear sourcing. By understanding manufacturer requirements, planning realistic timelines, managing international shipping complexities, and implementing effective inventory strategies, businesses can ensure consistent product availability while optimizing capital utilization.

At HAVING, we partner with brands to create streamlined supply chains that balance efficiency with flexibility, helping our clients succeed in the competitive activewear market.

For a comprehensive overview of the entire activewear category, including market trends and business opportunities, visit our Ultimate B2B Guide to Sourcing & Selling Activewear & Yoga Wear.

Frequently Asked Questions (FAQ)

What's the smallest order quantity possible for activewear?

The absolute minimum typically starts at 500 units per style/color for standard designs with basic branding. Smaller quantities may be possible for sample runs or through aggregators who combine multiple small orders, but unit costs will be significantly higher.

How can I reduce lead times for activewear production?

To reduce lead times, consider using stock materials rather than custom fabrics, work with manufacturers who maintain common components, develop standardized designs that require less setup time, and build long-term relationships that may provide priority production scheduling.

What's the most cost-effective shipping method for activewear?

Sea freight is typically the most cost-effective for larger orders (500+ units), with costs 70-80% lower than air freight. However, the extended transit time (30-45 days versus 5-10 days for air) requires more advanced planning and higher safety stock levels.

How do I calculate import duties for activewear?

Import duties vary by country and are typically calculated as a percentage of the product's value (usually 5-20%). Consult with a customs broker for specific rates in your market, and check if any free trade agreements apply that might reduce or eliminate duties.

What inventory turnover ratio should I target for activewear?

A healthy inventory turnover ratio for activewear typically ranges from 4-6 turns per year for core styles and 6-8 turns for seasonal items. This balances capital efficiency with adequate stock levels to prevent stockouts.

How do seasonal factors affect activewear sourcing?

Manufacturing capacity is often constrained during peak production seasons (typically August-November for holiday merchandise). Plan orders during off-peak periods when possible, and expect potential delays or higher MOQs during busy seasons.