Your Brand, Your Product: The Complete Guide to Private Label (OEM/ODM) Activewear & Yoga Wear Manufacturing?

Many businesses hesitate to develop their own branded activewear due to perceived complexity. They miss the higher margins and brand loyalty that come with private label offerings, settling instead for reselling existing brands at lower profit margins.

Private label activewear allows businesses to control branding, pricing, and product specifications while achieving higher profit margins (typically 50-70% versus 30-40% for reselling). OEM/ODM manufacturing partners handle the technical aspects while you focus on marketing and distribution, creating a unique offering that builds customer loyalty.

At HAVING, we've guided numerous brands through the process of developing their own private label activewear lines. Our journey to $30 million in annual sales serving over 3,000 stores has given us deep insights into successful private label development. Let me share what we've learned about creating your own branded activewear products.

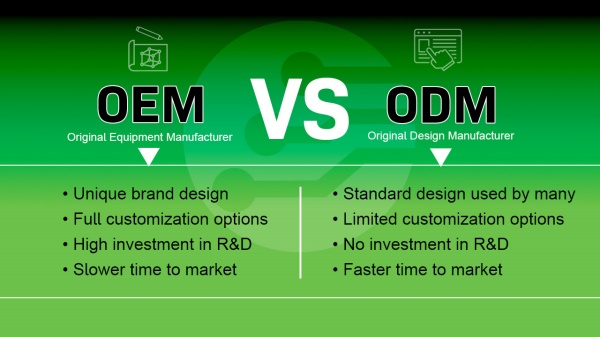

What's the Difference Between OEM and ODM Manufacturing?

Understanding these two manufacturing approaches is the first step in developing your private label strategy. Many businesses aren't clear on which option best suits their needs and capabilities.

OEM (Original Equipment Manufacturing) involves providing detailed specifications to a manufacturer who produces according to your requirements—ideal for brands with clear design vision and technical knowledge. ODM (Original Design Manufacturing) utilizes the manufacturer's existing designs with your branding applied—perfect for faster market entry with reduced development costs.

At HAVING, we offer both manufacturing approaches to accommodate different business needs and capabilities. Here's a detailed comparison to help you determine which approach is right for your brand:

OEM Manufacturing (Original Equipment Manufacturing)

Definition: You provide detailed specifications and designs; we manufacture according to your requirements.

Advantages:

- Complete control over product specifications

- Unique products exclusive to your brand

- Differentiation from competitors

- Ability to implement specific innovations

Considerations:

- Requires more technical knowledge

- Longer development timeline

- Higher development costs

- Typically higher minimum order quantities (MOQs)

Best For:

- Established brands with clear vision

- Businesses with technical expertise

- Brands seeking significant differentiation

- Companies with previous apparel experience

ODM Manufacturing (Original Design Manufacturing)

Definition: We provide existing designs that you can customize with your branding.

Advantages:

- Faster time to market

- Lower development costs

- Proven designs with tested performance

- Lower minimum order quantities

- Reduced technical requirements

Considerations:

- Less product uniqueness

- Limited differentiation from competitors

- Less control over technical specifications

Best For:

- New market entrants

- Brands testing the activewear category

- Businesses with limited technical resources

- Companies seeking faster launch timelines

Hybrid Approach

Many of our most successful partners use a hybrid approach:

- Start with ODM for initial market entry

- Gather customer feedback and sales data

- Gradually transition to OEM for unique features

- Develop proprietary elements while maintaining proven components

This strategy minimizes risk while allowing for increasing differentiation over time.

For detailed information on activewear technology and materials that inform product development decisions, visit our comprehensive guide: Activewear & Yoga Wear Technology & Materials: A Buyer's Guide to Performance Fabrics, Construction & Durability.

What's the Process for Developing Private Label Activewear?

The development process can seem daunting without a clear roadmap. Many businesses underestimate the time and steps required, leading to rushed decisions and suboptimal products.

The private label development process typically takes 3-6 months and includes: initial consultation and concept development (1-2 weeks), material selection and technical specification (2-3 weeks), sampling and revisions (4-6 weeks), production preparation (2-3 weeks), and manufacturing (4-6 weeks). Each stage requires clear communication and decision-making to ensure the final product meets expectations.

At HAVING, we've streamlined our development process based on experience with numerous private label partners. Here's our step-by-step approach:

Phase 1: Consultation & Concept Development (1-2 Weeks)

Key Activities:

- Initial consultation to understand brand vision

- Target market and positioning discussion

- Preliminary style and function planning

- Budget and timeline establishment

- Competitive analysis and market positioning

Deliverables:

- Project brief

- Preliminary product specifications

- Development timeline

- Initial pricing estimates

Phase 2: Material Selection & Technical Specification (2-3 Weeks)

Key Activities:

- Fabric selection based on performance requirements

- Color and trim selection

- Construction method determination

- Technical specification development

- Pricing refinement

Deliverables:

- Material swatches

- Technical specification sheets

- Component list

- Revised pricing estimates

Phase 3: Sampling & Revisions (4-6 Weeks)

Key Activities:

- Development of initial prototypes

- Fit assessment

- Performance testing

- Design refinements

- Final sample approval

Deliverables:

- Initial prototypes

- Test reports

- Revised samples

- Final approved samples

- Production-ready specifications

Phase 4: Production Preparation (2-3 Weeks)

Key Activities:

- Material procurement

- Production planning

- Quality control protocol establishment

- Packaging development

- Pre-production approval

Deliverables:

- Production schedule

- Quality control standards

- Packaging samples

- Pre-production samples

Phase 5: Manufacturing (4-6 Weeks)

Key Activities:

- Bulk production

- In-line quality control

- Final inspection

- Packaging and labeling

- Shipping preparation

Deliverables:

- Finished products

- Quality control reports

- Shipping documentation

For insights on building a complete activewear product line, visit our guide on Curating Your Collection: A B2B Guide to Activewear & Yoga Wear Styles, Functions & Material Options.

What Customization Options Are Available for Private Label Activewear?

Understanding customization possibilities helps businesses create truly distinctive products. Many aren't aware of the full range of options available beyond basic branding.

Activewear customization options include fabric selection (performance level, composition, weight), color development, print design, construction techniques, branding elements (logos, labels, heat transfers), packaging design, and functional features (pockets, mesh panels, special seaming). The level of customization typically correlates with minimum order quantities and development timelines.

At HAVING, we offer extensive customization options for our private label partners. Here's an overview of the key areas where you can differentiate your products:

Material Customization

Fabric Options

- Performance Levels: Basic, moderate, or advanced moisture management

- Composition: Polyester/elastane, nylon/elastane, sustainable blends

- Weight: Lightweight for high-intensity, midweight for studio, heavyweight for compression

- Hand Feel: Silky, cottony, brushed, compressive

- Special Properties: UV protection, anti-odor, quick-dry, extra stretch

Color and Print Options

- Solid Colors: Custom color matching to your specifications

- Heathered Effects: Marled or space-dyed appearances

- All-Over Prints: Custom patterns, digital printing

- Placement Prints: Strategic design placement

- Specialty Finishes: Matte, shine, or textured effects

Design Customization

Style Options

- Silhouette Modifications: Adjusting rise height, leg shape, strap design

- Construction Details: Seam placement, panel design, gusset shape

- Functional Elements: Pocket addition or modification, mesh panel placement

- Performance Features: Compression zones, ventilation placement

Branding Elements

- Logo Application: Printing, embroidery, heat transfer, silicone

- Label Design: Main labels, care labels, size labels

- Hardware: Zipper pulls, cord ends, snaps with logo

- Elastic Treatments: Branded waistbands, custom elastic colors

Packaging Customization

- Hang Tags: Custom design, shape, material

- Product Packaging: Poly bags, boxes, sustainable alternatives

- Collateral Materials: Inserts, care instructions, brand storytelling

- Bundling Options: Sets, multi-packs, gift-ready packaging

Customization Levels

We typically offer three levels of customization:

| Customization Level | What's Included | Typical MOQ |

|---|---|---|

| Basic Branding | Standard designs with your labels, logos, packaging | 500 units |

| Moderate Customization | Color changes, material selection, basic design modifications | 1,000-3,000 units |

| Full Customization | Unique designs, custom materials, specialized features | 3,000+ units |

For information on quality control standards for private label products, visit our resource on Ensuring Product Excellence: Quality Control & Manufacturing Standards for Activewear & Yoga Wear Sourcing.

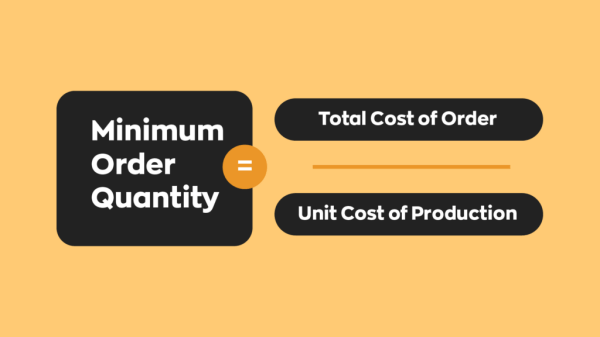

What Are the Minimum Order Quantities and Cost Considerations?

Understanding MOQs and cost factors is crucial for financial planning. Many businesses are surprised by minimum order requirements or don't fully understand the factors that influence pricing.

Minimum order quantities for private label activewear typically range from 500-3,000 units per style/color depending on customization level. Key cost factors include fabric selection (technical features increase cost), construction complexity (more panels and specialized seaming increase cost), customization degree, order volume (larger orders reduce unit cost), and packaging complexity.

At HAVING, we've structured our private label program to accommodate various business sizes while maintaining quality standards. Here's what you need to know about MOQs and pricing:

Minimum Order Quantities

Our MOQ structure is designed to be accessible while ensuring production efficiency:

By Business Size

- Small Brands/Startups: 500 units per style

- Medium Brands: 1,000-3,000 units per style

- Large Retailers: 3,000+ units per style

By Customization Level

- Standard Designs with Branding: 500 units per style/color

- Modified Standard Designs: 1,000 units per style/color

- Fully Custom Designs: 2,000-3,000 units per style/color

By Material Type

- Stock Materials: Lower MOQs (500-1,000)

- Custom-Dyed Standard Materials: Medium MOQs (1,000-2,000)

- Custom-Developed Materials: Higher MOQs (3,000+)

Cost Factors

Several elements influence the final cost of private label activewear:

Material Selection

| Material Type | Relative Cost Impact |

|---|---|

| Basic Polyester/Elastane | Baseline |

| Premium Nylon/Elastane | +15-25% |

| Recycled Materials | +10-20% |

| Technical Performance Fabrics | +20-40% |

Construction Complexity

- Basic Construction: Minimal panels, standard seaming (baseline cost)

- Moderate Complexity: Multiple panels, some specialized seaming (+10-20%)

- High Complexity: Numerous panels, extensive specialized seaming (+20-30%)

- Technical Construction: Bonded seams, complex paneling, special features (+30-50%)

Order Volume

Volume discounts typically follow this pattern:

- 500-1,000 units: Base price

- 1,001-3,000 units: 5-10% discount

- 3,001-5,000 units: 10-15% discount

- 5,001-10,000 units: 15-20% discount

- 10,000+ units: 20%+ discount (negotiable)

Packaging Options

- Basic Poly Bag: Minimal cost

- Custom Printed Poly Bag: Low additional cost

- Hang Tags and Inserts: Low to medium additional cost

- Custom Boxes: Medium to high additional cost

Price Range Examples

While specific pricing depends on many factors, here are typical wholesale price ranges:

- Basic Private Label: $8-12 per unit

- Mid-Range Private Label: $12-18 per unit

- Premium Private Label: $18-25+ per unit

For insights on pricing strategy and profit margins, explore our detailed analysis: Maximizing Your ROI: Activewear & Yoga Wear Wholesale Pricing, Retail Margins & Profitability Analysis.

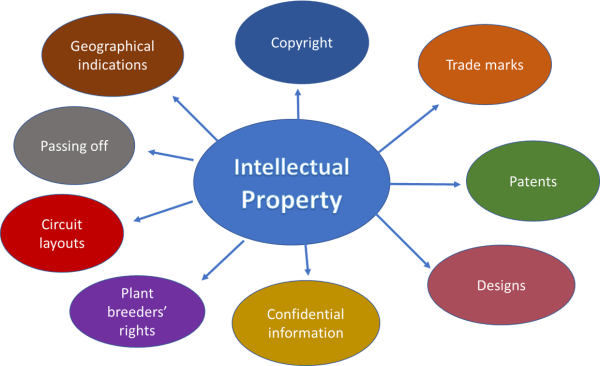

How Do You Protect Your Brand and Intellectual Property?

Intellectual property concerns often arise when developing private label products. Many businesses worry about design protection and exclusivity when working with overseas manufacturers.

Protecting your brand and intellectual property involves several strategies: clear confidentiality agreements, limited distribution of technical specifications, trademark registration in key markets, design patents for truly innovative features, and working with reputable manufacturers with established IP protection protocols.

At HAVING, we respect our partners' intellectual property and have established protocols to protect their designs and innovations. Here are key strategies we recommend:

Legal Protection Measures

Confidentiality Agreements

- Non-Disclosure Agreements (NDAs): Sign before sharing designs or concepts

- Confidentiality Clauses: Include in all manufacturing agreements

- Information Classification: Clearly mark confidential documents

Intellectual Property Registration

- Trademark Registration: Register your brand name and logo in manufacturing countries

- Design Patents: Consider for truly unique functional or aesthetic elements

- Utility Patents: For innovative technical solutions (rare in activewear)

Contractual Protections

- Exclusivity Clauses: Prevent manufacturing of identical products for competitors

- Ownership Clauses: Clearly establish ownership of designs and specifications

- Non-Compete Provisions: Restrict manufacturer from entering your market directly

Practical Protection Strategies

Information Management

- Need-to-Know Basis: Limit complete design access to essential personnel

- Compartmentalization: Divide production knowledge among different teams

- Digital Security: Use secure file sharing and communication methods

Manufacturing Relationship

- Reputation Research: Work with manufacturers with established reputations

- Reference Checks: Speak with current clients about IP protection experiences

- Ongoing Monitoring: Regular market checks for unauthorized copies

Production Safeguards

- Production Counting: Strict accounting of all materials and finished goods

- Quality Mark Systems: Hidden identifiers in authentic products

- Destruction of Seconds: Proper disposal of rejected products

For information on navigating supply chain and logistics considerations, visit our guide on From Factory to Warehouse: Understanding MOQs, Lead Times & Logistics in Activewear & Yoga Wear Sourcing.

What Are the Benefits of Partnering with HAVING for Private Label Activewear?

Finding the right manufacturing partner is crucial for private label success. Many suppliers lack the specialized expertise needed for technical activewear products.

The ideal activewear manufacturing partner combines technical expertise in performance fabrics, proven quality control systems, competitive pricing, and flexible MOQs. Look for manufacturers with demonstrated success in scaling production, a commitment to quality, and a collaborative approach to product development.

At HAVING, we've established ourselves as a leader in activewear manufacturing through our work with major retailers and brands. Our journey to $30 million in annual sales serving over 3,000 stores demonstrates our ability to scale while maintaining quality.

Our Unique Advantages

What sets HAVING apart:

-

"Body-Before-Fabric" Philosophy: Our design approach prioritizes comfort, fit, and performance, ensuring garments move with the body rather than restricting it.

-

Low MOQ Flexibility: We offer industry-leading low minimums of just 500 pieces per style, making private label accessible to businesses of all sizes.

-

Technical Expertise: Our specialized knowledge of performance fabrics and construction techniques ensures products that perform as promised.

-

Comprehensive Support: We guide partners through the entire development process, from concept to delivery.

-

Proven Scale: With $30 million in annual sales and over 3,000 stores served, we have demonstrated our ability to deliver consistent quality at volume.

Our Private Label Process

Working with HAVING is straightforward:

- Consultation: We discuss your brand vision, target market, and product needs

- Design & Development: We create or adapt designs to meet your specifications

- Sampling: We produce prototypes for your approval

- Production: We manufacture your products with rigorous quality control

- Delivery: We manage logistics to get products to your warehouse efficiently

Conclusion

Developing your own private label activewear offers significant advantages in terms of brand control, margin potential, and market differentiation. By understanding the OEM/ODM process, customization options, cost considerations, and intellectual property protection strategies, businesses can successfully create unique products that build customer loyalty and drive profitability.

At HAVING, we're committed to supporting your private label journey with our manufacturing expertise and collaborative approach to product development.

For a comprehensive overview of the entire activewear category, including market trends and business opportunities, visit our Ultimate B2B Guide to Sourcing & Selling Activewear & Yoga Wear.

Frequently Asked Questions (FAQ)

What's the difference between private label and white label activewear?

Private label typically involves more customization and unique specifications tailored to your brand, while white label refers to standard products manufactured by a supplier that you simply add your branding to with minimal changes.

How long does it take to develop a private label activewear line?

The complete process typically takes 3-6 months from initial concept to finished product, with timeline variations based on customization level, material selection, and order complexity.

What's the minimum investment needed to start a private label activewear line?

For a basic collection (2-3 styles in 2 colorways), expect minimum investment of $8,000-15,000 depending on customization level, material selection, and order quantities.

Can I make small changes to existing designs without meeting full custom MOQs?

Yes, many manufacturers including HAVING offer modified standard designs with lower MOQs than fully custom products. This "hybrid approach" allows for some differentiation without the higher minimums of completely custom designs.

How do I ensure quality control for my private label products?

Work with manufacturers that have established quality control processes, request detailed testing reports, consider third-party inspections for large orders, and start with smaller production runs to verify quality before scaling.

What information do I need to provide to start the private label process?

Be prepared to share your target market, desired price points, style preferences, performance requirements, branding elements, packaging ideas, and timeline expectations. The more specific your vision, the more efficiently the development process can proceed.