Lingerie Fabric Face-Off: Pros, Cons & Cost Considerations for Diverse Materials

The fabric choice for your lingerie line can make or break your business. Poor selections lead to uncomfortable products, unhappy customers, and costly returns. With profit margins shrinking, how do you navigate the complex landscape of lingerie fabrics to find the perfect balance?

The right lingerie fabric must balance comfort, durability, aesthetic appeal, and cost-effectiveness. Each material offers unique benefits: lace provides elegance, modal delivers luxurious softness, cotton ensures breathability, while specialty fabrics like mesh, burnout, and bamboo each serve specific functional and aesthetic purposes. Synthetic options like nylon, polyester, and their recycled counterparts offer varying degrees of performance and sustainability.

Finding this balance isn't easy. As a manufacturer with over 30 years in the industry, I've seen countless brands struggle with fabric selection. Let me share what I've learned about the extensive range of lingerie fabrics to help you make informed decisions that will delight your customers without breaking the bank.

Which Lingerie Fabric Offers the Best Balance of Comfort and Cost?

The comfort of lingerie directly impacts customer satisfaction and loyalty. When fabrics irritate skin or trap moisture, returns increase and repeat purchases plummet. How can you avoid this costly mistake while navigating the vast array of available materials?

Natural fibers like cotton provide excellent breathability at moderate cost, while modal and Tencel offer superior softness at higher price points. Bamboo delivers antimicrobial benefits with silky feel, and rayon provides versatility with good drape. Among synthetics, microfiber nylon/spandex blends offer the best comfort-to-cost ratio, while specialty meshes create breathable support at premium prices.

I remember launching a collection using a beautiful but stiff synthetic lace. The samples looked stunning, but customer feedback was brutal—the fabric caused irritation and discomfort. We quickly switched to a bamboo-blend lace that cost just 15% more but reduced returns by 40%. This experience taught me that comfort isn't just a luxury feature—it's a business necessity.

When evaluating comfort, consider both initial feel and performance after multiple washes. Our testing shows that modal and Tencel retain their softness after 50+ wash cycles, while some cheaper synthetics become rough after just 10 washes. Bamboo fabrics often start incredibly soft but may lose some of that luxurious feel over time, still remaining more comfortable than basic polyester blends. This durability factor significantly impacts the perceived value of your products.

| Fabric | Initial Softness (1-10) | Softness After 30 Washes | Breathability | Relative Cost |

|---|---|---|---|---|

| Cotton | 7 | 6 | Excellent | Medium |

| Modal | 9 | 8 | Very Good | High |

| Bamboo | 8 | 7 | Excellent | Medium-High |

| Tencel | 9 | 8 | Very Good | High |

| Rayon | 7 | 6 | Good | Medium |

| Nylon/Spandex | 6 | 4 | Poor | Low |

| Polyester/Spandex | 5 | 3 | Very Poor | Very Low |

| Microfiber (Nylon) | 8 | 6 | Fair | Medium |

| Mesh | 5 | 5 | Excellent | Medium-High |

| Burnout | 6 | 5 | Good | High |

| Recycled Polyester | 5 | 5 | Fair | Medium-High |

| Recycled Nylon | 6 | 5 | Fair | High |

How Does Fabric Performance Impact Your Bottom Line?

Poor fabric performance can destroy your brand reputation overnight. When bras lose shape after a few wears or panties stretch out quickly, customers blame your brand, not the fabric. What performance factors should you prioritize across the diverse range of available materials?

Stretch recovery is critical for bras and shapewear, with spandex blends offering 400-500% stretch while maintaining shape. Durability varies significantly—premium lace may last 50+ wears while cheaper alternatives deteriorate after 15. Specialty fabrics like power mesh provide targeted compression, while burnout creates visual interest with variable opacity. Tencel and bamboo offer excellent moisture management, outperforming most synthetics.

In our factory, we test every fabric batch for stretch recovery, colorfastness, and pilling resistance. Last year, we rejected a shipment of seemingly identical mesh that was 20% cheaper than our standard supplier. Our testing revealed it would lose elasticity after just 10 wash cycles—a short-term savings that would have resulted in long-term customer dissatisfaction.

The relationship between performance and price isn't always linear. Some mid-priced fabrics outperform premium options in specific categories. For example, a bamboo-modal blend at $10/yard often provides better breathability and durability than pure silk at $25/yard. Understanding these nuances helps optimize your fabric selection for both performance and profitability.

| Performance Factor | Best Fabric Choice | Cost Impact | Customer Perception |

|---|---|---|---|

| Stretch & Recovery | Nylon/Spandex, Power Mesh | Medium | High Value (Shape Retention) |

| Durability | Modal/Cotton Blends, Microfiber | Medium-High | High Value (Longevity) |

| Color Retention | Modal, Tencel, Quality Synthetics | High | Medium Value (Visual Appeal) |

| Breathability | Cotton, Bamboo, Mesh | Medium | Very High Value (Comfort) |

| Moisture Management | Bamboo, Tencel, Modal | Medium-High | High Value (Comfort) |

| Compression | Power Mesh, Polyester/Spandex | Medium | High Value (Function) |

| Visual Interest | Burnout, Lace, Mesh | High | Very High Value (Aesthetics) |

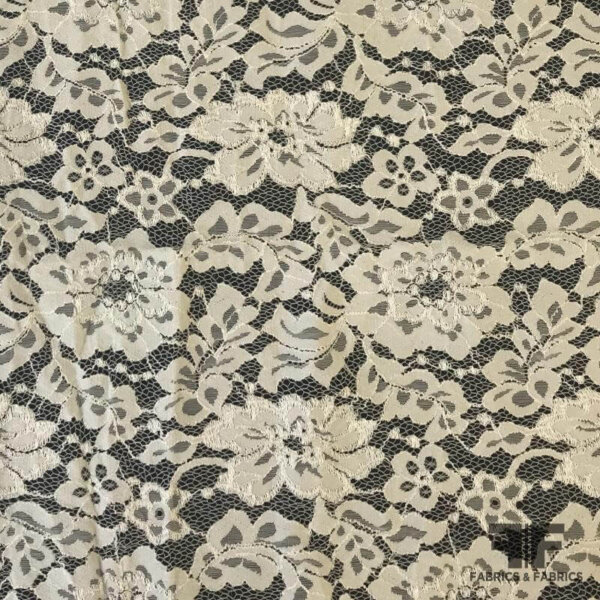

Is Lace Worth the Premium Price for Lingerie Production?

Lace creates an immediate perception of luxury, but its higher cost and delicate nature raise questions about value. Is the premium price justified, or are there smarter alternatives for your lingerie line?

Quality lace costs 30-50% more than basic fabrics but can command price premiums of 100%+ at retail. Different lace types offer varying cost-benefit ratios: Chantilly lace provides delicate elegance at high cost, while stretch lace balances aesthetics with durability at moderate prices. Strategic placement of small lace panels can create luxury appeal without inflating costs.

I've seen brands struggle with lace selection. One client initially chose an expensive French lace for their entire collection, resulting in retail prices too high for their target market. We helped them redesign using strategic lace placement—keeping it visible at necklines and edges while using more affordable fabrics elsewhere. This approach reduced material costs by 40% while maintaining the premium aesthetic.

The quality spectrum for lace is vast. At our factory, we work with laces ranging from $3 to $30 per yard. The difference isn't always visible to consumers, but it becomes apparent in production and wear. Lower-quality laces often cause production challenges—snagging, uneven stretching, and poor recovery—that increase manufacturing costs and defect rates.

Lace Quality Comparison

| Lace Type | Price Range ($/yard) | Durability | Best Applications |

|---|---|---|---|

| Basic Synthetic Lace | $3-7 | Low-Medium | Budget lines, decorative elements |

| Stretch Lace | $8-15 | Medium-High | Everyday bras, panties |

| Chantilly Lace | $15-25 | Medium | Luxury collections, special occasions |

| French Leaver's Lace | $20-30+ | Medium-High | Premium collections, bridal |

| Galloon Lace | $10-20 | Medium | Bra bands, panty edges |

| Raschel Lace | $5-12 | Medium-High | Mid-range collections |

How Do Specialty Fabrics Like Mesh and Burnout Enhance Lingerie Design?

Specialty fabrics like mesh and burnout offer unique aesthetic and functional benefits, but come with their own set of challenges and cost implications. How can these materials elevate your lingerie line while maintaining profitability?

Mesh fabrics provide breathability and visual interest with varying levels of opacity, from sheer to power mesh with compression properties. Burnout creates textural contrast through selective fabric dissolution, commanding premium prices of $12-25/yard. Both require specialized production techniques but can justify 30-50% higher retail prices through perceived design value.

We recently worked with a designer who wanted to incorporate burnout velvet into their collection. The material cost was three times higher than standard fabrics, and production time increased by 40% due to the delicate handling required. However, the finished pieces commanded a 70% price premium at retail, resulting in higher overall margins despite the increased production costs.

Mesh fabrics offer tremendous versatility but require careful selection. Power mesh provides structural support for shapewear and bras, while softer decorative meshes create visual interest without compression. The price range is equally broad—from $4/yard for basic polyester mesh to $18/yard for high-recovery power mesh with specialized finishes.

Specialty Fabric Comparison

| Specialty Fabric | Price Range ($/yard) | Key Properties | Best Applications | Production Complexity |

|---|---|---|---|---|

| Basic Mesh | $4-8 | Lightweight, breathable, sheer | Decorative panels, overlays | Medium |

| Power Mesh | $10-18 | High compression, excellent recovery | Shapewear, supportive bra panels | Medium-High |

| Fishnet | $6-12 | Open structure, high visual impact | Fashion-forward designs, overlays | Medium |

| Burnout Jersey | $12-18 | Variable opacity, textural interest | Fashion bras, loungewear | High |

| Burnout Velvet | $18-25 | Luxurious texture, high-end appearance | Premium collections, robes | Very High |

| Spacer Fabric | $15-22 | 3D structure, breathable, supportive | Molded bra cups, shapewear | High |

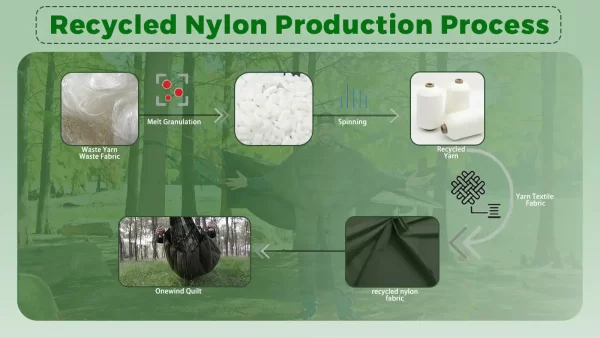

How Do Sustainable Fabrics Compare in Cost and Performance?

Sustainability is no longer just a trend—it's becoming a business requirement. But how do eco-friendly fabrics compare to traditional options in terms of cost, performance, and consumer perception?

Recycled nylon typically costs 20-30% more than virgin nylon with similar performance characteristics, while recycled polyester commands a 15-25% premium. Tencel and bamboo offer excellent sustainability credentials with superior comfort but cost 30-40% more than conventional alternatives. Organic cotton commands a 30-40% premium over conventional cotton with minimal performance differences.

Our factory recently invested in equipment to process recycled fabrics, and the learning curve was steep. Initial production runs had higher defect rates and slower production speeds, increasing costs by nearly 35%. However, after six months of optimization, we've reduced that premium to just 12% while maintaining quality standards that match or exceed conventional materials.

The sustainability landscape is complex, with varying environmental impacts across the lifecycle of different fabrics. For example, recycled polyester requires 59% less energy to produce than virgin polyester but still doesn't biodegrade. Bamboo processing can involve harsh chemicals unless certified as eco-friendly. Tencel (lyocell) offers perhaps the best balance, using a closed-loop production system that recycles 99% of the solvents used. Understanding these tradeoffs helps brands make informed decisions that align with their specific sustainability goals.

Sustainability Impact by Fabric Type

| Fabric | Cost Premium | Water Usage | Energy Consumption | Biodegradability |

|---|---|---|---|---|

| Conventional Cotton | Baseline | Very High | Medium | Yes |

| Organic Cotton | +30-40% | High | Low | Yes |

| Conventional Nylon | Baseline | Medium | High | No |

| Recycled Nylon | +20-30% | Low | Medium | No |

| Conventional Polyester | Baseline | Low | Very High | No |

| Recycled Polyester | +15-25% | Low | Medium | No |

| Bamboo | +25-35% | Low | Medium-High* | Yes |

| Tencel/Lyocell | +30-40% | Low | Medium | Yes |

| Rayon | +10-20% | Medium | Medium-High | Partially |

*Depends significantly on processing method

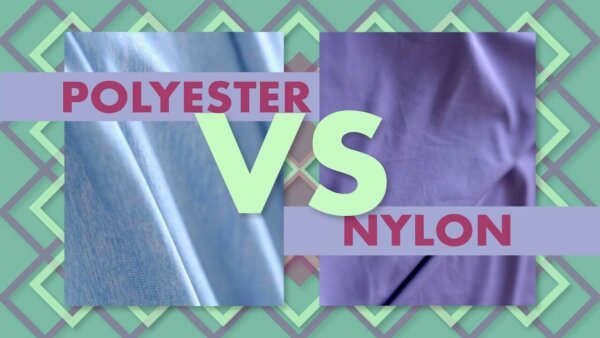

How Do Synthetic Fabrics Compare: Nylon vs. Polyester in Lingerie Applications?

Synthetic fabrics dominate the lingerie industry due to their versatility and cost-effectiveness, but significant differences exist between nylon and polyester. How do these materials compare, and which offers better value for specific lingerie applications?

Nylon provides superior softness, drape, and dye absorption compared to polyester, commanding a 15-25% price premium. Polyester offers better moisture-wicking, faster drying, and greater abrasion resistance at a lower cost. Blends with spandex are essential for both, with nylon/spandex providing better recovery and polyester/spandex offering greater durability and color retention.

I once developed identical bra styles in both nylon/spandex and polyester/spandex for a cost-conscious client. The nylon version cost 18% more but received significantly higher comfort ratings in wear testing. However, after 30 wash cycles, the polyester version maintained its shape and color better. We ultimately created a hybrid design using nylon in areas that contact skin and polyester in structural components—optimizing both comfort and durability.

The recycled versions of these synthetics present interesting tradeoffs. Recycled nylon (often made from fishing nets and carpet) typically costs 20-30% more than virgin nylon but offers nearly identical performance characteristics. Recycled polyester (usually from PET bottles) commands a smaller premium of 15-25% over virgin polyester but may have slightly lower tensile strength. Both recycled options are gaining popularity as brands emphasize sustainability, with consumers increasingly willing to pay premiums for eco-friendly materials.

| Property | Nylon/Spandex | Polyester/Spandex | Recycled Nylon | Recycled Polyester |

|---|---|---|---|---|

| Relative Cost | Medium | Low | High | Medium |

| Softness | Very Good | Fair | Good | Fair |

| Durability | Good | Very Good | Good | Good |

| Moisture Management | Poor | Good | Poor | Good |

| Stretch Recovery | Excellent | Good | Very Good | Good |

| Color Retention | Good | Excellent | Good | Very Good |

| Best Applications | Luxury everyday, skin contact | Activewear, shapewear | Eco-luxury lines | Sustainable basics |

How Do Modal, Tencel, and Rayon Compare for Premium Lingerie?

Cellulosic fibers like modal, Tencel, and rayon offer luxurious softness and excellent drape, making them increasingly popular for premium lingerie. But how do these similar-seeming materials differ in performance and cost?

Modal provides exceptional softness and color brilliance at a premium price point, while Tencel offers superior moisture management and sustainability credentials. Rayon delivers good drape and comfort at a more moderate cost but with less durability. All three require special care in production but command retail price premiums of 40-60% over basic synthetics.

When we first started working with modal fabrics, we experienced significant challenges with shrinkage and tension control during production. After investing in specialized equipment and training, we now achieve excellent results with these premium materials. The learning curve was steep, but the resulting products command significantly higher prices and customer loyalty.

These cellulosic fibers each have distinct advantages. Modal excels in color absorption, creating vibrant, long-lasting hues that maintain their brilliance through multiple washes. Tencel offers superior moisture management, wicking moisture away from the skin 50% more effectively than cotton. Rayon provides excellent drape and a silk-like feel at a more accessible price point, though with reduced durability compared to its more advanced cousins.

| Property | Modal | Tencel/Lyocell | Rayon/Viscose | Bamboo Rayon |

|---|---|---|---|---|

| Relative Cost | High | Very High | Medium | Medium-High |

| Softness | Excellent | Very Good | Good | Very Good |

| Durability | Very Good | Excellent | Fair | Good |

| Moisture Management | Good | Excellent | Fair | Very Good |

| Drape | Excellent | Very Good | Excellent | Very Good |

| Color Brilliance | Excellent | Very Good | Good | Good |

| Sustainability | Good | Excellent | Fair | Good* |

| Best Applications | Luxury everyday, sleepwear | Premium eco-conscious lines | Fashion-forward styles | Comfort-focused collections |

*When processed using eco-friendly methods

Which Fabrics Offer the Best Value for Different Lingerie Types?

Not all lingerie pieces have the same fabric requirements. Bras need structure and support, while panties prioritize comfort and breathability. How should you match fabrics to specific product types for optimal value?

For bras, nylon-spandex blends offer excellent support and shape retention at moderate cost, while microfiber provides superior comfort for everyday styles. Cotton-modal blends provide the best comfort-to-cost ratio for everyday panties, with bamboo excelling for sensitive skin. Shapewear requires high-compression power mesh or polyester-spandex, while sleepwear benefits from modal or Tencel for their exceptional softness.

When we develop new products with clients, we always start by defining the primary function of each piece. A recent client wanted to use the same fabric across their entire collection for brand consistency. We demonstrated how this approach would compromise either performance or cost-efficiency, and instead developed a coordinated fabric strategy that optimized each piece while maintaining visual cohesion.

The most successful lingerie brands understand that strategic fabric selection by product type can significantly impact both margins and customer satisfaction. For example, using premium fabrics in high-visibility areas while using more cost-effective options in less visible sections can reduce material costs by 20-30% without affecting perceived quality. This approach is particularly effective with bras, where cups and front panels can feature premium materials while back bands use more economical, functional fabrics.

Optimal Fabric Selection by Product Type

| Product Type | Primary Requirements | Best Value Fabric | Premium Option | Eco-Friendly Alternative |

|---|---|---|---|---|

| Everyday Bras | Support, Comfort, Durability | Nylon-Spandex Blend | Microfiber with Modal | Recycled Nylon-Spandex |

| Luxury Bras | Aesthetics, Comfort, Uniqueness | Stretch Lace with Microfiber | French Lace with Silk | Tencel with Organic Cotton |

| Everyday Panties | Comfort, Breathability, Durability | Cotton-Spandex Blend | Modal-Spandex Blend | Organic Cotton-Spandex |

| Fashion Panties | Aesthetics, Comfort, Novelty | Microfiber with Lace | Silk with Lace | Bamboo with Recycled Lace |

| Shapewear | Compression, Recovery, Durability | Polyester-Spandex | Power Mesh with Microfiber | Recycled Nylon Compression |

| Sleepwear | Comfort, Breathability, Drape | Cotton-Modal Blend | Pure Modal or Tencel | Bamboo Rayon |

| Activewear Bras | Support, Moisture Management | Polyester-Spandex | Performance Microfiber | Recycled Polyester-Spandex |

Conclusion

Selecting the right fabric for your lingerie line requires balancing multiple factors: comfort, performance, aesthetics, sustainability, and cost. There's no one-size-fits-all solution—each brand must align fabric choices with their specific market positioning, price points, and customer expectations.

By understanding the unique properties and cost implications of different fabrics—from traditional options like cotton and nylon to specialty materials like burnout and mesh to sustainable alternatives like recycled fibers and Tencel—you can make informed decisions that optimize both customer satisfaction and business profitability. Remember that the true cost of fabric extends beyond the price per yard—it includes impacts on production efficiency, product longevity, return rates, and brand perception.