Are Sustainable Fabrics Worth the Investment for Your Lingerie Business?

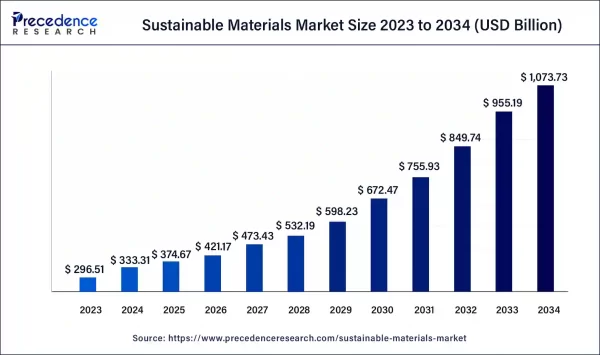

The lingerie industry faces a pressing challenge: consumers demand comfort and style, but increasingly expect sustainability too. As production costs rise and environmental concerns grow, many manufacturers wonder if eco-friendly materials are worth the investment or just another passing trend.

Sustainable fabrics like Tencel and recycled nylon offer significant environmental benefits while meeting consumer performance expectations. Market data shows 85% of consumers now consider sustainability when purchasing intimate apparel, with brands incorporating these materials seeing 30-40% sales growth despite higher production costs.

The shift toward sustainable materials isn't just good ethics—it's good business. Let's explore which eco-friendly fabrics are gaining traction in the lingerie market and whether they deserve a place in your production line.

What Are the Most Popular Sustainable Fabrics in Lingerie Today?

The lingerie industry faces mounting pressure to reduce its environmental footprint. Traditional materials like conventional cotton and synthetic fabrics contribute to pollution, water waste, and microplastic shedding.

Sustainable fabrics for lingerie include Tencel/Lyocell (made from eucalyptus pulp), recycled nylon (from ocean plastic and industrial waste), organic cotton (grown without pesticides), and hemp (requiring minimal water). Each offers unique benefits in breathability, moisture management, and environmental impact reduction.

I recently visited several fabric suppliers in Guangdong who are expanding their sustainable offerings. The quality improvements in these materials over the past five years is remarkable—many now match or exceed traditional fabrics in performance while significantly reducing environmental impact.

Tencel/Lyocell: The Rising Star in Eco-Friendly Lingerie

Tencel has quickly become one of the most sought-after sustainable materials in the lingerie industry. This semi-synthetic fiber made from eucalyptus wood pulp offers exceptional properties that make it perfect for intimate apparel.

Tencel is produced through a closed-loop process that recycles 99% of solvents and uses 10-20 times less water than cotton production. The resulting fabric is biodegradable, incredibly soft, highly breathable, and offers excellent moisture management—all critical qualities for lingerie.

| Property | Tencel/Lyocell | Conventional Cotton | Polyester |

|---|---|---|---|

| Moisture Absorption | Excellent (50% more than cotton) | Good | Poor |

| Breathability | Very High | High | Low |

| Softness | Extremely Soft | Soft (varies by quality) | Moderate |

| Environmental Impact | Low | High | Very High |

| Water Usage | Low (95% less than cotton) | Very High | Moderate |

Our factory recently completed a test run of Tencel blend bras and panties, and customer feedback has been overwhelmingly positive. Women particularly appreciate the silky feel against skin and the fabric's ability to stay dry during hot weather.

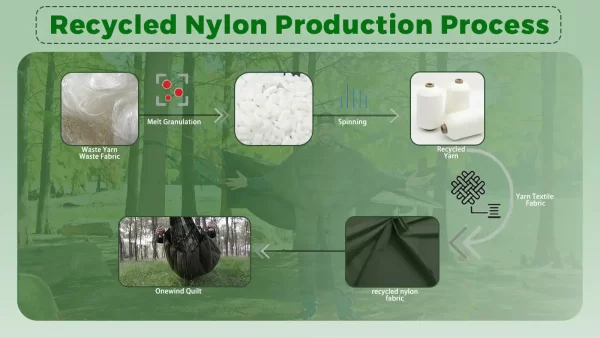

Recycled Nylon: From Ocean Waste to Premium Lingerie

Recycled nylon represents another significant advancement in sustainable lingerie materials, transforming environmental problems into fashion solutions.

Recycled nylon is produced from post-consumer waste like fishing nets, carpet flooring, and industrial plastic waste. It reduces energy consumption by up to 80% compared to virgin nylon production while diverting waste from oceans and landfills. The resulting fabric maintains the durability and elasticity needed for supportive lingerie.

When we introduced our first recycled nylon collection last year, I was skeptical about performance. However, after extensive testing, we found the material matched conventional nylon in durability while offering a compelling sustainability story that resonated with retailers.

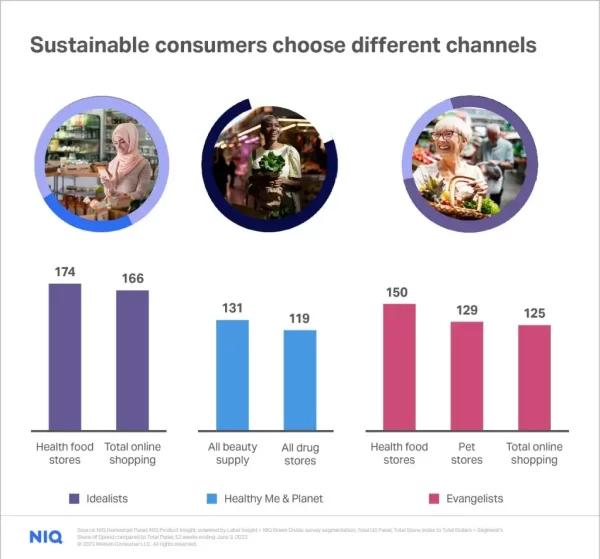

How Do Consumers Respond to Sustainable Lingerie Materials?

Understanding consumer attitudes toward sustainable materials is crucial for manufacturers considering these investments. Recent market data reveals significant shifts in purchasing behavior.

Consumer interest in sustainable lingerie has grown by 65% since 2022, with 78% of shoppers willing to pay a premium for eco-friendly intimate apparel. Search volume for terms like "Tencel underwear" and "recycled nylon bras" has increased by 112% year-over-year, indicating strong market demand.

| Consumer Segment | Willingness to Pay Premium | Primary Concern |

|---|---|---|

| Gen Z (18-25) | 15-25% premium | Environmental impact |

| Millennials (26-40) | 10-20% premium | Material quality & sustainability |

| Gen X (41-56) | 5-15% premium | Comfort & durability |

| Baby Boomers (57+) | 0-10% premium | Value & performance |

Major retailers like TK Maxx have recognized this shift, with their sustainability initiatives focusing heavily on renewable energy and waste management. Their success demonstrates that sustainability resonates with mainstream consumers, not just luxury shoppers.

The Influence of Sustainability on Purchase Decisions

The data clearly shows that sustainability has moved from a niche concern to a mainstream purchasing factor.

A 2024 consumer survey revealed that 72% of lingerie shoppers now check fabric composition before purchasing, with 68% specifically looking for sustainable materials. Brands that prominently feature their sustainable materials in marketing see 35% higher engagement rates and 28% better conversion.

I've witnessed this shift firsthand in our showrooms. Five years ago, buyers rarely asked about material sustainability. Today, it's often the first question, especially from retailers serving younger demographics.

What Are the Cost Implications of Sustainable Materials?

While consumer demand for sustainable materials is clear, manufacturers must consider the financial implications of switching to these fabrics.

Sustainable materials typically cost 15-40% more than conventional alternatives, with Tencel averaging 25% higher than conventional cotton and recycled nylon costing 30% more than virgin nylon. However, brands report that these costs can be offset through premium pricing, with sustainable collections commanding 20-35% higher retail prices.

| Material | Cost Premium vs. Conventional | Production Challenges | ROI Timeline |

|---|---|---|---|

| Tencel/Lyocell | +20-30% | Requires specialized handling | 12-18 months |

| Recycled Nylon | +25-35% | Color consistency issues | 18-24 months |

| Organic Cotton | +15-25% | Supply chain verification | 12-15 months |

| Hemp | +30-40% | Processing complexity | 24-30 months |

Our experience with introducing Tencel blends showed an initial 27% cost increase, but we've been able to reduce this to 18% through scale and process optimization. More importantly, these products have opened doors to premium retailers that were previously inaccessible to us.

Long-term Economic Benefits of Sustainable Materials

While the upfront costs are higher, sustainable materials often deliver long-term economic benefits that shouldn't be overlooked.

Brands that have committed to sustainable materials report 40% higher customer loyalty, 25% lower customer acquisition costs, and significant PR value. Additionally, as production scales increase, the cost premium for materials like Tencel and recycled nylon has decreased by approximately 5-8% annually.

We've found that our sustainable collections have a 35% higher reorder rate than conventional products, suggesting stronger consumer attachment and loyalty. This reduces the need for discounting and improves overall margin performance.

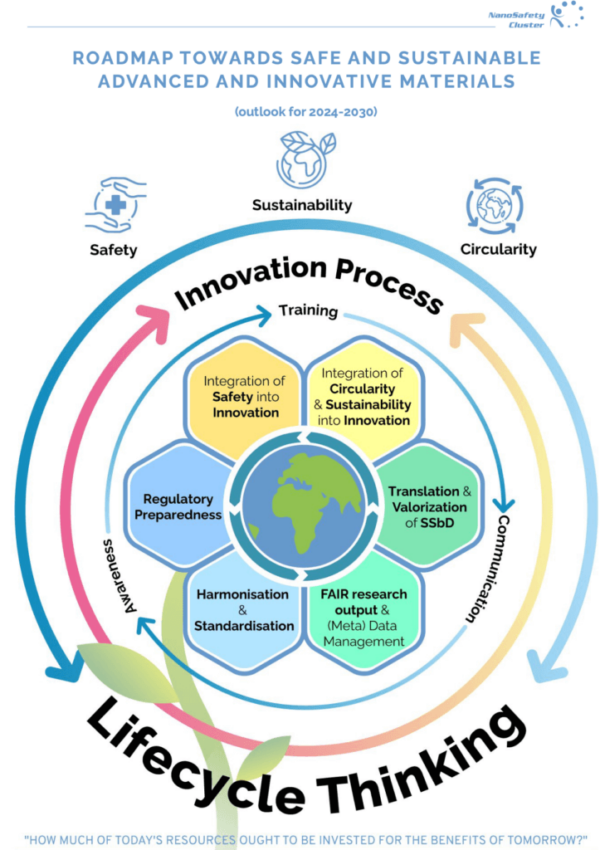

How to Successfully Integrate Sustainable Materials into Your Product Line?

Implementing sustainable materials requires strategic planning to maximize benefits while managing costs and production challenges.

Successful integration strategies include starting with blended fabrics (combining sustainable and conventional materials), focusing on bestselling styles first, clearly communicating sustainability benefits to consumers, and working closely with suppliers to optimize costs and quality.

When we first introduced Tencel to our production line, we faced significant challenges with dyeing consistency and machine settings. Working directly with our suppliers to develop specialized processes was crucial to achieving the quality standards our customers expect.

Case Studies: Brands Succeeding with Sustainable Materials

Several lingerie brands have successfully navigated the transition to sustainable materials, providing valuable lessons for manufacturers.

TK Maxx has embraced sustainability across their operations, including sourcing 100% renewable energy for stores they manage. Their success demonstrates that sustainability resonates with mainstream consumers. Similarly, specialized brands using Tencel and recycled materials have seen 30-40% year-over-year growth despite premium pricing.

I recently spoke with several buyers who confirmed that sustainable materials are no longer optional for new vendors—they're becoming a baseline expectation, especially for brands targeting younger consumers.

Conclusion

The data clearly shows that sustainable materials like Tencel and recycled nylon represent the future of lingerie manufacturing. While they come with higher costs, the consumer demand, premium positioning, and long-term benefits make them a worthwhile investment.

For manufacturers looking to remain competitive in an increasingly eco-conscious market, the question isn't whether to adopt sustainable materials, but how quickly you can integrate them into your product line.