Seamless vs. Bonded Underwear: A Strategic Choice for Brands

Choosing the right underwear production technology is crucial for brand success. Among the many options, seamless and bonded underwear technologies each have their advantages, but making the wrong choice can lead to wasted costs, quality issues, and poor market response.

The choice between seamless or bonded underwear technology primarily depends on product positioning, target market, and performance requirements. Seamless underwear excels with its automated production and comfort at lower costs, while bonded underwear offers advantages in invisibility, body-hugging fit, and premium appearance, albeit at a higher price point.

Underwear manufacturing technology has undergone tremendous changes in recent years. Once, traditional sewing was the only option, but now seamless and bonded technologies occupy important positions in the high-end and mid-range markets. As an underwear manufacturer, I've witnessed firsthand how these technologies have reshaped the market and seen the confusion many brands face when choosing the best technological approach. Let me guide you through the characteristics and differences of these two technologies.

Seamless Underwear Technology: How Does It Actually Work?

In the underwear industry, production processes determine product quality and cost. Although seamless underwear is a common term, its complex production process is often misunderstood, leading to biases in brand procurement decisions.

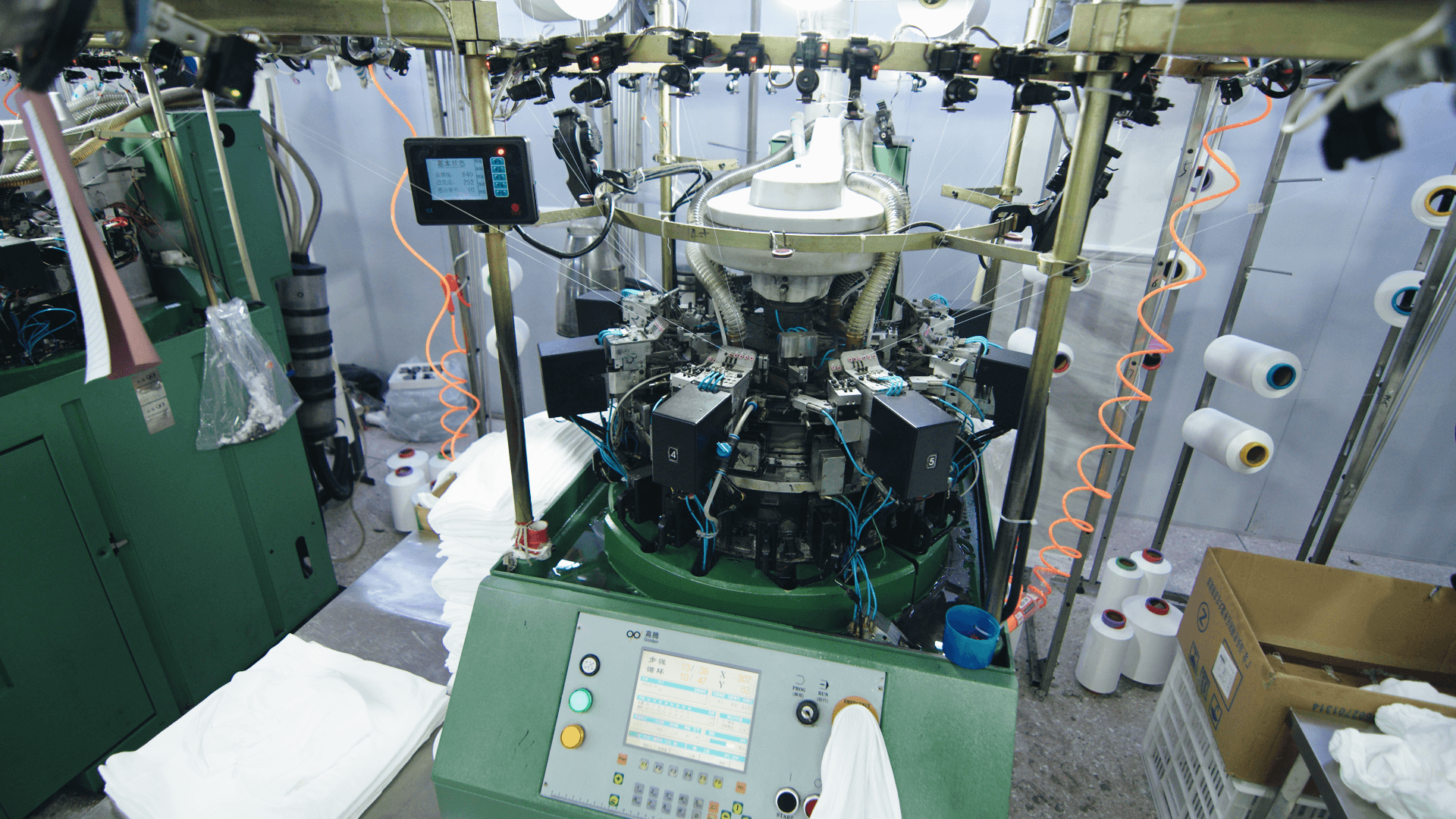

Seamless underwear (also called seamfree) is primarily created using specialized circular knitting machines that produce a fabric tube in one operation, eliminating the need for side seams. This process significantly reduces seams, improves wearing comfort, and achieves a higher degree of automated production, thereby reducing labor costs.

When I first entered the underwear industry, I also had misconceptions about seamless technology. Many people believe seamless underwear has no seams at all, but in reality, while the main structure is seamless, areas like the waistband and leg openings still require subsequent processing and sewing. Understanding this is very important for brands when communicating with suppliers.

Circular knitting machine technology is at the core of seamless underwear production. These machines can knit a complete underwear main structure in one operation according to preset programs, greatly simplifying traditional cutting and sewing processes. At HAVING, we use Italian Santoni and Korean NERI equipment - these top-tier circular machines can produce extremely fine seamless products.

Seamless Underwear Production Process

| Production Stage | Process Description |

|---|---|

| Material Preparation | Selection of yarns suitable for circular machine knitting, such as nylon, cotton, elastic yarn, etc. |

| Circular Machine Knitting | Computer-controlled circular machine knits the fabric tube in one operation |

| Dyeing and Finishing | Dyeing and shape-setting of the knitted tubes |

| Cutting | Cutting the tubes into the required shapes according to design |

| Waistband and Leg Opening Treatment | Adding elastic bands or using coverstitch machines for edge treatment |

| Inspection and Packaging | Quality inspection and packaging of finished products |

Material selection for seamless underwear is relatively limited, which is an important factor for brands to consider. The most commonly used materials include cotton, nylon, and polyester, which need to have sufficient elasticity and durability to work well on circular machines. At HAVING, we've found that combinations of nylon and spandex provide the best body-hugging feel and elastic recovery, particularly suitable for sports bras and everyday underwear.

One unique advantage of seamless underwear is its versatility. Beyond traditional underwear, this technology is widely applied in the field of functional underwear. We've successfully developed thermal underwear lines using Merino wool, which is difficult to achieve with traditional sewing techniques because seams would affect overall thermal performance. This provides an important differentiation opportunity for brands pursuing functional products.

Bonded Underwear Technology: Why Is It So Popular in the High-End Market?

Bonded underwear represents a revolution in underwear manufacturing technology, but its high cost and complex processes often make brands hesitate. Understanding its true value is key to making informed procurement decisions.

Bonded underwear uses heat-activated adhesive bonding to replace traditional stitched seams when joining fabrics, creating gap-free, seamless connections. The greatest advantage of this technology is achieving truly "invisible underwear" (No VPL - Visible Panty Line), providing a more body-hugging, comfortable wearing experience that's especially suitable for wearing under fitted clothing.

Early in my career, my first impression of bonding technology was one of amazement. We were developing products for a high-end lingerie brand, and the client specifically requested panties that would be completely invisible under tight skirts. Traditional technology couldn't achieve this goal, and the results from bonding technology were stunning—the edges of the underwear almost merged with the skin, leaving absolutely no visible lines under tight clothing.

The core of bonded underwear lies in its unique heat-activated adhesive bonding technology. Unlike ordinary glue, this special adhesive melts at high temperatures and penetrates fabric fibers, forming a strong yet soft bond when cooled. This creates a seaming method that maintains both structural strength and fabric softness.

Bonded Underwear Production Process

| Production Stage | Process Description |

|---|---|

| Material Selection | Choosing fabrics suitable for heat bonding, typically nylon-elastane blends |

| Cutting | Precise cutting of fabric components, requiring greater accuracy |

| Heat-Activated Tape Preparation | Selecting appropriate width and strength of heat-activated tape based on seam type |

| Heat Bonding | Using heat press machines to bond fabrics with heat-activated tape |

| Edge Treatment | Using laser cutting or special equipment to treat edges, ensuring invisible effect |

| Quality Testing | Testing bonding strength and elastic recovery ability |

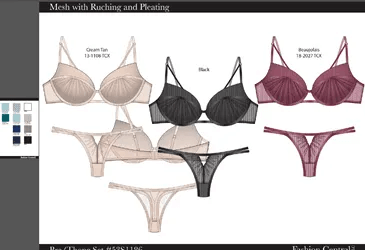

Material options for bonded underwear are more extensive than for seamless underwear, which is one of its significant advantages. From lightweight nylon blends to high-end lace, virtually any material that can withstand the heat treatment process can be used with bonding technology. This allows brands to offer more diversified product lines while maintaining invisible characteristics. At HAVING, we've successfully developed bonded underwear in various materials including lace, stretch satin, and microfiber to meet different consumer needs.

The application areas for bonded underwear continue to expand. Initially, this technology was mainly used for high-end panties, but now it has extended to sports bras, shapewear, and swimwear. Especially during high-intensity exercise, the invisible characteristic of bonding technology can effectively reduce friction and irritation, enhancing athletic performance. Our experience working with a well-known fitness apparel brand proves that bonded sports bras can become star products for brands. Despite higher costs, consumers are willing to pay a premium for their unique advantages.

Cost and Value Analysis: Which Technology Fits Your Budget?

In underwear procurement decisions, cost is often the primary consideration. However, focusing solely on unit price while ignoring overall value can lead to incorrect strategic decisions and lost market opportunities.

Seamless underwear typically costs 15-30% less than bonded underwear, mainly due to its highly automated production process and lower labor requirements. In contrast, bonded underwear requires more specialized technicians and equipment, but its high added value and differentiation advantages may bring higher retail prices and profit margins.

Years ago, when working with a mid-range lingerie brand, they initially chose all seamless products based on cost. However, they noticed competitors created more diverse product lines by mixing seamless and bonded technologies. On our advice, they tried launching a small bonded underwear series as a premium line. Although costs increased by about 25%, retail prices were raised by 40%, ultimately improving overall profit margins.

Understanding the cost structure of both technologies is essential for developing informed procurement strategies. The cost advantage of seamless underwear mainly comes from production efficiency: a high-end circular machine can produce hundreds of underwear bodies per day, significantly reducing labor costs. In contrast, bonded underwear requires skilled technicians operating heat bonding equipment and demands more precise cutting and processing.

Cost Structure Comparison

| Cost Factor | Seamless Underwear | Bonded Underwear |

|---|---|---|

| Equipment Investment | High (circular knitting machines cost $80,000-150,000) | Medium (heat press machines cost $10,000-30,000) |

| Labor Costs | Low (high automation level) | High (requires skilled technicians) |

| Material Costs | Medium (specific yarns required) | Medium to High (plus adhesive materials) |

| Production Efficiency | High (fast production cycle) | Low to Medium (more manual processing) |

| Minimum Order Quantity | Higher (typically 1,000+ per style/color) | Lower (can be as low as 300 pieces) |

Beyond direct production costs, brands should consider the market positioning value of each technology. At HAVING, we've observed that bonded underwear commands an average retail price premium of 30-50% over comparable seamless products. This is particularly evident in the luxury and premium athletic markets, where consumers prioritize performance and aesthetics over price.

The minimum order quantity (MOQ) factor also deserves consideration. While seamless technology offers better unit economics, it typically requires higher MOQs due to machine setup costs and yarn minimums. For emerging brands or those testing new designs, bonded technology can sometimes be more accessible despite the higher unit cost, as it allows for smaller production runs.

Quality and Performance Differences: Which Technology Delivers Better Products?

Quality considerations often outweigh cost in long-term brand strategy. Choosing the wrong technology can lead to high return rates, damage to brand reputation, and lost customer loyalty - costs far exceeding any production savings.

Seamless underwear generally offers superior comfort and durability for everyday wear, with excellent stretch recovery and breathability. Bonded underwear excels in creating smooth silhouettes under clothing and can offer enhanced support in structured garments like shapewear. Each technology serves different performance needs and target consumers.

I recall working with an athletic wear brand that initially insisted on bonded technology for their entire sports bra line based solely on its premium market positioning. After extensive wear testing, we discovered that while bonded construction excelled for light-impact activities where invisibility was paramount, seamless construction provided better support and moisture management for high-impact activities. We ultimately developed a hybrid line that used each technology where it performed best.

Quality assessment for underwear must consider both immediate appearance and long-term performance. At HAVING, we conduct extensive testing beyond industry standards, including 30-wash durability tests to simulate a product's entire lifecycle. This testing has revealed distinct performance differences between the technologies.

Performance Comparison by Application

| Application | Seamless Advantage | Bonded Advantage |

|---|---|---|

| Everyday Underwear | Better breathability, cost-effective durability | No visible lines under clothing, smoother silhouette |

| High-Impact Sports Bras | Better support, moisture-wicking, durability | Reduced chafing, streamlined aesthetics |

| Shapewear | Graduated compression, better breathability | Smoother transitions, invisible under clothing |

| Luxury Lingerie | Comfort for extended wear, better value | Premium aesthetics, compatibility with delicate fabrics |

| Thermal Underwear | Superior insulation, better for various fibers | Flatter seams, better layering under clothing |

One critical quality aspect often overlooked is wash durability. In our testing lab at HAVING, we've found that seamless underwear generally maintains its shape and elasticity better after repeated washing. The knitted structure distributes stress more evenly, resulting in fewer deformations over time. Bonded underwear, while initially presenting a smoother appearance, can experience adhesive degradation if not properly engineered or if consumers don't follow care instructions.

The comfort equation differs significantly between the technologies. Seamless underwear typically conforms better to body movements and provides more "give" during activity. The absence of bulky seams reduces irritation, particularly in sensitive areas. Bonded underwear, while smooth along seam lines, can sometimes feel stiffer and less forgiving, though recent advances in adhesive technology are narrowing this gap.

For brands, these quality differences translate directly to customer satisfaction and repeat purchases. Our customer feedback data indicates that first-time consumers are often drawn to bonded underwear's aesthetics, but long-term loyalty is frequently driven by the everyday comfort of well-designed seamless products. The ideal strategy often involves offering both technologies to meet different customer needs and usage occasions.

Market Trends and Consumer Preferences: What Are Buyers Looking For?

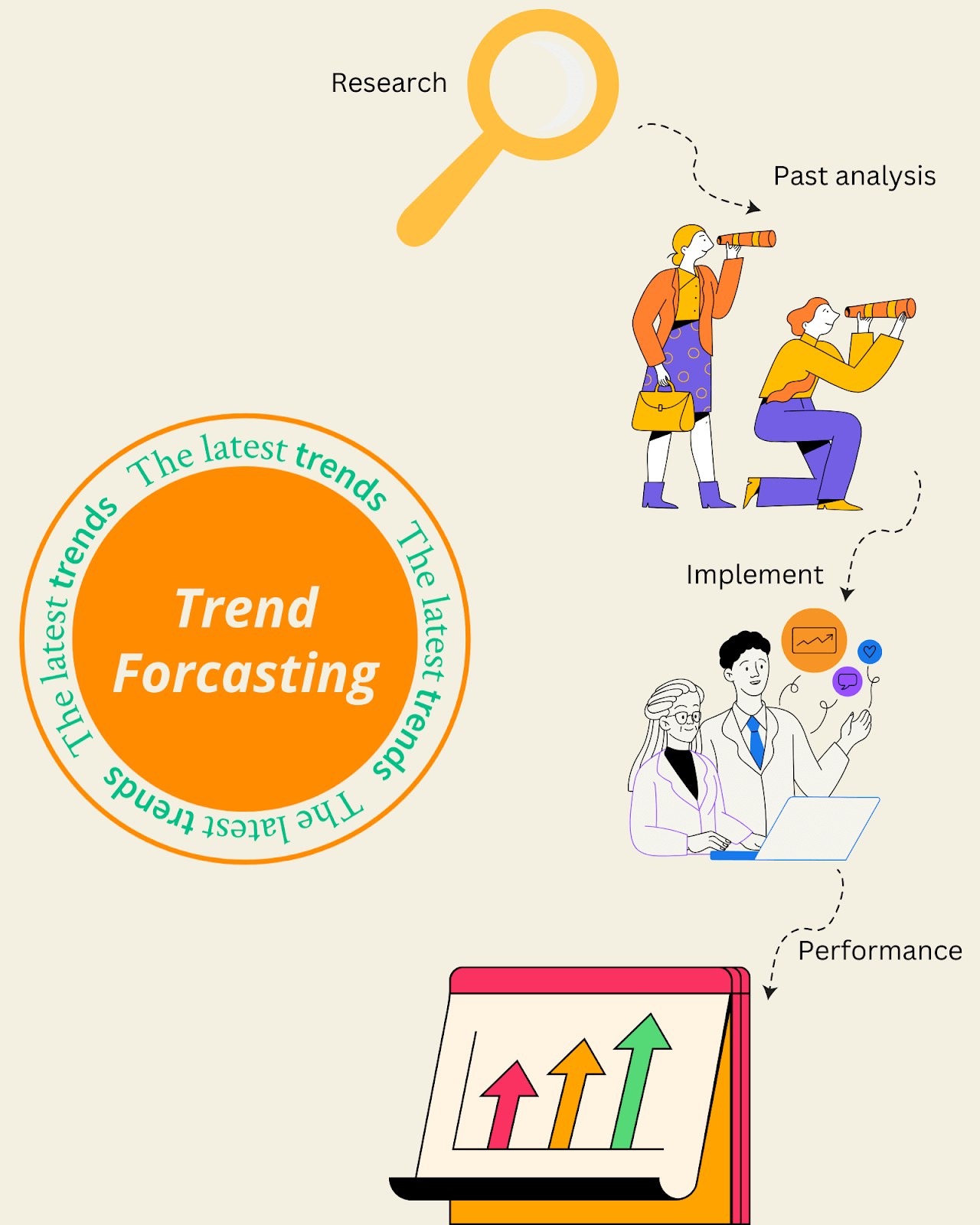

Understanding market trends is essential for strategic underwear sourcing decisions. Consumer preferences are evolving rapidly, and brands that anticipate these shifts gain significant competitive advantages.

Current market data shows growing consumer interest in both seamless and bonded technologies, but for different reasons. Seamless remains the volume leader for everyday underwear, valued for comfort and accessibility. Bonded underwear is experiencing faster percentage growth, especially in premium and performance segments where its invisible benefits command higher margins.

I recently attended a major textile innovation exhibition where underwear technology was a focal point. What struck me was the convergence of these previously separate technologies. Leading manufacturers were showcasing hybrid approaches that combined the comfort of seamless construction with bonded elements for critical areas like waistbands and leg openings. This trend suggests that the future isn't about choosing one technology over another, but strategically integrating both.

Consumer preference data reveals interesting demographic patterns. Younger consumers (18-34) show stronger preference for bonded technology, valuing its modern aesthetics and invisibility under today's fashion trends. Meanwhile, seamless technology maintains stronger loyalty among consumers aged 35+, who prioritize comfort and durability. This generational divide presents important segmentation opportunities for brands.

Market Growth Projections by Segment (2022-2027)

| Market Segment | Seamless Growth | Bonded Growth |

|---|---|---|

| Everyday Underwear | 5-7% annually | 12-15% annually |

| Athletic/Performance | 9-12% annually | 18-22% annually |

| Luxury/Premium | 3-5% annually | 10-14% annually |

| Shapewear | 6-8% annually | 15-18% annually |

| Sustainable/Eco | 14-18% annually | 8-10% annually |

Sustainability is becoming an increasingly important factor in underwear purchasing decisions. Here, the technologies present different environmental profiles. Seamless production generally results in less fabric waste since the garment is knit to shape. However, the synthetic fibers commonly used in seamless production can raise concerns about microplastic shedding. Bonded technology creates more cutting waste but can utilize a wider range of sustainable materials, including organic and recycled options.

At HAVING, we're seeing growing interest in eco-friendly versions of both technologies. We've successfully developed seamless underwear using recycled nylon and organic cotton blends, and our R&D team has recently qualified a new generation of water-based adhesives for bonded underwear that eliminate harmful chemicals while maintaining performance. Brands that emphasize sustainability should consider these advances in their sourcing decisions.

The rise of direct-to-consumer (DTC) underwear brands has also influenced technology preferences. These digitally-native brands often favor bonded technology for its premium positioning and photogenic qualities, which perform well in social media marketing. Traditional retail brands tend to maintain a more balanced portfolio, recognizing the importance of seamless for everyday value propositions.

Sourcing Strategies: How to Choose the Right Supplier for Each Technology?

Finding the right manufacturing partner is critical to your underwear line's success. Different technologies require different expertise, equipment, and quality control processes - mistakes in supplier selection can be costly and time-consuming.

For seamless underwear, prioritize suppliers with modern circular knitting machinery and strong yarn sourcing capabilities. For bonded underwear, look for technical expertise in adhesive application, precision cutting, and extensive quality testing. In both cases, proven experience with your specific product category is more valuable than general apparel manufacturing capability.

One of my most educational experiences came early in my career when I visited a factory that claimed expertise in both technologies. Their seamless operation was impressive - modern Italian machines, skilled technicians, and comprehensive testing. However, their bonded department consisted of a single heat press machine in a corner with untrained operators. The resulting products were completely unacceptable, with delamination occurring after just a few washes. This taught me that true dual-capability suppliers are rare and require careful verification.

When evaluating potential suppliers, consider these technology-specific factors:

Supplier Evaluation Criteria

| Evaluation Factor | Seamless Supplier Indicators | Bonded Supplier Indicators |

|---|---|---|

| Key Equipment | Modern Santoni or equivalent machines, dyeing facilities | Precision heat presses, laser cutting capability |

| Technical Expertise | Programming skill for knitting patterns, color consistency | Adhesive knowledge, precise temperature control |

| Quality Testing | Stretch recovery, colorfastness, dimension stability | Bond strength, wash durability, edge finish quality |

| Minimum Orders | Typically higher (1,000+ per style) | Can be lower (300-500 per style) |

| Development Timeline | Longer for initial development (4-6 weeks) | Faster prototyping possible (2-3 weeks) |

Supplier geographical location is another important consideration. Seamless production has traditionally been concentrated in certain manufacturing hubs - notably China, Italy, and Turkey - where specialized equipment and technical expertise cluster. Bonded technology, while still requiring expertise, has a somewhat broader geographical distribution. At HAVING, we've invested heavily in both technologies at our facilities in China, which gives us unique capabilities to offer integrated solutions.

The development process varies significantly between the technologies. Seamless development typically requires more upfront investment in programming and sampling, with changes being more complex to implement once production begins. Bonded development can be more iterative, allowing for adjustments later in the process. Brands should align their development timeline expectations accordingly.

For emerging brands or those making their first foray into these technologies, supplier support capabilities are particularly important. Look for manufacturers who offer design assistance, material recommendations, and market insights rather than simply executing specifications. The right partner should function as an extension of your technical team, especially when you're exploring unfamiliar technologies.

Strategic Integration: How to Balance Both Technologies in Your Product Line?

The most successful underwear brands aren't choosing between seamless and bonded technologies - they're strategically integrating both to create comprehensive product offerings that meet diverse consumer needs.

Rather than viewing seamless and bonded as competing technologies, consider them complementary tools in your product development arsenal. Seamless can serve as your everyday, accessible price point products with comfort advantages, while bonded can elevate your premium offerings where invisible aesthetics command higher margins.

I've worked with numerous brands on portfolio strategy, and the most successful approaches involve thoughtful segmentation. One lingerie brand we partner with maintains a "good-better-best" architecture: their mass-market retailers receive primarily seamless products at competitive price points, their own stores and department stores get a mix with bonded elements incorporated into mid-tier products, and their luxury line for high-end boutiques features extensively bonded construction with premium materials.

This strategic segmentation allows brands to serve different retail channels and consumer segments while maintaining clear price-value relationships. It also creates natural upgrade paths for consumers as their preferences and purchasing power evolve.

Strategic Integration Framework

| Brand Position | Entry-Level Products | Core Products | Premium Products |

|---|---|---|---|

| Mass Market | Basic seamless | Patterned seamless | Hybrid with bonded elements |

| Mid-Range | Advanced seamless | Hybrid construction | Simple bonded designs |

| Premium | Premium seamless | Advanced bonded | Luxury fully bonded |

| Performance | Basic seamless | Technical seamless | Bonded performance |

Hybrid products represent an exciting frontier in underwear innovation. These designs combine the strengths of both technologies - for example, using seamless construction for the main body where comfort is paramount, with bonded edges at waistbands and leg openings to eliminate visible lines. At HAVING, we've developed patented processes to combine these technologies effectively without compromising durability or comfort.

The seasonal planning cycle presents another opportunity for strategic integration. Many brands we work with maintain a consistent core of seamless essentials year-round, while using bonded technology for seasonal fashion collections where the higher margins can better absorb the development costs of new colors and designs. This approach optimizes both production efficiency and market excitement.

Channel strategy should also inform your technology mix. Direct-to-consumer channels can more effectively communicate the premium benefits of bonded technology and justify higher price points. Wholesale channels, particularly mass retailers, typically favor the value equation of seamless products. However, education can help bridge this gap - we've helped several brands develop in-store displays that effectively demonstrate the invisible benefits of bonded products.

When planning your underwear line, consider starting with a core foundation of proven seamless styles while introducing bonded options strategically. Track performance metrics carefully, not just sales volume but also margins, return rates, and customer feedback. This data will guide your evolving technology balance over time. At HAVING, we partner with brands to analyze this performance data and continuously refine the technology mix to maximize overall program success.

Future Innovations: What's Next in Underwear Technology?

The underwear manufacturing landscape continues to evolve rapidly, with new innovations emerging that will further blur the lines between traditional technologies. Brands that anticipate these changes can gain significant competitive advantages.

Emerging innovations include bio-based adhesives for more sustainable bonded underwear, digital knitting advances that enhance seamless capabilities, and hybrid technologies that combine multiple construction methods in single garments. Smart textiles and personalization are also poised to transform the underwear category in coming years.

In our innovation lab at HAVING, we're constantly testing new approaches. Recently, we've been experimenting with programmable yarns that allow seamless underwear to provide different compression levels in different zones without changing the overall construction. This technology could revolutionize shapewear by creating invisible support that's knit directly into everyday underwear.

Sustainability innovations are particularly exciting. The traditional adhesives used in bonded underwear have often contained chemicals of concern, but a new generation of water-based, biodegradable adhesives is changing this. Similarly, new recycled and bio-based yarns are enhancing the environmental profile of seamless underwear while maintaining performance.

Emerging Technology Trends

| Innovation Area | Technology Development | Market Impact |

|---|---|---|

| Sustainable Materials | Bio-based adhesives, recycled nylon yarns | Enhanced eco-credentials without performance compromise |

| Digital Knitting | Advanced programming for complex zone engineering | More sophisticated seamless designs with targeted support |

| Hybrid Construction | Combined technologies in single garments | Best-of-both-worlds performance without compromises |

| Smart Textiles | Integrated sensors and responsive materials | Health monitoring and adaptive performance features |

| On-Demand Manufacturing | Rapid seamless production with minimal setup time | Reduced minimums, faster market response, less inventory |

The integration of smart textile capabilities is particularly intriguing for performance underwear. We're seeing early applications of moisture-responsive textiles that can adapt their properties based on sweat levels, enhancing comfort during athletic activities. Looking further ahead, the incorporation of flexible sensors into intimate apparel presents opportunities for health monitoring in a garment category that maintains consistent skin contact.

Manufacturing innovations are also changing the business model for underwear production. Newer generations of seamless machines offer significantly faster setup times, potentially reducing minimum order quantities and enabling more responsive production. This could eventually lead to more on-demand manufacturing approaches, reducing inventory risk for brands and opening opportunities for greater personalization.

The future likely belongs to brands that remain technology-agnostic and adaptable. Rather than committing exclusively to either seamless or bonded technologies, forward-thinking companies are building flexible supply chains that can leverage the best emerging innovations regardless of their technical categorization. At HAVING, we're investing in this flexible approach, maintaining expertise across the full spectrum of underwear construction technologies.

Conclusion

Choosing between seamless and bonded underwear technology isn't an either-or decision but a strategic opportunity to diversify your product offerings and target different consumer segments. By understanding the distinct advantages of each technology - seamless for comfort and value, bonded for invisibility and premium positioning - brands can develop balanced portfolios that maximize both market reach and profit margins.

Get a Free Quote for Your Underwear Projects